Staple device

A technology for stapling books and staples, which is applied in the direction of nailing U-shaped nail tools, nailing tools, manufacturing tools, etc. It can solve the problems of difficult long-distance transportation, heavy load, and falling of nail boxes, and achieve good productivity. , Improve operability, and realize the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086]

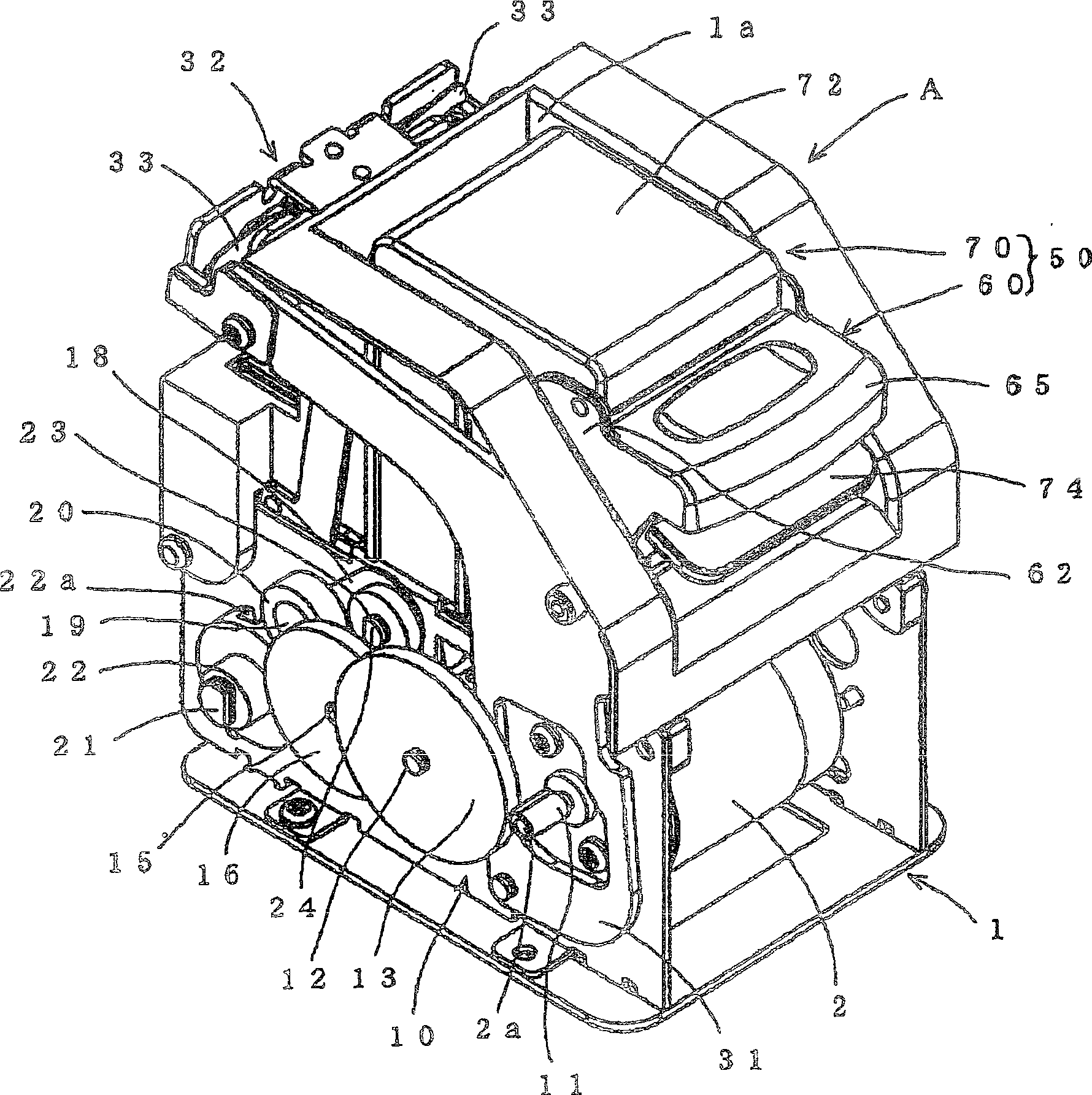

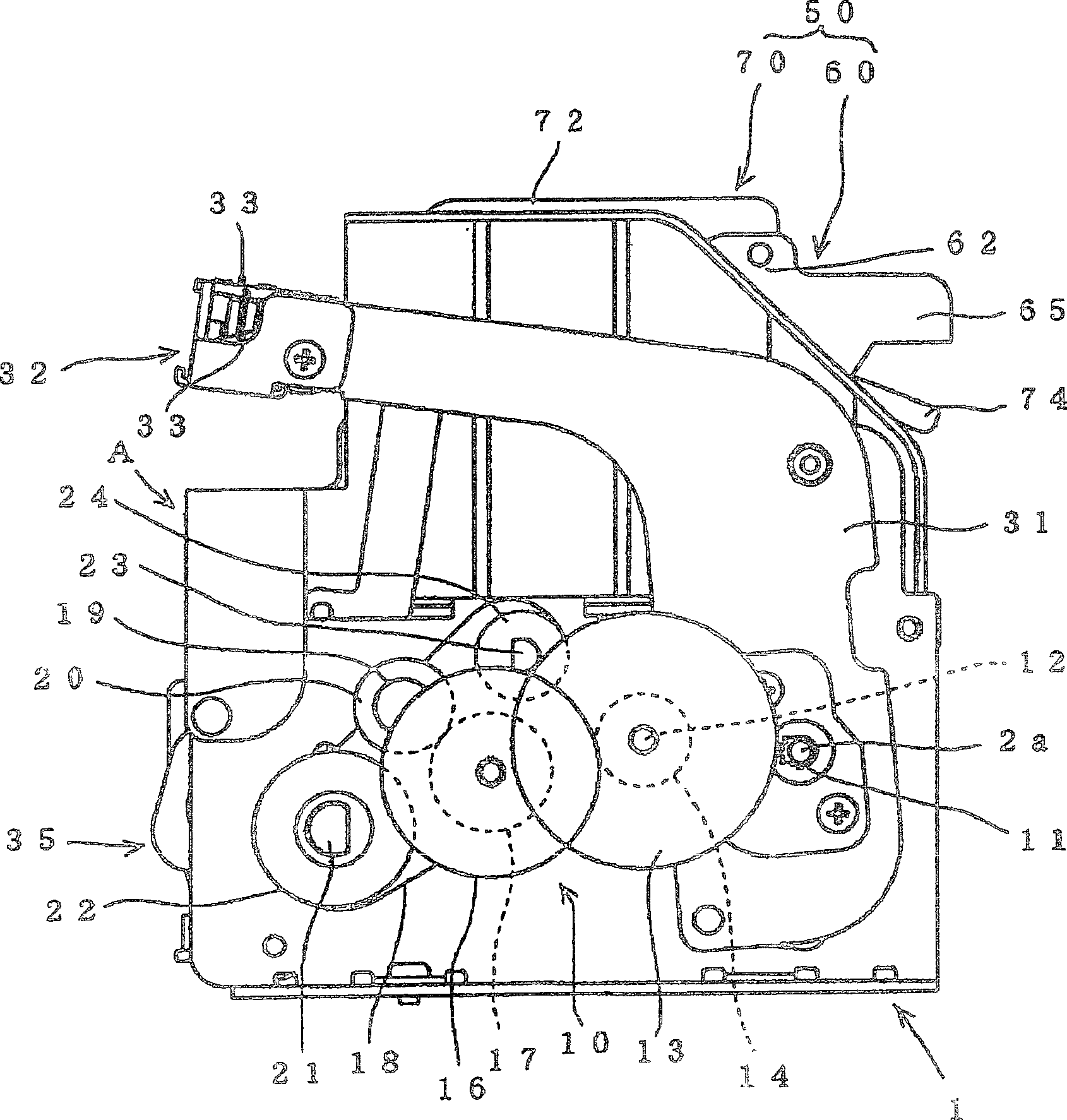

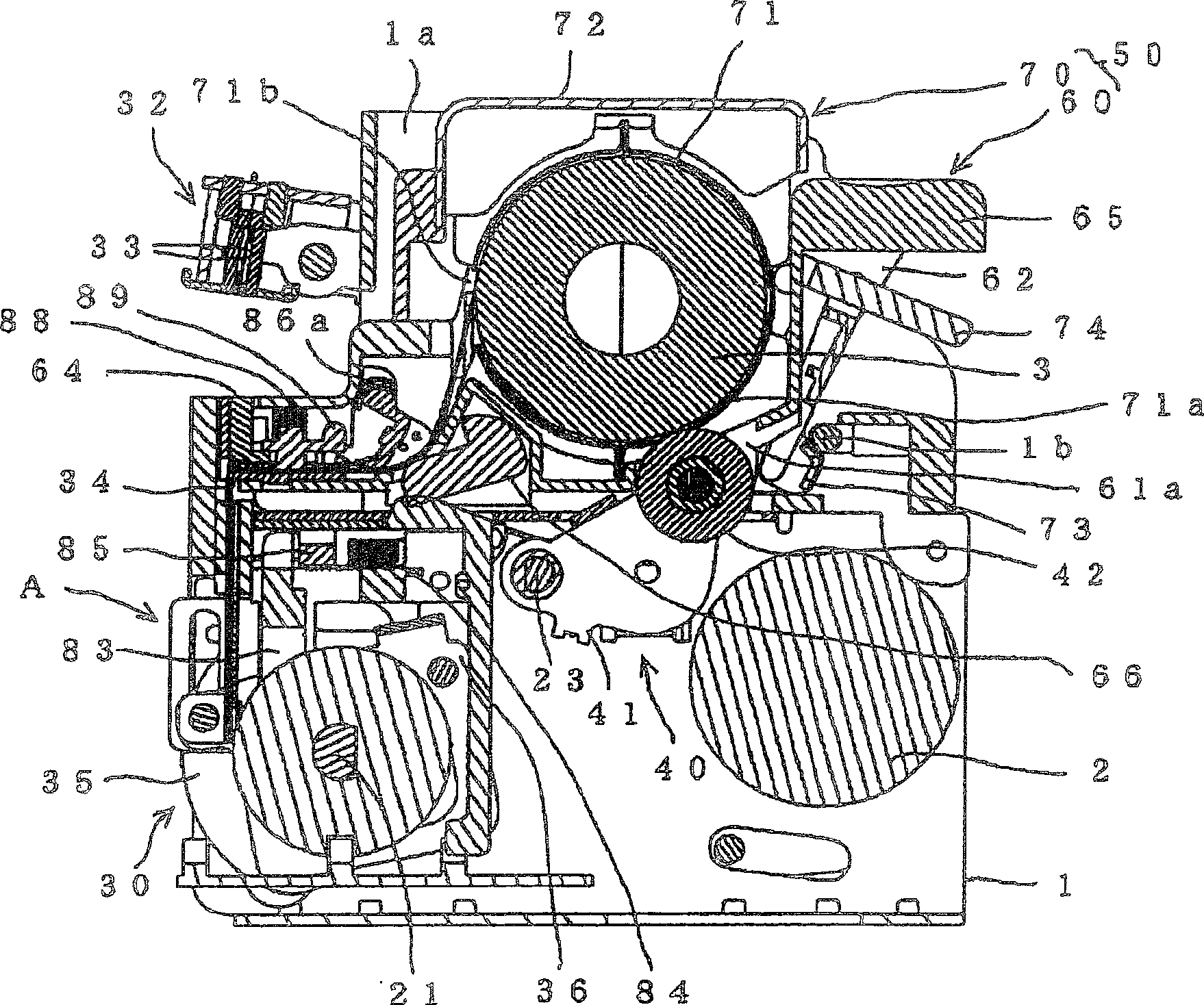

[0087] figure 1 It is a perspective view of the appearance of the stapling device according to the first embodiment of the present invention, figure 2 is a side view of the stapler, image 3 It is a longitudinal sectional view of the stapler.

[0088] exist Figure 1 ~ Figure 3 Among them, the stapler A has a main frame 1 mounted on an image forming apparatus (not shown) intended to include a post-processing apparatus such as a sorter or a finisher.

[0089] A forward and reverse drive motor 2 is fixed on the main frame 1 . In addition, the main frame 1 is equipped with: a power transmission gear part 10 for transmitting the rotational drive of the forward and reverse drive motor 2; The staple supply unit 40 that performs the staple supply operation when the forward and reverse drive motor 2 is reversed, and the staple cartridge 50 that can be attached to and detached from the main frame 1 .

[0090]

[0091] 4 shows the structure of the power transmission ...

Embodiment 2

[0136] Figure 17 It is a schematic diagram of an electric stapler (staple device) according to a second embodiment of the present invention. The electric stapler is composed of an electric stapler main body 101 and a staple cartridge 102 .

[0137] The electric stapler main body 101 has a drive link 104 that oscillates with an output shaft 103 of the motor, a forming plate 105 driven by a force transmitted from the output shaft 3 through an intermediate gear 103a, a drive plate 106, and the like. A clamp 107 is provided at the front end of the drive link 104 .

[0138] staple box 102, such as Figure 18 As shown in FIG. 1 , it includes: a storage unit 108 for storing a plurality of straight staples inside; and a driving unit 109 for driving out staples discharged from the lower end of the storage unit 108 . In addition, in the storage portion 108, a plate-shaped staple (not shown) that connects a plurality of straight staples in a plate shape is stored in a stacked state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com