Rolling mill control device and method

A technology for control devices and rolling mills, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as the distance of rolling mills becoming longer and control lag, and achieve the effect of reducing influence and avoiding control lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. In order to facilitate understanding of the concept of the present invention, a reference example will be described first, and then the basic idea will be described.

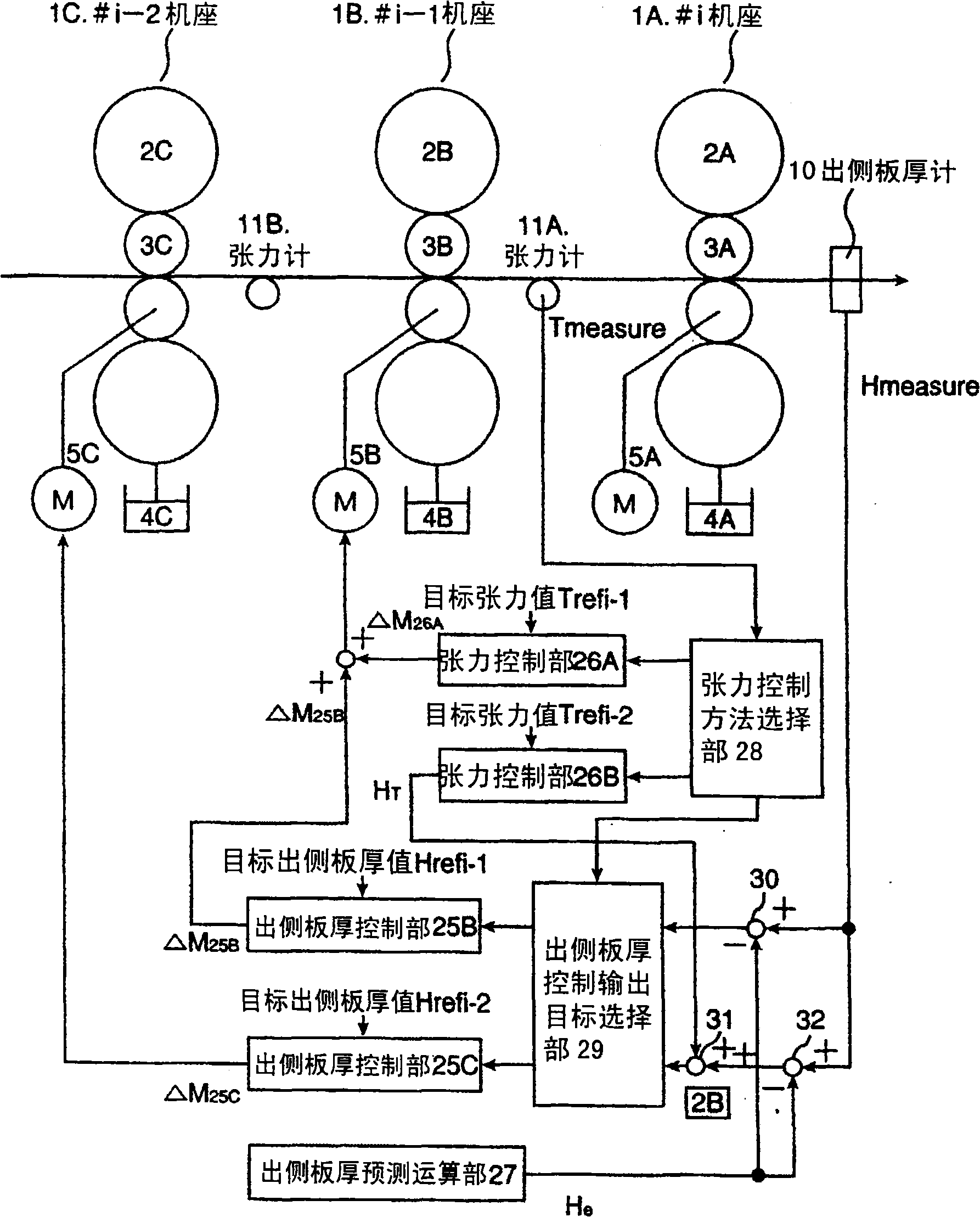

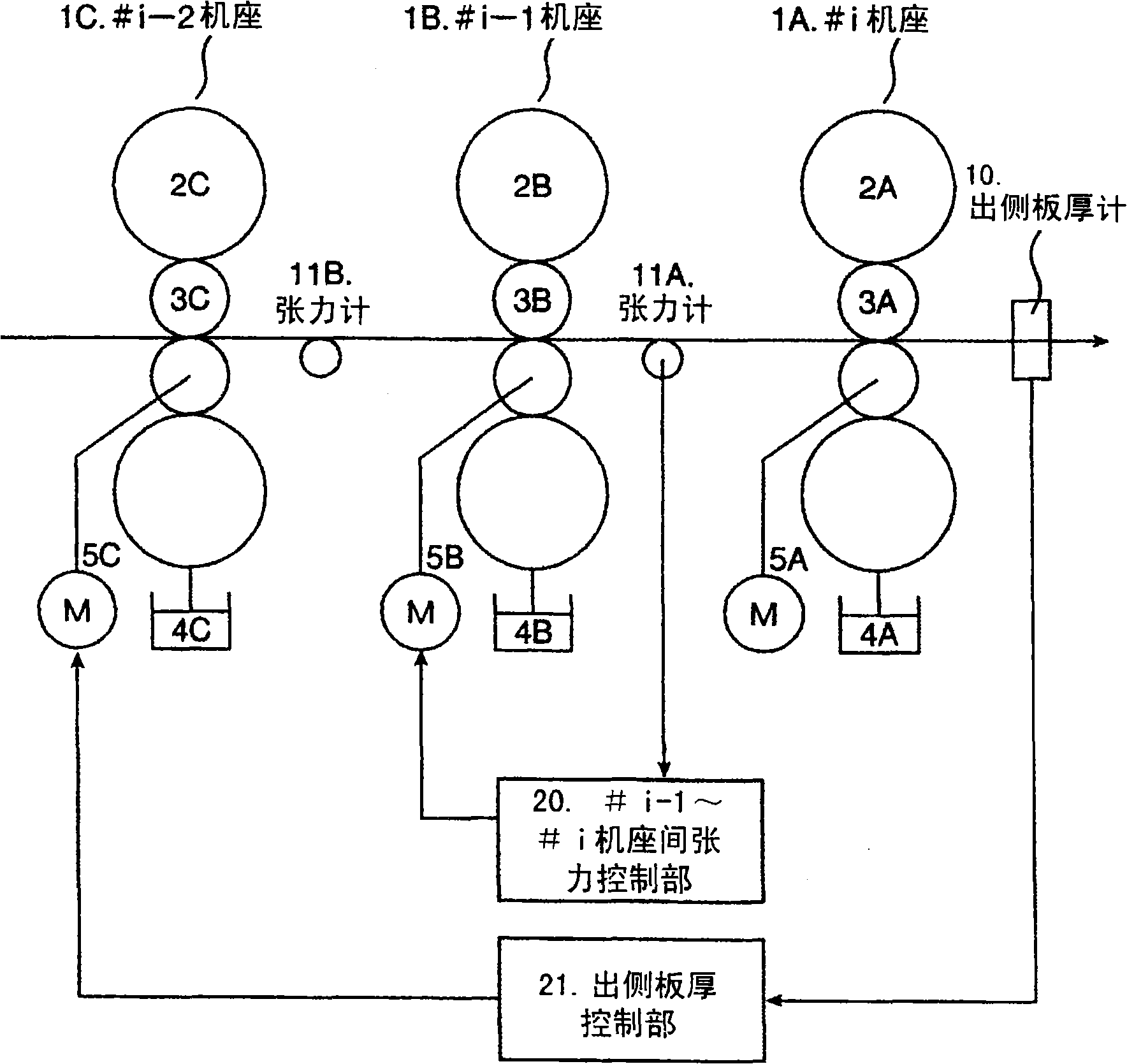

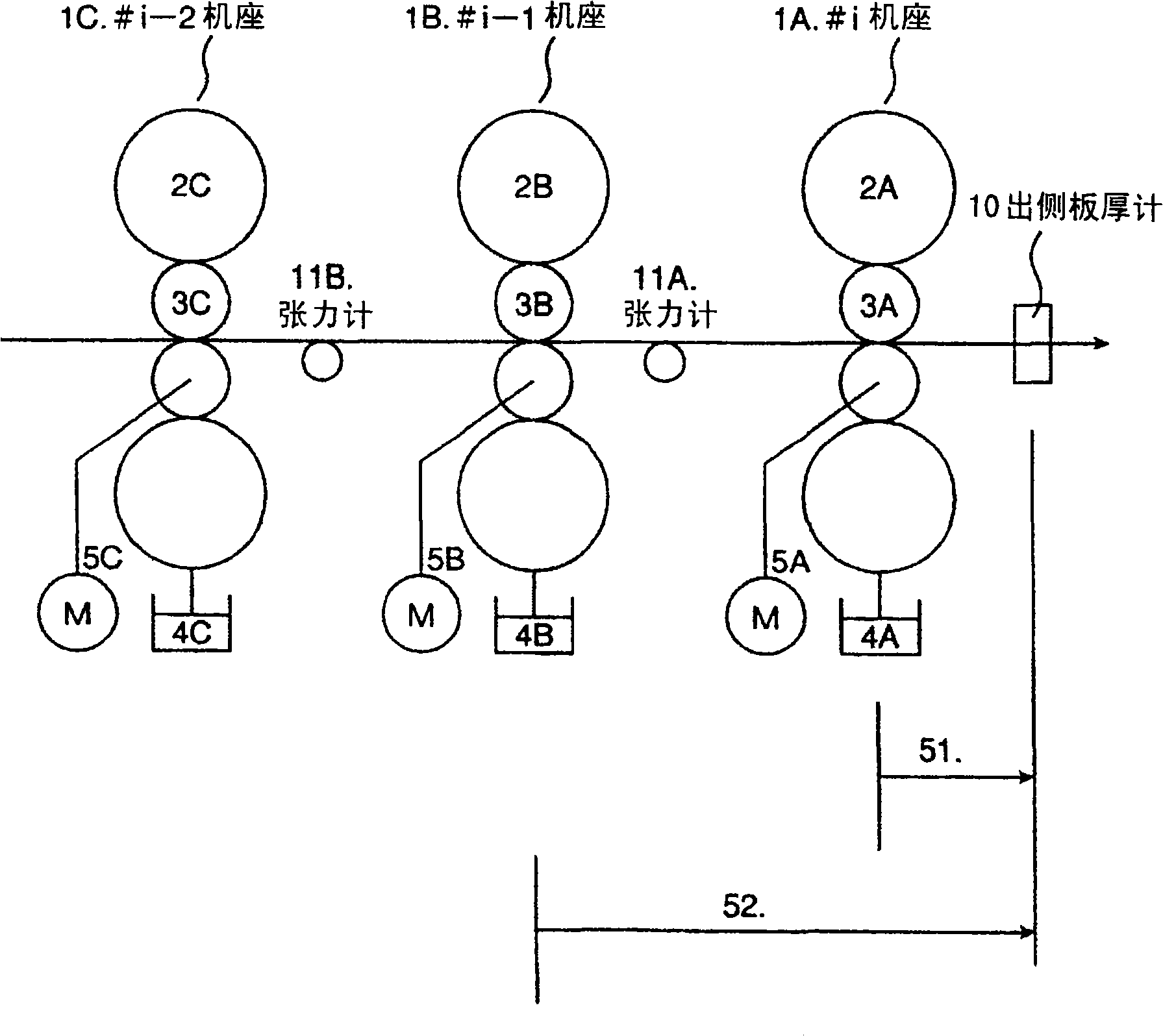

[0019] First, a reference example will be described. The plate thickness control and tension control of the tandem cold rolling mill using passivated rolls with high friction coefficient as the final stand are as follows: figure 2 structure shown. Each stand 1A (#i stand) to 1C (#i-2 stand) is composed of work rolls 3A, 3B, 3C and backup rolls 2A, 2B, 2C. In the tandem rolling mill composed of i-stands, the rolling mill has i-stands. Each stand is composed of the following: backup roll 2 (the general designation of symbols 2A, 2B, and 2C is denoted as symbol 2); work roll 3 (the general designation of symbols 3A, 3B, and 3C is denoted as symbol 3); and for controlling the work roll 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com