Electric compressor

An electric compressor, compression chamber technology, used in machines/engines, liquid fuel engines, rotary piston machines, etc., to address the inability to adequately support the orbiting scroll, the increased size and weight of the compressor, and the number of compressor parts Increase and other problems, to achieve the effect of increasing the diameter, increasing the compression capacity, and suppressing the axial leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

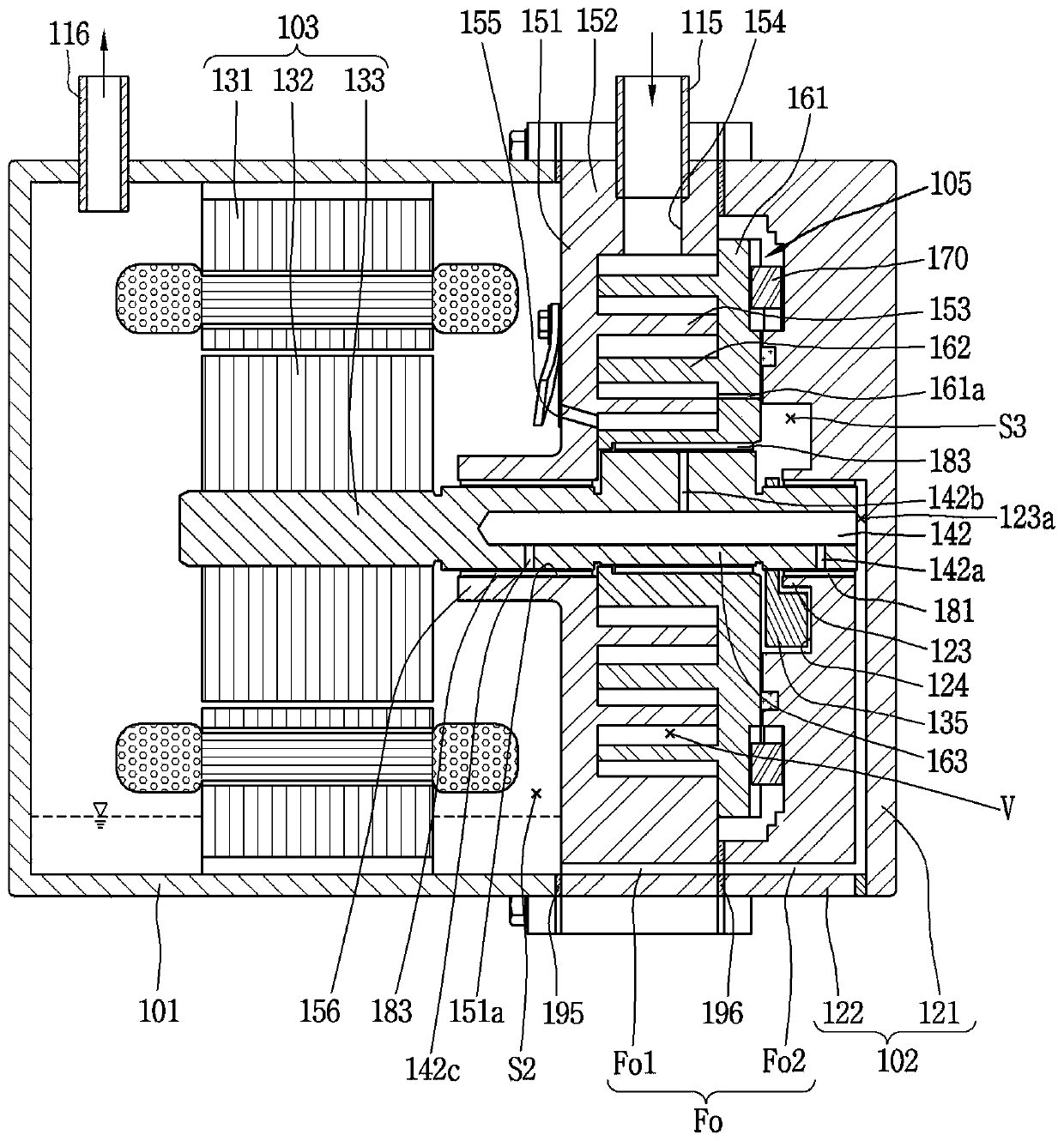

[0056] Next, the electric compressor of the present invention will be described in detail according to an embodiment shown in the drawings.

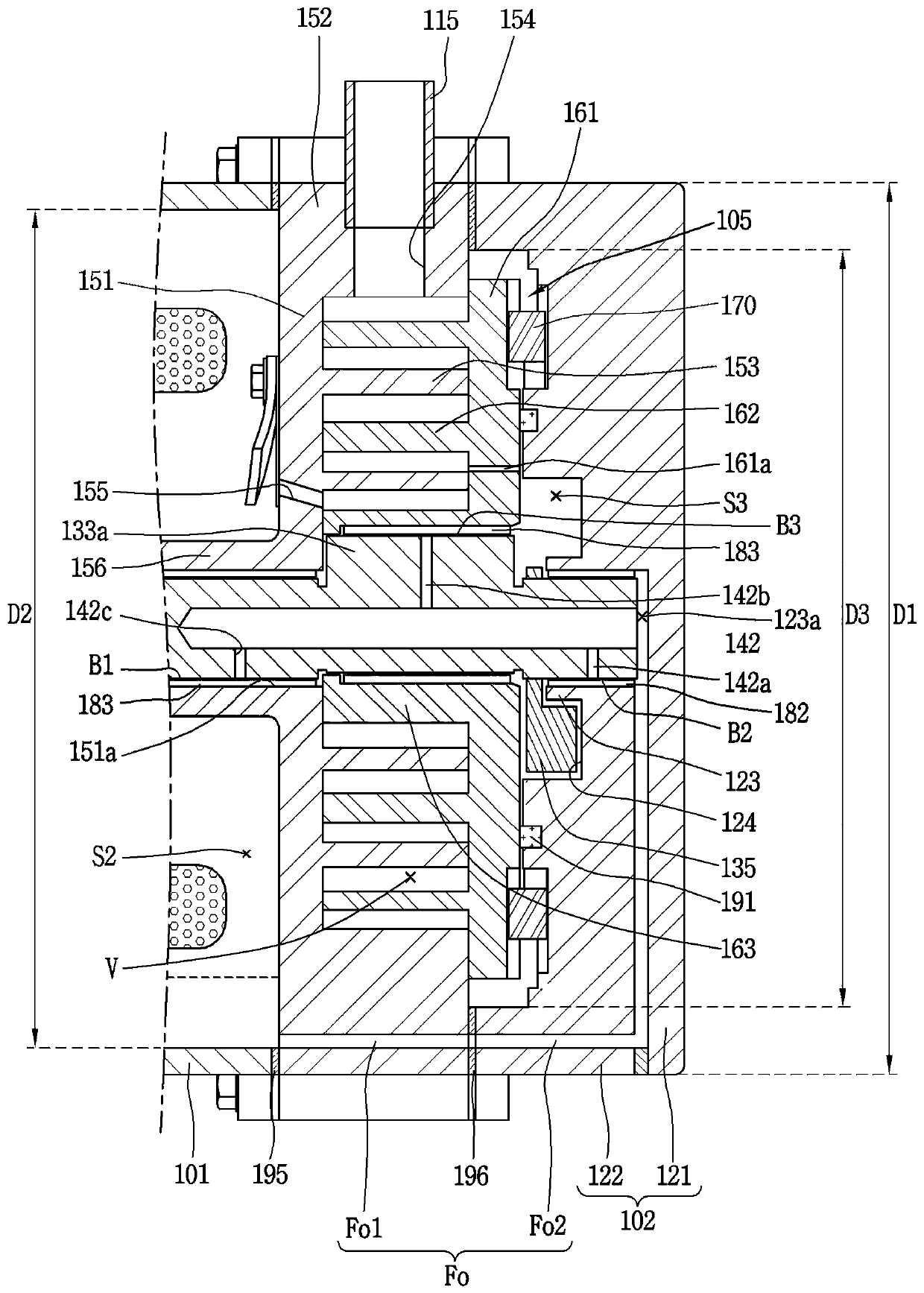

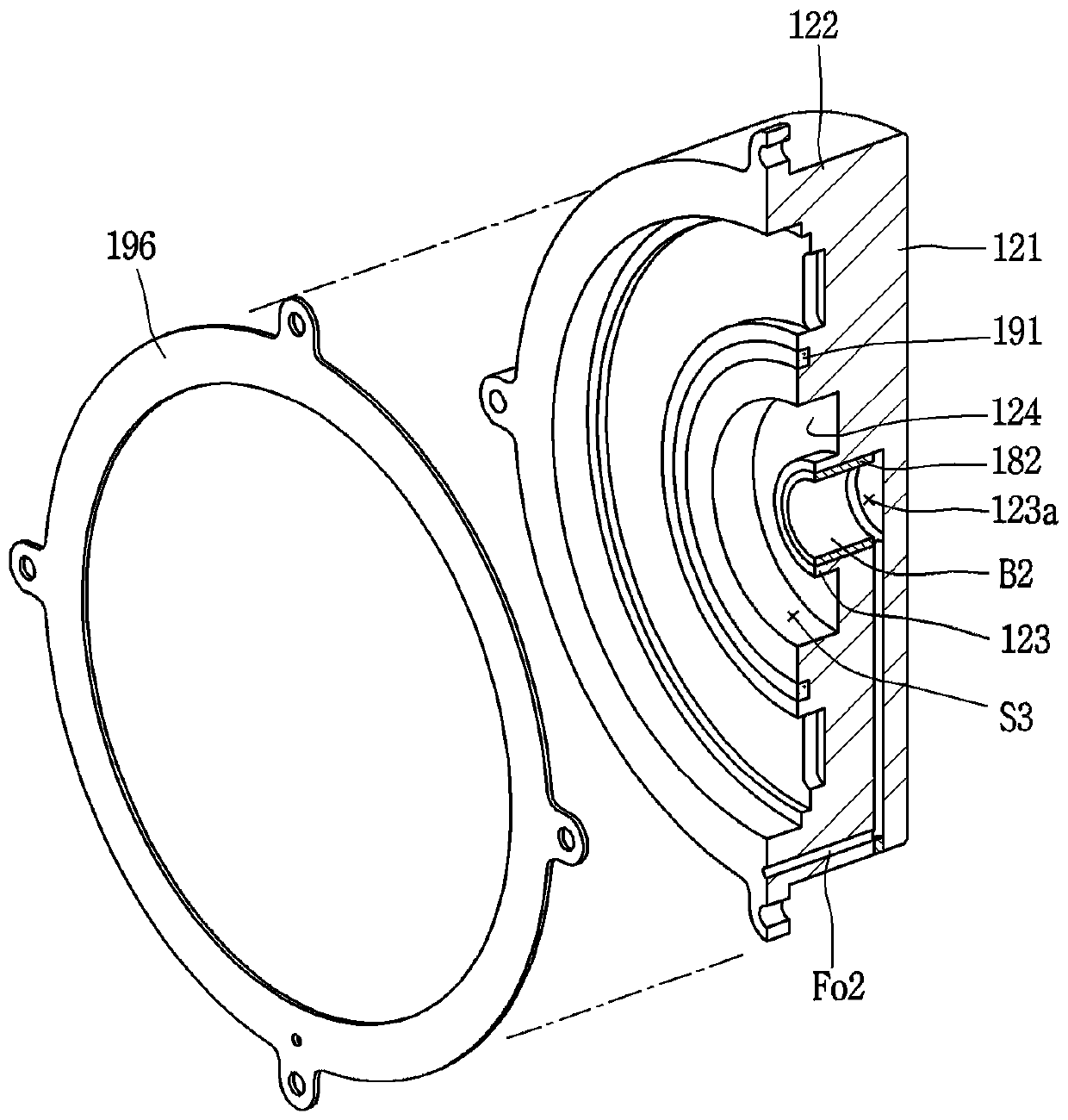

[0057] figure 1 It is a sectional view showing the inside of the electric compressor of the present invention, figure 2 will be figure 1 An enlarged and shown cross-sectional view of the periphery of the compression portion shown.

[0058] As shown in the figure, the electric scroll compressor of this embodiment (hereinafter referred to as the electric compressor) includes: a drive motor 103, which is fixed inside the cover body 101 as an electric part; and the frame 102 is provided on one side of the compression part 105 and supports the compression part 105 while playing a role of a shell together with the cover 101. Such an electric compressor is a high-pressure compressor as the refrigerant discharged from the compression unit 105 is discharged to the outside through the internal space of the cover 101 .

[0059] Along with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com