Vehicle brace bar

A vehicle, contour technology, applied in the direction of vehicle components, axles, wheels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

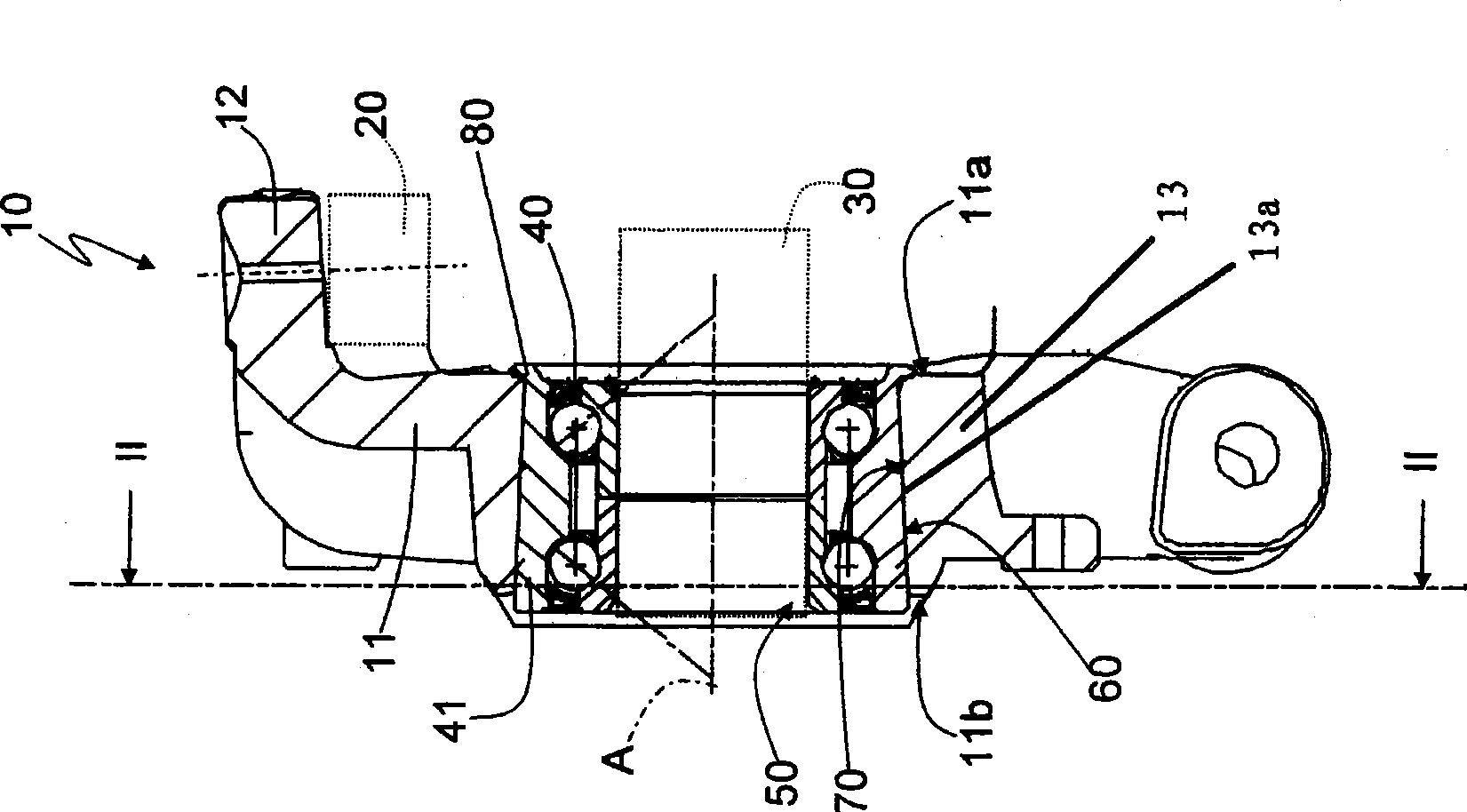

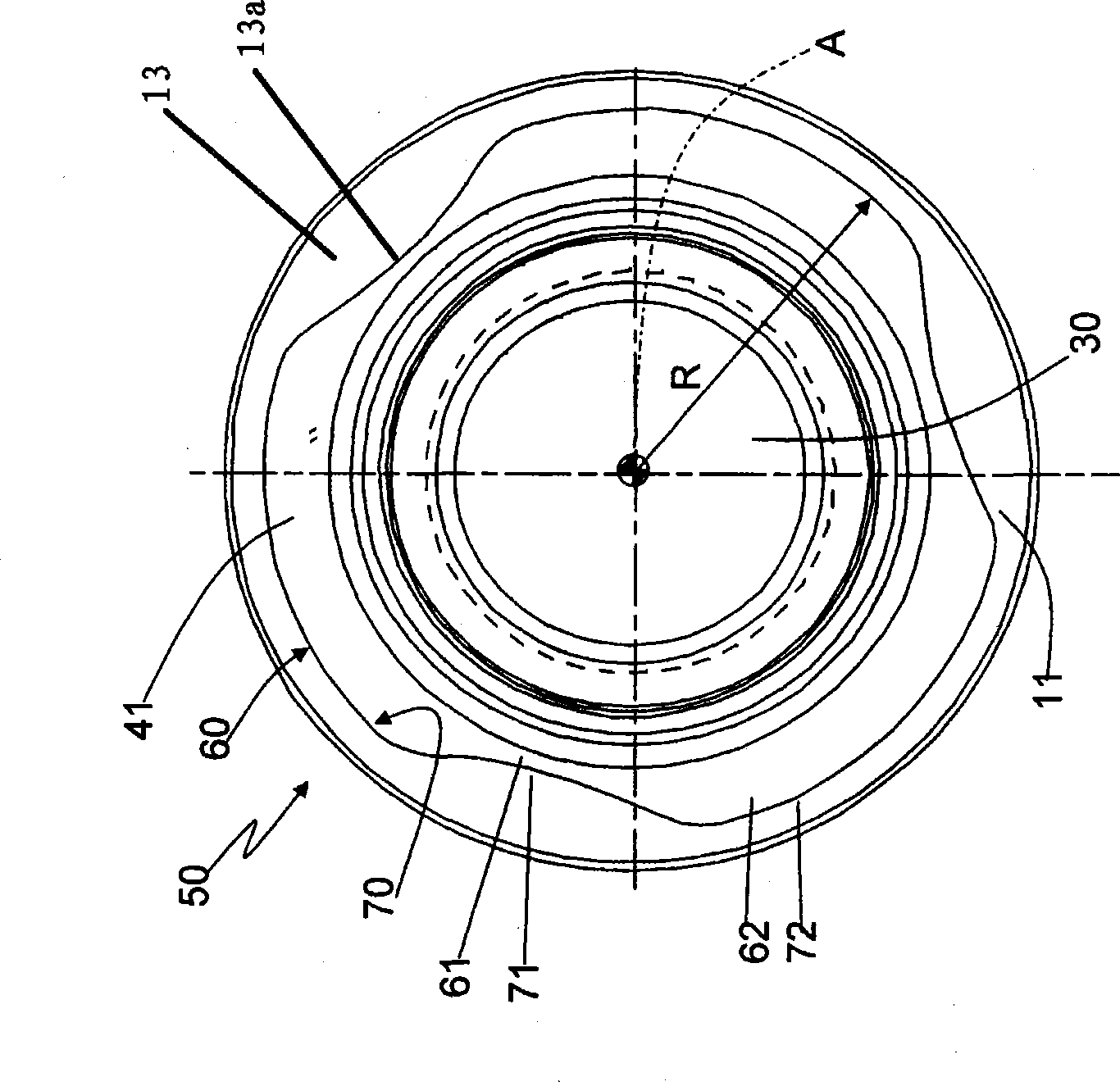

[0009] refer to figure 1 , The reference numeral 10 represents the whole vehicle strut.

[0010] The strut 10 is adapted to be placed between a suspension, shown schematically and referenced 20 , and a half shaft, shown schematically and referenced 30 .

[0011] The strut 10 comprises a central body 11, a connecting arm 12 for connection with the suspension 20, and a through housing 13 formed through the central body 11 along a longitudinal axis for accommodating a Rolling contact bearing 40 between strut 10 and half shaft 30 .

[0012] The arm 12 extends from the side surface 11a of the central body 11 itself in a direction substantially transverse to the central body 11 and through the housing 13 on one side through the surface 11a itself and on the other side substantially parallel to the surface 11 and transverse to the The surface 11b of the axis A is axially defined.

[0013] Finally, the strut 10 includes a joint device 50, which is placed between the bearing 40 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com