A grounding method of the outside metal parts of the electronic products

A technology of electronic products and grounding methods, which is applied in the direction of electrical components, conductive adhesive connections, static electricity, etc., to achieve the effects of firm grounding, stable resistance, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

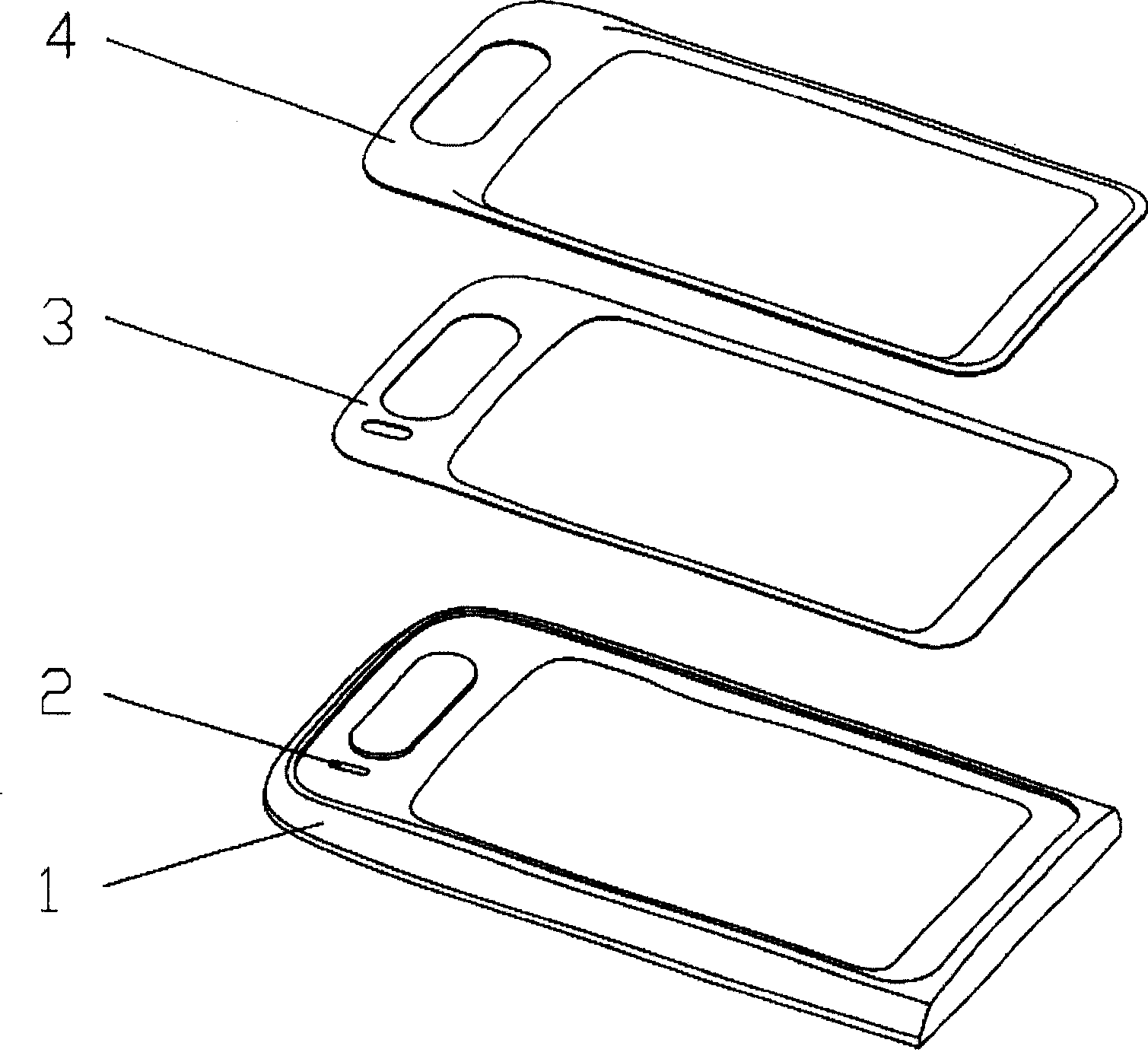

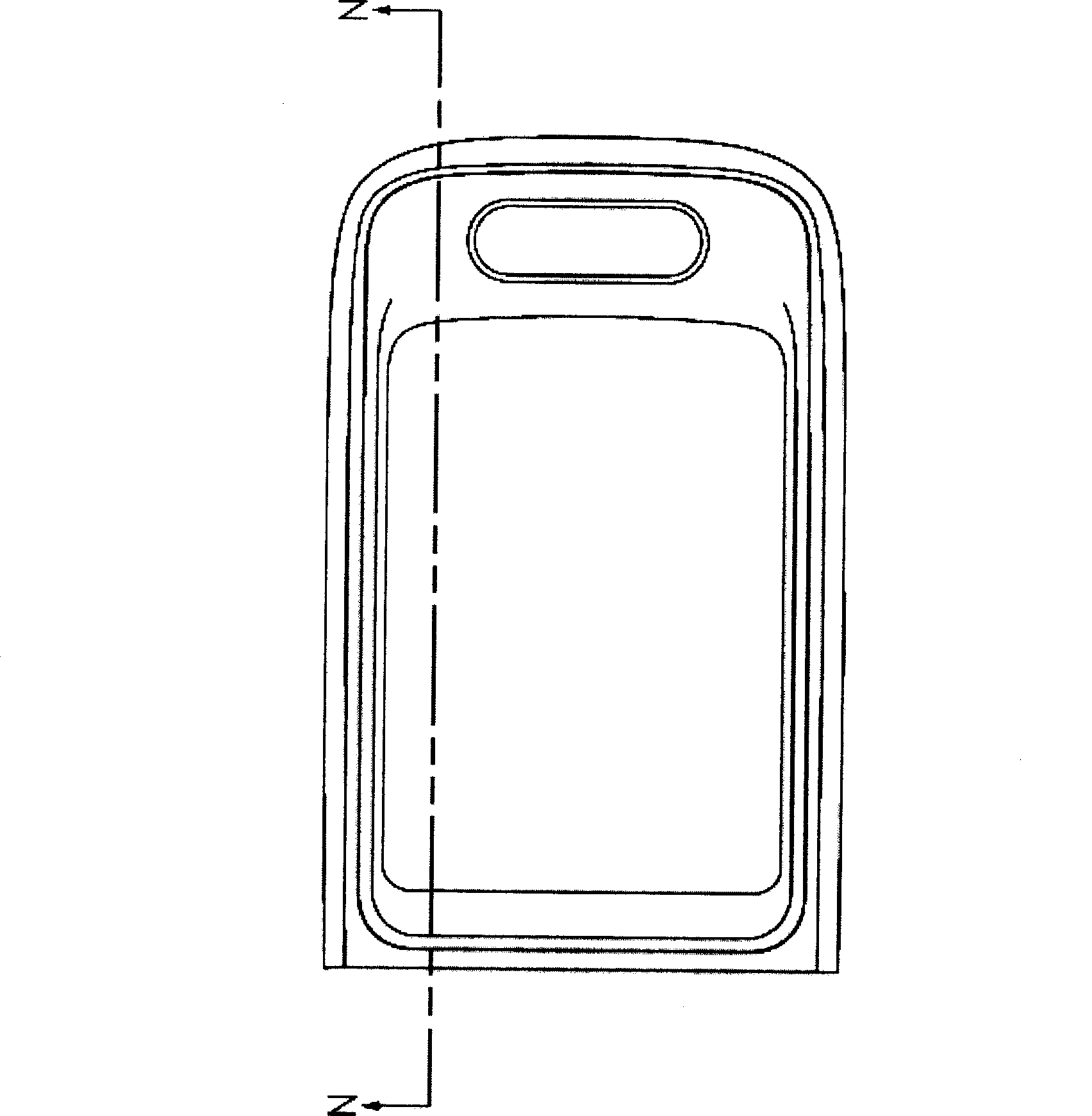

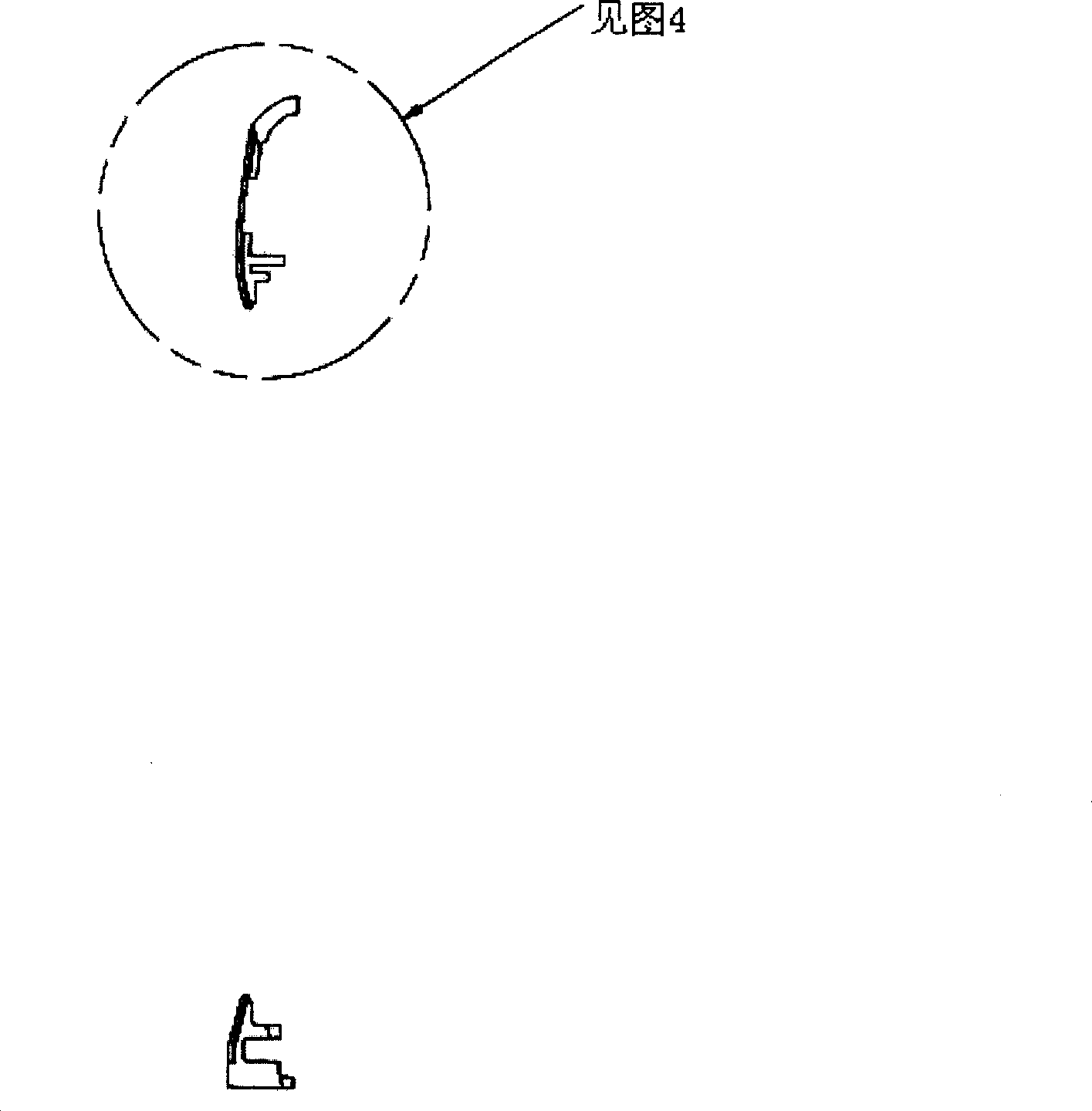

[0011] The method of the present invention first designs a perforation in the area where the non-metallic shell of the electronic product will cover and the appearance of the metal parts, and after the metal parts and the non-metallic shell are assembled, apply a quick-drying conductive glue to the opening. , make sure the glue is in contact with the metal and "ground". After the conductive glue dries and hardens, the metal and the "ground" are firmly connected through the conductive glue to achieve the purpose of grounding. The method of the invention is especially suitable for the electronic products with a plastic casing between the appearance metal part and the ground wire.

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] In this specific embodiment, the method of the present invention is applied to a mobile phone. as the picture shows: figure 1 It is an assembly and exploded ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap