Production process of vitamin A peanut oil

A production method and technology of peanut oil, which is applied in the field of edible oil, can solve the problems of low vitamin A content in peanut oil, lack of vitamin A, and impact on health, and achieve the effects of inhibiting light exposure, ensuring content, and preventing oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

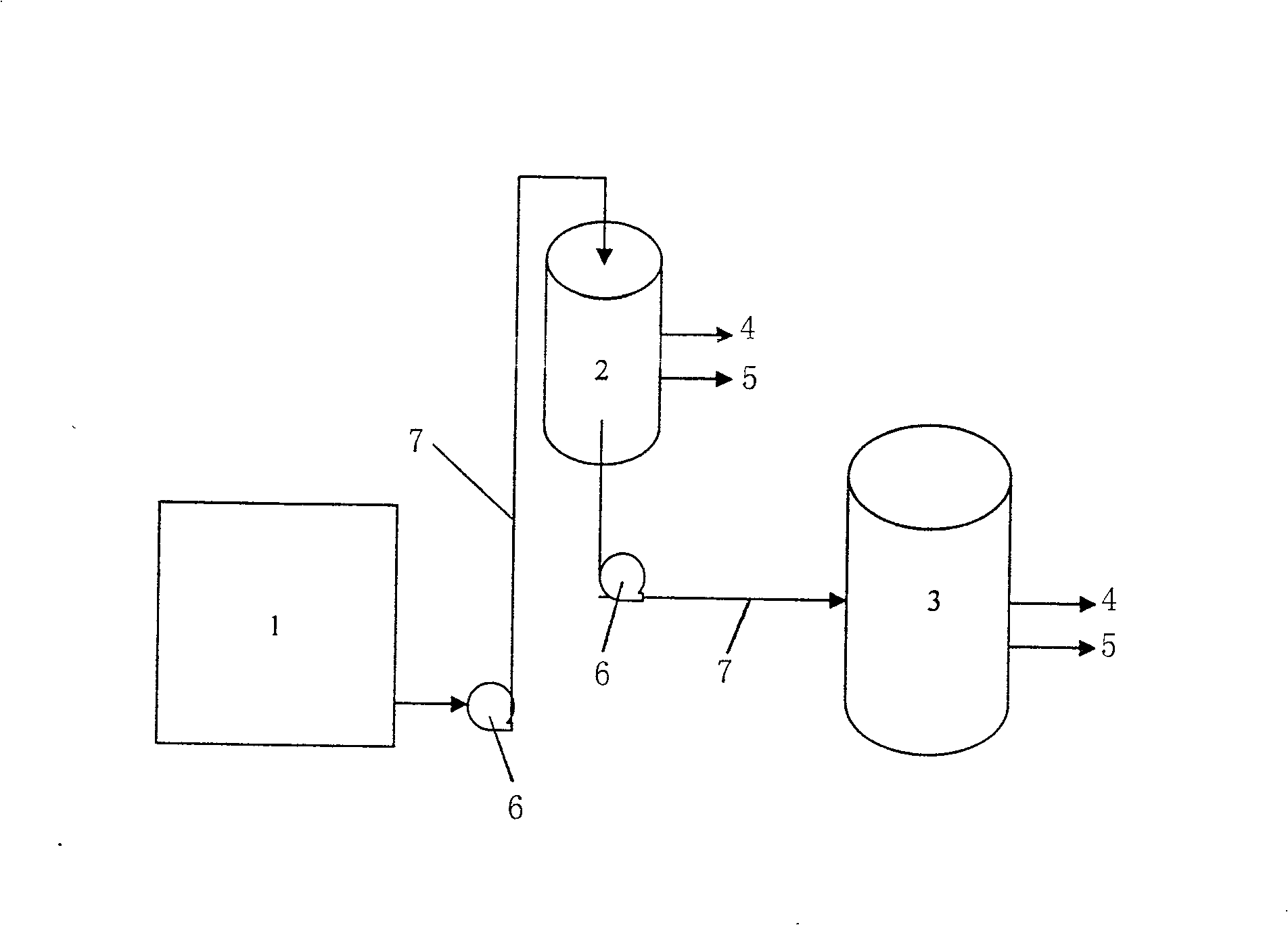

Image

Examples

Embodiment 1

[0013] Embodiment 1: the production method of vitamin A peanut oil, its process step is (A) carries out physical and chemical inspection to first-grade peanut oil, to reach GB1546-2003 standard, also comprises the following steps: (B) pumps first-grade peanut oil into first-order reaction In the tank, add vitamin A acetate with a weight ratio of 100000: 6.65, and carry out the primary reaction for 60 minutes at 40° C. at normal pressure and 30 rpm under stirring; (C) measure the pergasification value, acid value, The content of vitamin A, finish the primary reaction after being qualified; (D) the primary reaction oil of 1 part by weight is pumped into the secondary reaction tank, and then the primary peanut oil of 4 parts by weight is pumped into, and the reaction is carried out at normal pressure 40 ℃, 20 Carry out the secondary reaction for 60 minutes under rev / min stirring. During the reaction process, various physical and chemical indicators of the product are regularly det...

Embodiment 2

[0014] Embodiment two: the production method of dimension A peanut oil, its process step is (A) carries out physical and chemical inspection to first-grade peanut oil, to reach GB1546-2003 standard, also comprises the following steps: (B) pumps first-grade peanut oil into first-order reaction In the tank, add vitamin A acetate with a weight ratio of 100000: 13.30, and carry out a primary reaction for 80 minutes at 120° C. at normal pressure and 80 rpm under stirring; (C) measure the pergasification value, acid value, The content of vitamin A, finish the primary reaction after being qualified; (D) the primary reaction oil of 1 part by weight is pumped into the secondary reaction tank, and then the primary peanut oil of 4 parts by weight is pumped into, at normal pressure 120 ℃, 80 Carry out the secondary reaction for 120 minutes under rev / min stirring. During the reaction process, various physical and chemical indicators of the product are regularly detected, and the secondary r...

Embodiment 3

[0015] Embodiment three: the production method of dimension A peanut oil, its process step is (A) carries out physical and chemical inspection to first-grade peanut oil, to reach GB1546-2003 standard, also comprises the following steps: (B) pumps first-grade peanut oil into first-order reaction In the tank, add vitamin A acetate with a weight ratio of 100000:10.00, and carry out the primary reaction for 70 minutes under normal pressure, 80°C and 50 rpm stirring; (C) measure the pergasification value and acid value of the oil , the content of vitamin A, finish the primary reaction after being qualified; (D) pump the primary reaction oil of 1 part by weight into the secondary reaction tank, then pump the primary peanut oil of 4 parts by weight, at normal pressure, 80 ℃ , Under stirring at 30 rpm, carry out the secondary reaction for 90 minutes. During the reaction process, regularly detect various physical and chemical indicators of the product, and finish the secondary reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com