Heat pump air conditioning system and its control method

A heat pump air conditioner and control method technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reduced energy efficiency of air conditioning systems, shortened running time of high energy efficiency in heating conditions, and reduced working performance of air conditioning systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

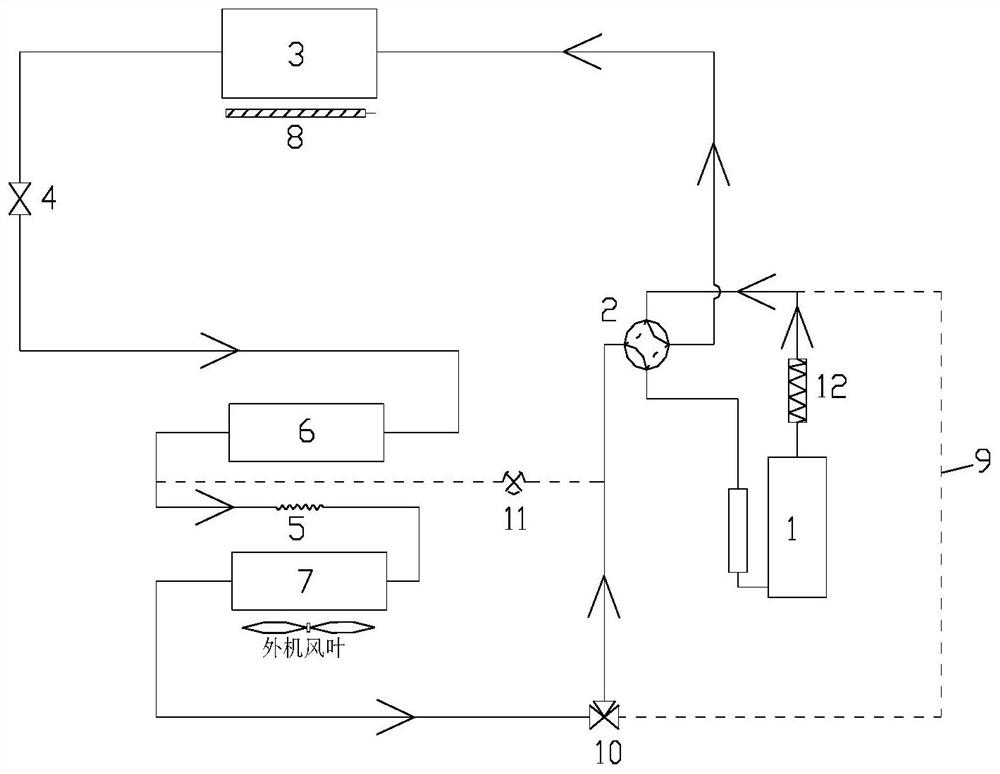

[0056] The first embodiment: the system cycle of the heat pump air conditioner of the present invention during the heating period is as follows figure 1 As shown, the refrigerant heating device is installed on the compressor discharge port pipeline. After the refrigerant comes out of the compressor discharge port, it passes through the refrigerant heating device, then enters the internal heat exchanger, and enters the first section after passing through the internal heat exchanger. Flow device 4, the throttled refrigerant first enters the heat exchanger 1 of the external unit to exchange heat with the outside air, and the refrigerant after heat exchange is throttled by the second throttling device 5 and then enters the heat exchanger 2 of the external machine, Finally, it returns to the suction port of the compressor through the three-way valve and the four-way valve to complete a heating cycle of the refrigerant. Since the refrigerant coming out of the heat exchanger 1 of the...

no. 2 example

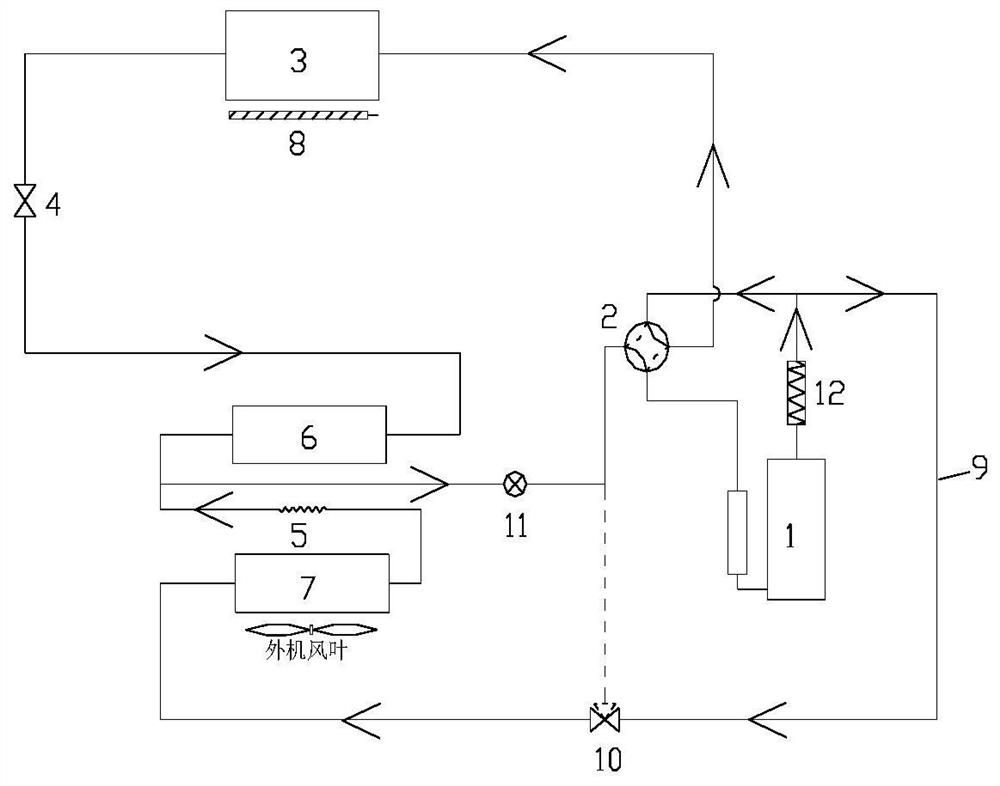

[0081] The second embodiment: the second embodiment of the present invention is to arrange the refrigerant heating device of the first embodiment on the circuit of the suction port of the compressor. In low temperature conditions, when the heat pump air conditioner is heating and heating, the refrigerant heating device is turned on through the control of the system to increase the compressor suction temperature and discharge temperature, so as to inhibit frosting and prolong the heating time. Thermal system cycle as image 3 shown. During the defrosting period, when the heat pump air conditioner is running, turn on the refrigerant heating device to increase the compressor suction temperature and discharge temperature. The high-temperature gas can speed up the defrosting speed of the outdoor unit. During the defrosting period, the system cycle is the same as the scheme 1. There are two defrosting methods ,Such as Figure 4 shown.

no. 3 example

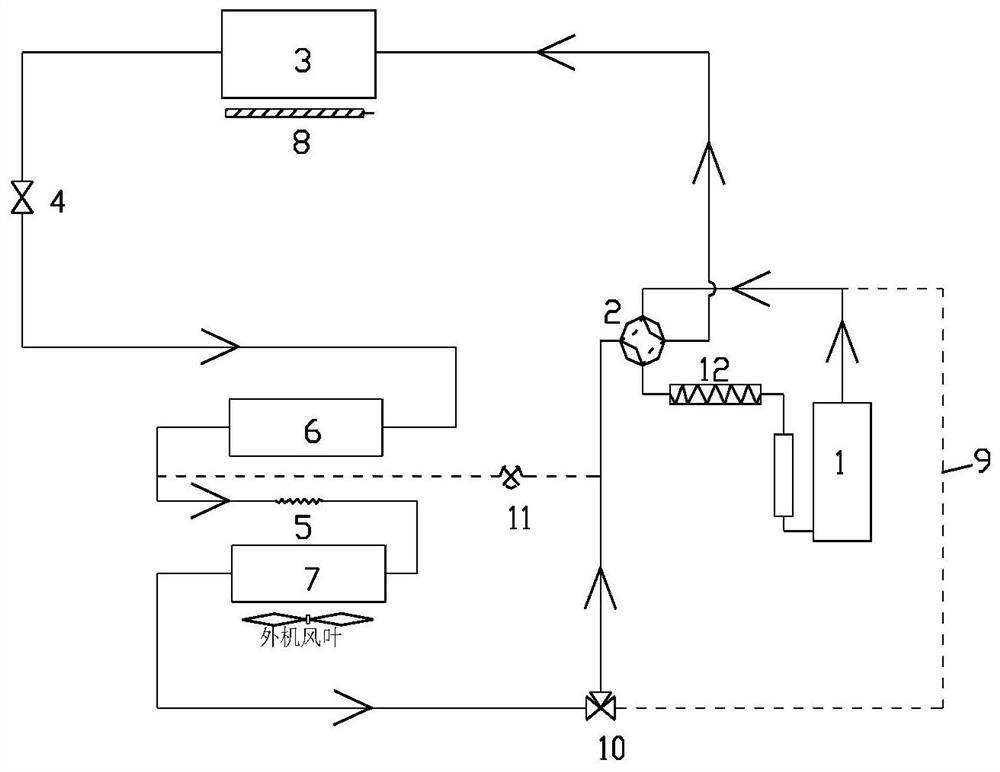

[0082] The third embodiment: the third embodiment of the present invention is that the refrigerant heating device of the first embodiment is arranged on the pipeline between the external unit heat exchanger 2 (ie, the defrosting heat exchanger 7 ) and the three-way valve. In low temperature conditions, when the heat pump air conditioner is heating and heating, through the control of the system, the refrigerant heating device is turned on to increase the compressor suction temperature and discharge temperature, so as to inhibit frosting and prolong the heating time. The system cycle like Figure 7 shown. When the heat pump air conditioner is running during the defrosting period, the refrigerant coming out of the compressor is heated by the refrigerant heating device and then passes through the heat exchanger 2 of the outdoor unit. performance, the system circulation during defrosting is the same as that of scheme 1, and there are two defrosting methods, such as Figure 6 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com