Engine crankshaft dynamic analysis method

A technology of dynamic analysis and analysis method, applied in the field of engine crankshaft dynamic analysis, can solve problems such as lengthening development cycle and increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

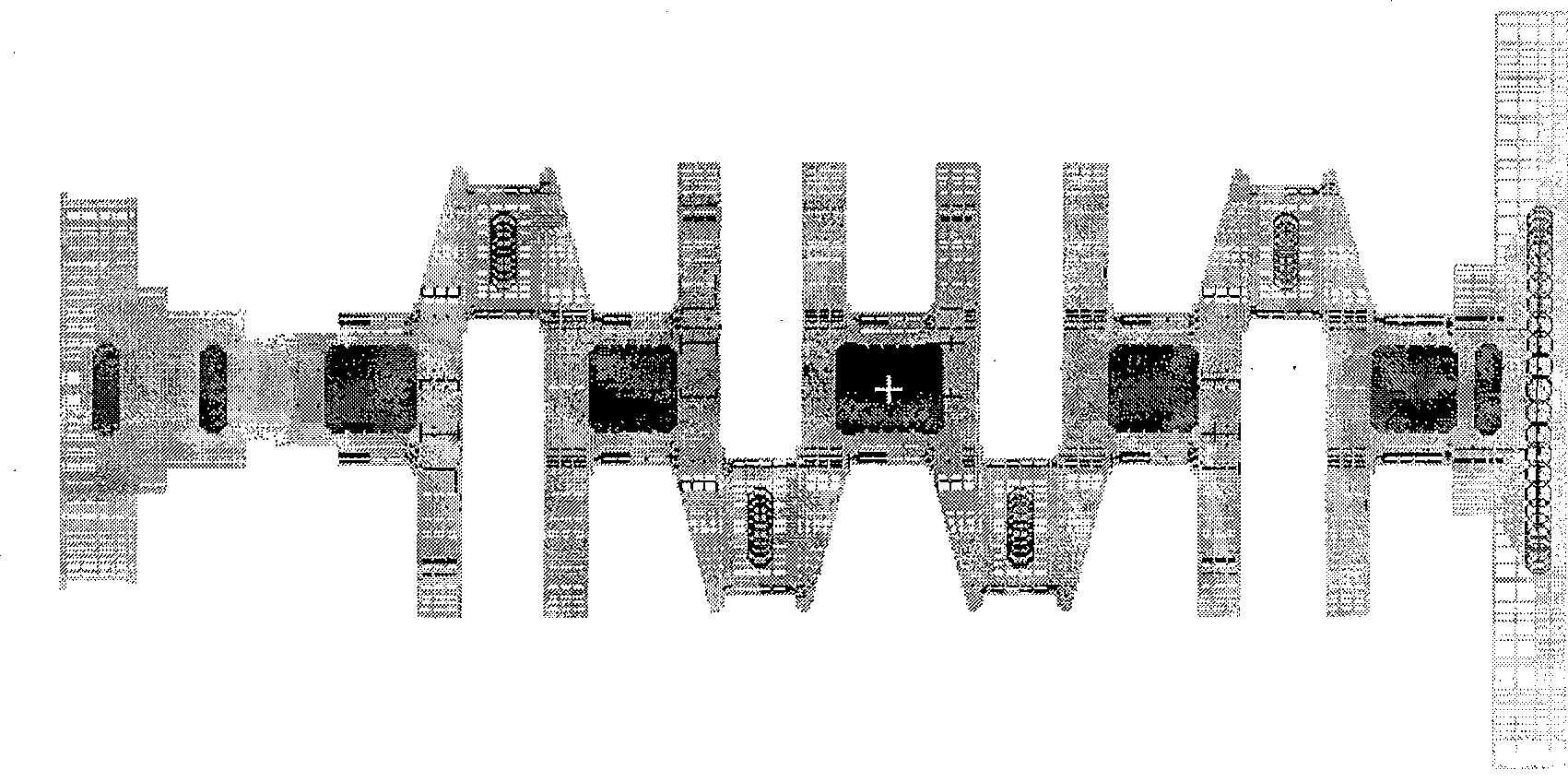

[0021] The analysis method of the present application will be further described in conjunction with the accompanying drawings.

[0022] 1. Mesh division:

[0023] 1.1 Mesh division of crankshaft system

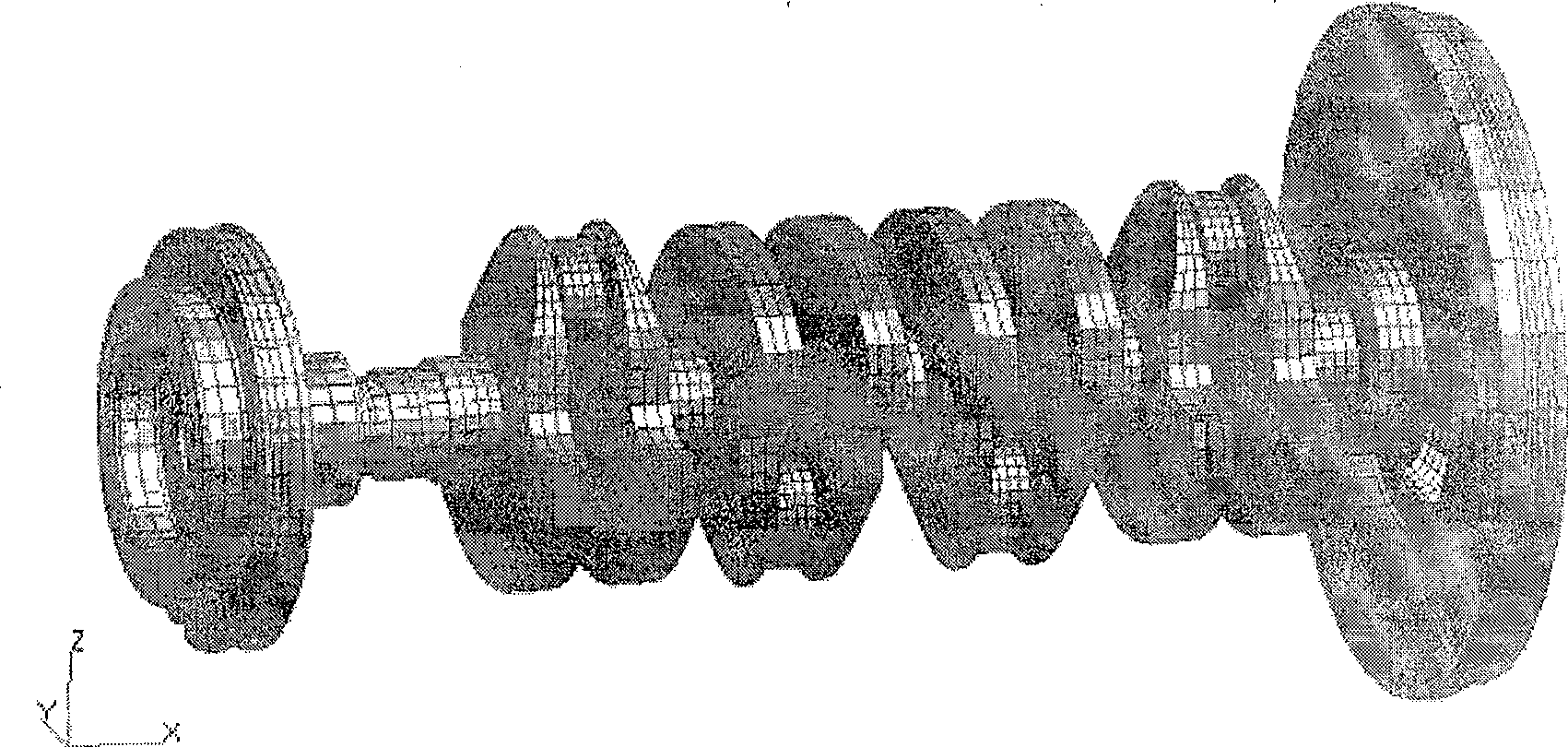

[0024] When meshing the crankshaft system, in order to ensure the smooth progress of the dynamic analysis of the crankshaft system and high calculation accuracy, it is necessary to ensure that there is sufficient mesh accuracy at the fillet, such as figure 1 shown. Due to the large model of the crankshaft system and many calculation conditions, the calculation of the crankshaft system adopts the substructure analysis method, that is, the modal compression method.

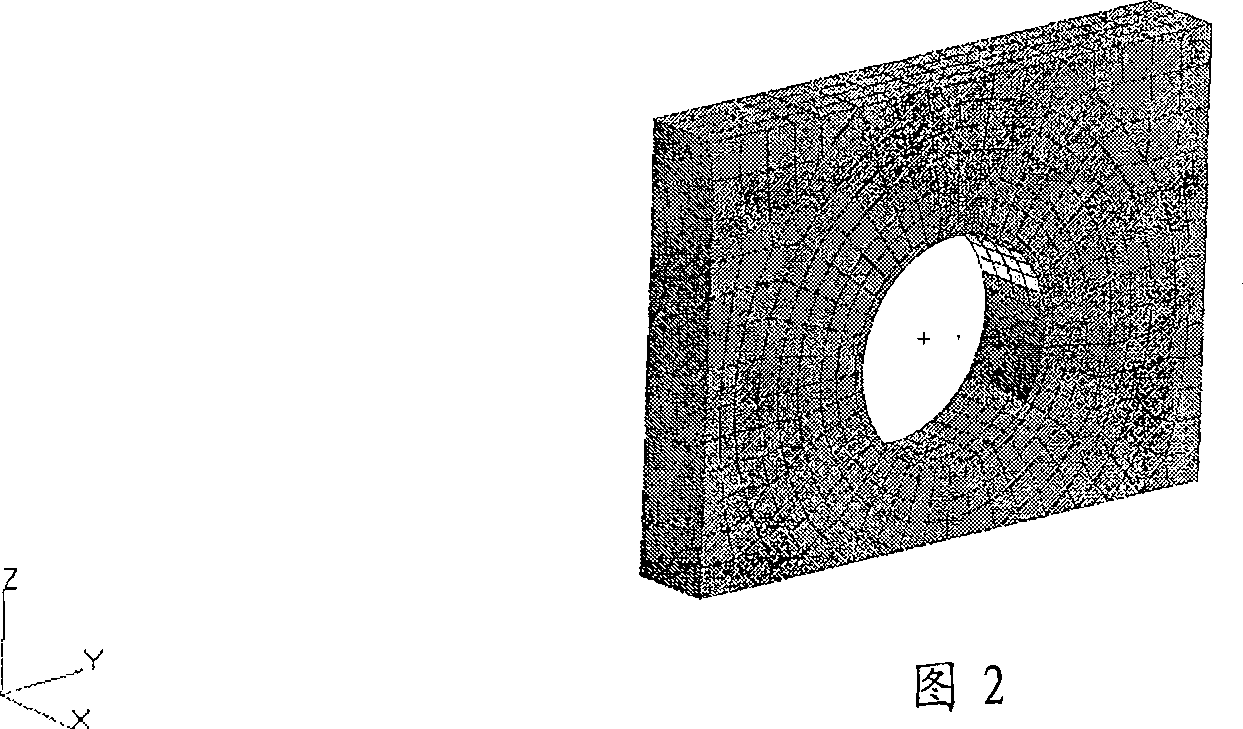

[0025] 1.2 Simple finite element model of main bearing wall

[0026] The simple main bearing wall FE model adopts hexahedral mesh, and the number of unit layers in the main bearing wall hole is required to be the same as that on the crankshaft main journal, which must be equally divided and equally spaced. as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com