Novel dental zirconium oxide prosthesis and its preparing process

A zirconia and restoration technology, applied in the field of dental colored zirconia restoration materials and their preparation, can solve the problems of few researches on colored zirconia restorations and insufficient strength, and achieve the goal of controlling production costs and product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of Nano Y by Chemical Co-precipitation 2 o 3 -CeO 2 -ZrO 2 Powder

[0027] Take 3mol Y(NO 3 ) 3 ·5H 2 O, 3molCe(NO 3 ) 3 ·6H 2 O and 95.5mol ZrOCl 2 ·8H 2 O is dissolved in water and mixed, a small amount of polyethylene glycol is added to the mixed liquid as a dispersant, and excess ammonia water is added to precipitate, and the pH value is controlled to be greater than or equal to 10, and the colloidal precipitate is washed with deionized water to remove chloride ions (using AgNO 3 Instructions), disperse by ultrasonic wave for 10 minutes. After the precipitate was dried at 110°C, it was calcined at 800°C for 1 hour, then ground and spray-dried to obtain Y-Ce-TZP powder, wherein Y 2 o 3 : CeO 2 : ZrO 2 The molar ratio is 1.5:3:95.5. Use the same method to get the corresponding amount of Y (NO 3 ) 3 ·5H 2 O, Ce(NO 3 ) 3 ·6H 2 O and ZrOCl 2 ·8H 2 O can produce other Y-Ce-TZP powders, where Y 2 o 3 : CeO 2 : ZrO 2 The mol...

Embodiment 2

[0028] Example 2 Manufacture of dental articles

example 1

[0030] With 871.71g the nanometer (1.5mol% Y 2 o 3 +3mol% CeO 2 +95.5mol% ZrO 2 )Y-Ce-TZP powder and 127.24g nanometer Al 2 o 3 (Hangzhou Dayang Nano Technology Co., Ltd.) and 0.97g coloring agent Bi 2 o 3 mixed, where Y 2 o 3 : CeO 2 : ZrO 2 :Al 2 o 3 : Bi 2 o 3 The molar ratio is 1.5:3:95.5:15:0.025. The above mixture was ball milled and mixed in deionized water containing 20% (volume) ethanol for 24 hours, then polyvinyl alcohol (PVA) was added to make the concentration of PVA reach 1% (volume), ball milled for 2 hours, and spray granulation was carried out at 200°C , to obtain 60-80μm particles, use this particle powder to form isostatic pressing under 200MPa pressure, then cut into blanks, put them in an electric furnace for initial sintering at 1050°C for 2h, and the heating and cooling speeds are both 2°C / min. Then sinter at 1500°C for 2h, and cut the sample into Φ10×1mm for L * 、a * , b * optical test.

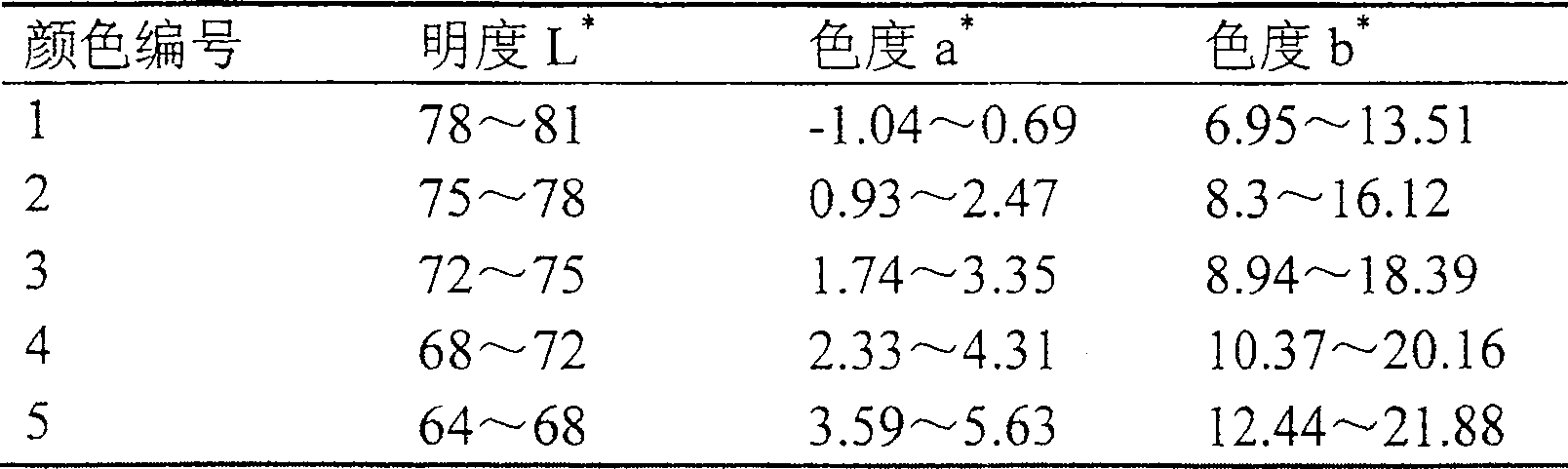

[0031] Result: naked eye color creamy yellow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com