Heavenly body sensor measuring reference transform method and apparatus thereof

A technology of celestial body sensor and measurement datum, applied in the direction of combined navigator, etc., can solve the problems of difficult processing, complicated installation process, difficult high-precision positioning, etc., and achieve the effect of convenient operation and simple processing and installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below in conjunction with the accompanying drawings.

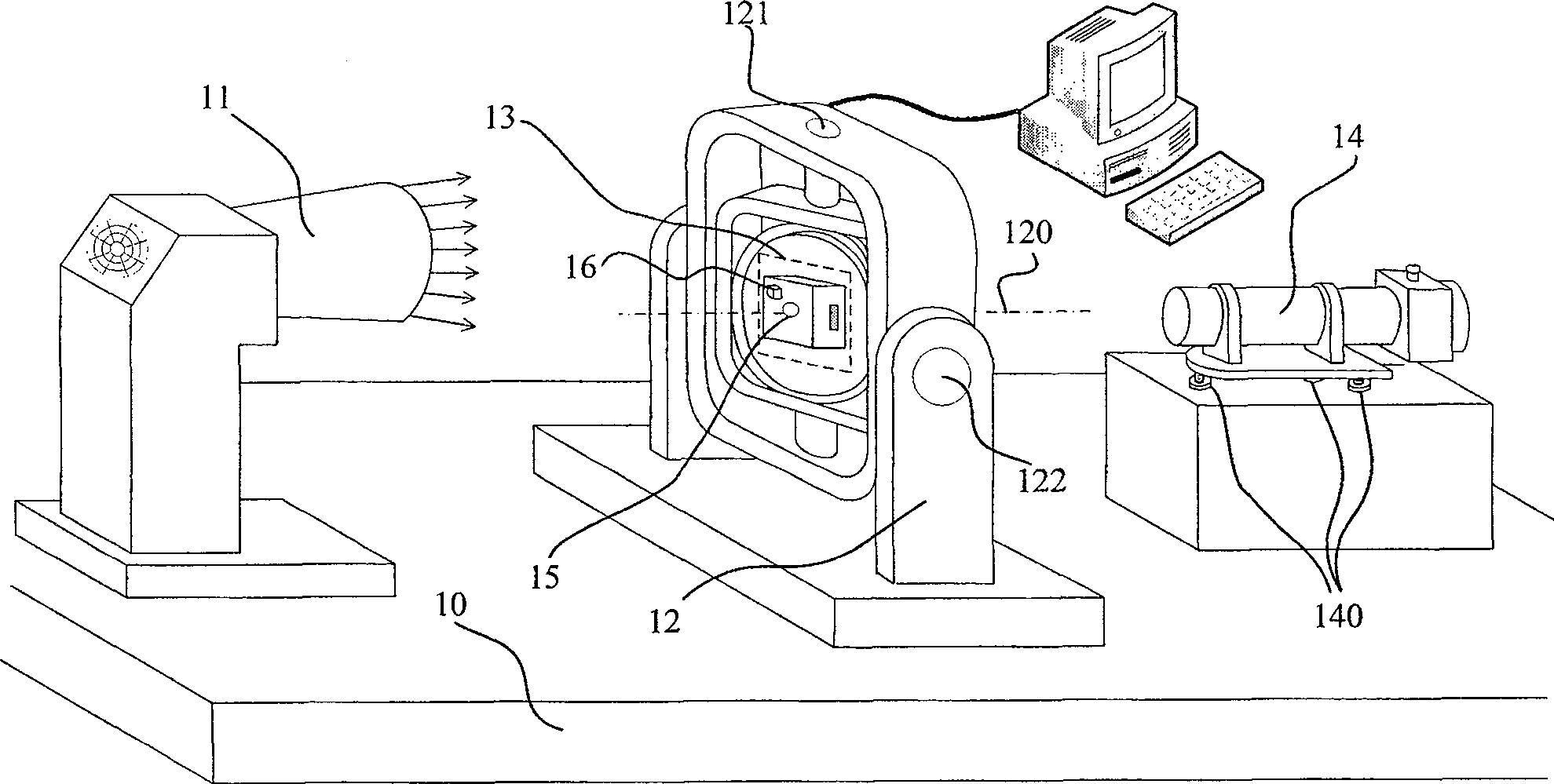

[0025] figure 1 It is a structural schematic diagram of the conversion device of the present invention, such as figure 1 As shown, the conversion device of the present invention includes an optical platform 10, a light source simulator 11, a high-precision three-axis turntable 12, a plane mirror 13 and a photoelectric autocollimator 14, wherein the light source simulator 11, the high-precision three-axis turntable 12 and the photoelectric autocollimator 14 are erected on the optical table 10, and the astronomical sensor 15 equipped with the mirror cube 16 is fixedly arranged on the inner frame mounting surface of the three-axis turntable 12. The optical platform 10, the light source simulator 11, the high-precision three-axis turntable 12 and the photoelectric autocollimator 14 are all existing devices, the optical platform 10 adopts the WSZ-1 optical experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com