Device for testing integral performance of universal high speed processing tool system

A processing tool and system synthesis technology, applied in the field of mechanical engineering, can solve the problems of less research, lack of tool system, influence, etc., achieve high manufacturing precision and rigidity, save manufacturing cost, and stabilize measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

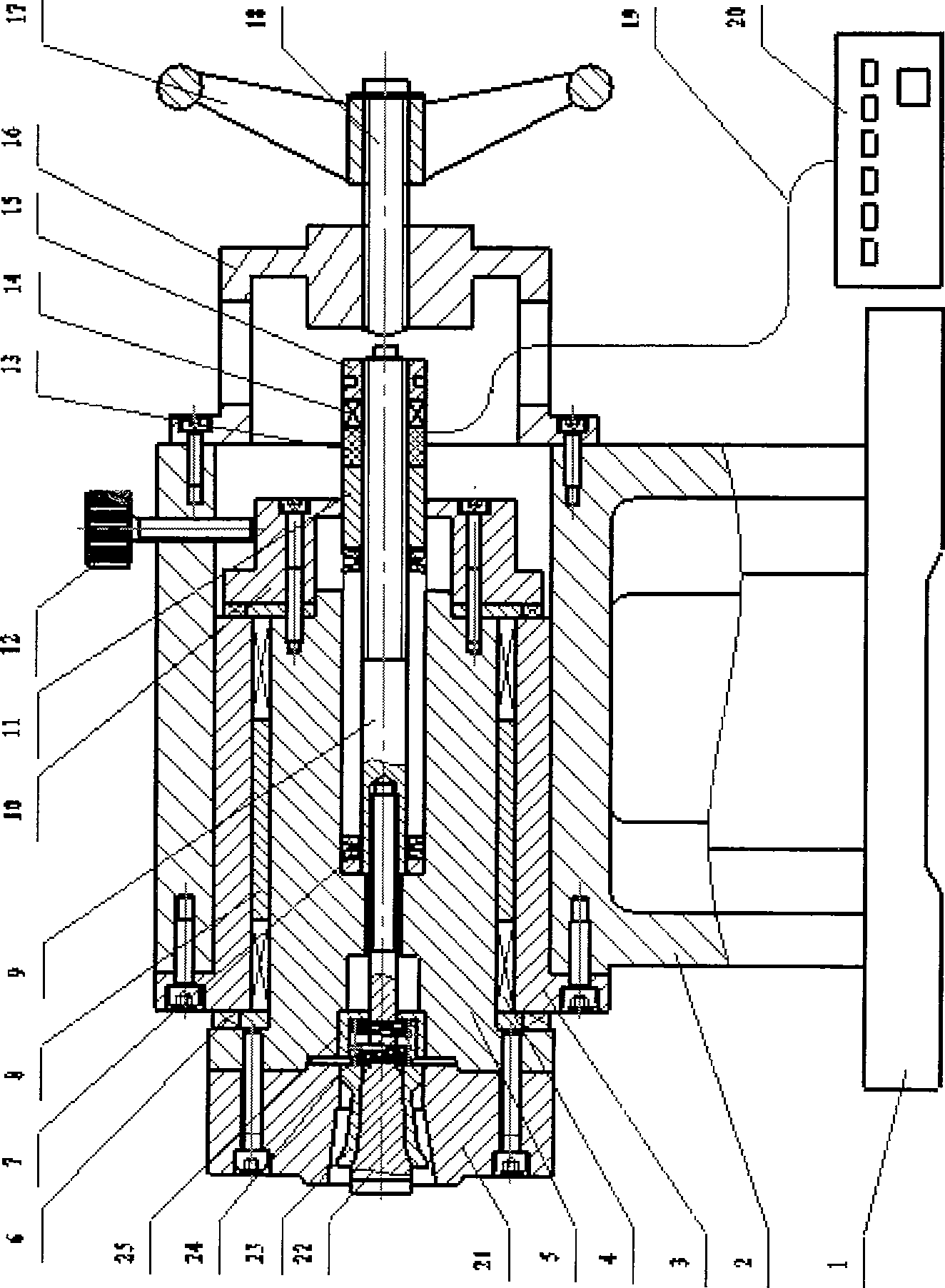

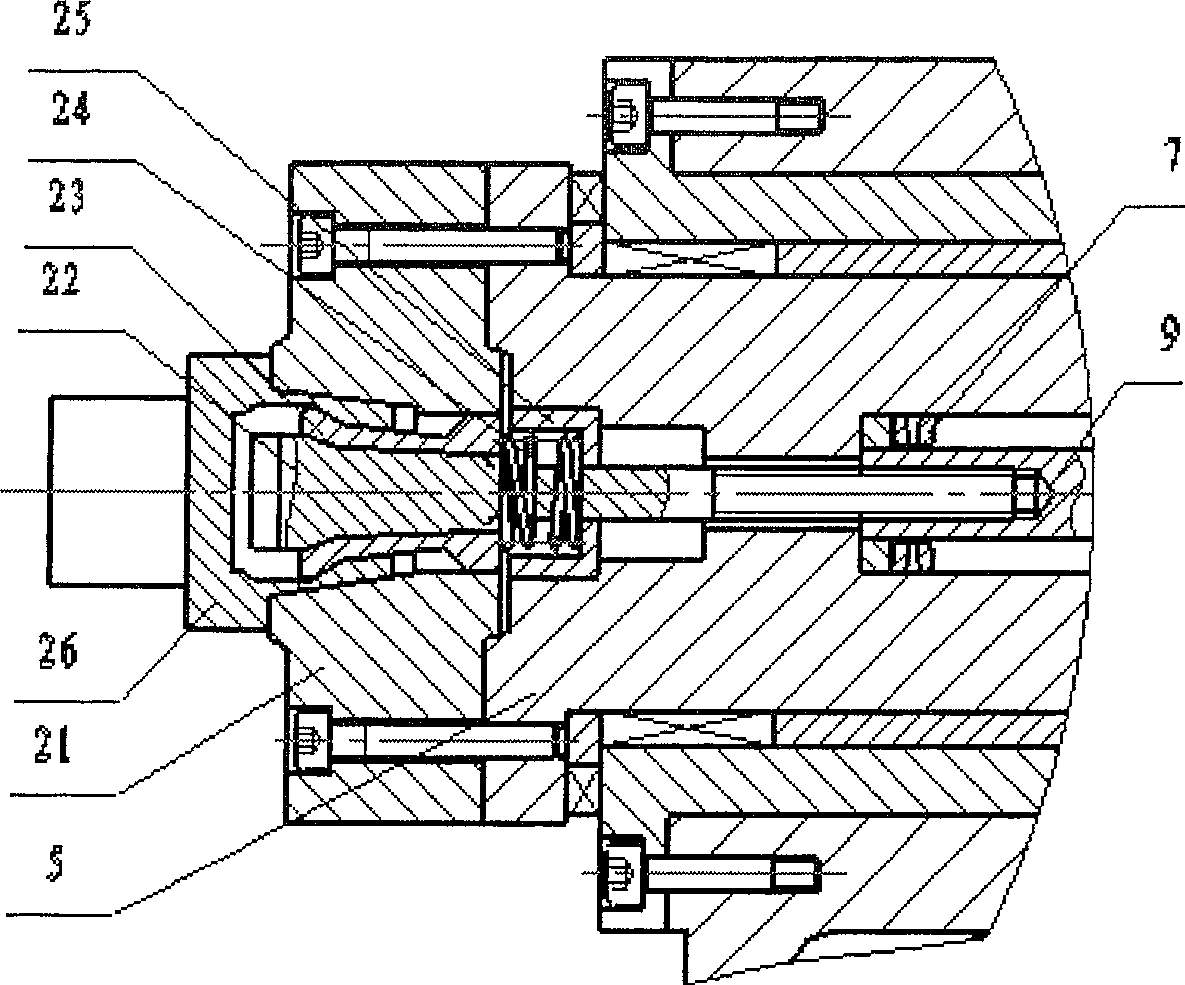

[0028] The present invention is a comprehensive performance testing device for a general high-speed machining tool system, which can be used to test and measure the various performances of different types of tool systems such as HSK, KM, BT and BIGULS; and can further study some main factors (clamping force, load, etc.) on the performance of these tool systems.

[0029] Such as figure 1, 2, 3, 4, 5, and 6, the test device of the present invention is composed of base 1, box body 2, spindle mechanism, pull rod 9, disc spring 7, sleeve 11, HSK handle clamping structure, KM tool holder clamping structure, BT and BIGULS tool holder clamping structure, tool handle loading and unloading mechanism, clamping force adjustment device, clamping force measuring device, and spindle locking device. Wherein: the box body 2 is fixed on the base 1 by bolts, and the contact surfaces of the base 1 and the box body 2 are scraped to ensure flatness. The main shaft mechanism is installed in the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com