Nonflammable mixed refrigerants (MR) for use with very low temperature throttle-cycle refrigeration systems

A low-temperature refrigeration system and refrigeration system technology, applied in 04] to provide a temperature lower than 223, respectively forming the first and second expansion airflow, 501 field, can solve the problem of complex requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

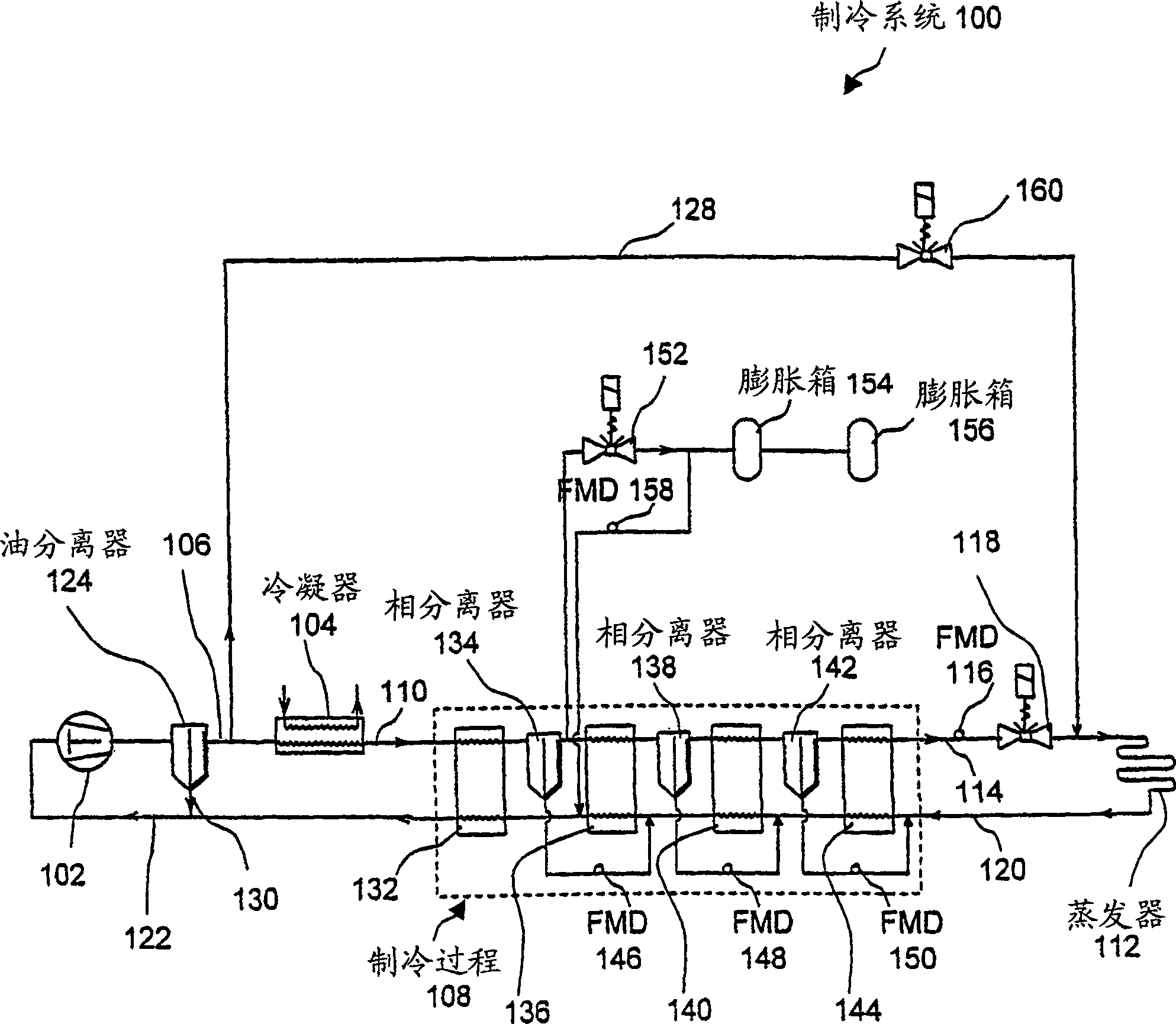

[0068] In the first embodiment, figure 1Shown is a deep cryogenic refrigeration system 100 employing the mixed refrigerants of the present invention. Refrigeration system 100 is a deep cryogenic refrigeration system comprising: a compressor 102 connected to an optional oil separator 124 connected to the condenser via a discharge line 106 104 on. A second outlet of oil separator 124 is connected back to compressor suction line 122 via oil return line 130 at the junction between refrigeration process 108 and compressor 102 . Condenser 104 is connected to the supply inlet of refrigeration process 108 via liquid line 110 . The supply inlet of refrigeration process 108 is connected to the inlet of evaporator 112 via refrigerant supply line 114 . In the refrigerant supply line 114 between the refrigeration process 108 and the evaporator 112 there is a flow modulating device (FMD) 116 which in turn is connected to a solenoid valve 118 . The outlet of the evaporator 112 is in tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com