Electrical connector for printed circuit board

A connector and contact arm technology, applied in the direction of connection, circuit, connection of four or more poles, etc., can solve the problems of contamination of contact parts, tin absorption of flux or flux, etc., to achieve the effect of efficient manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

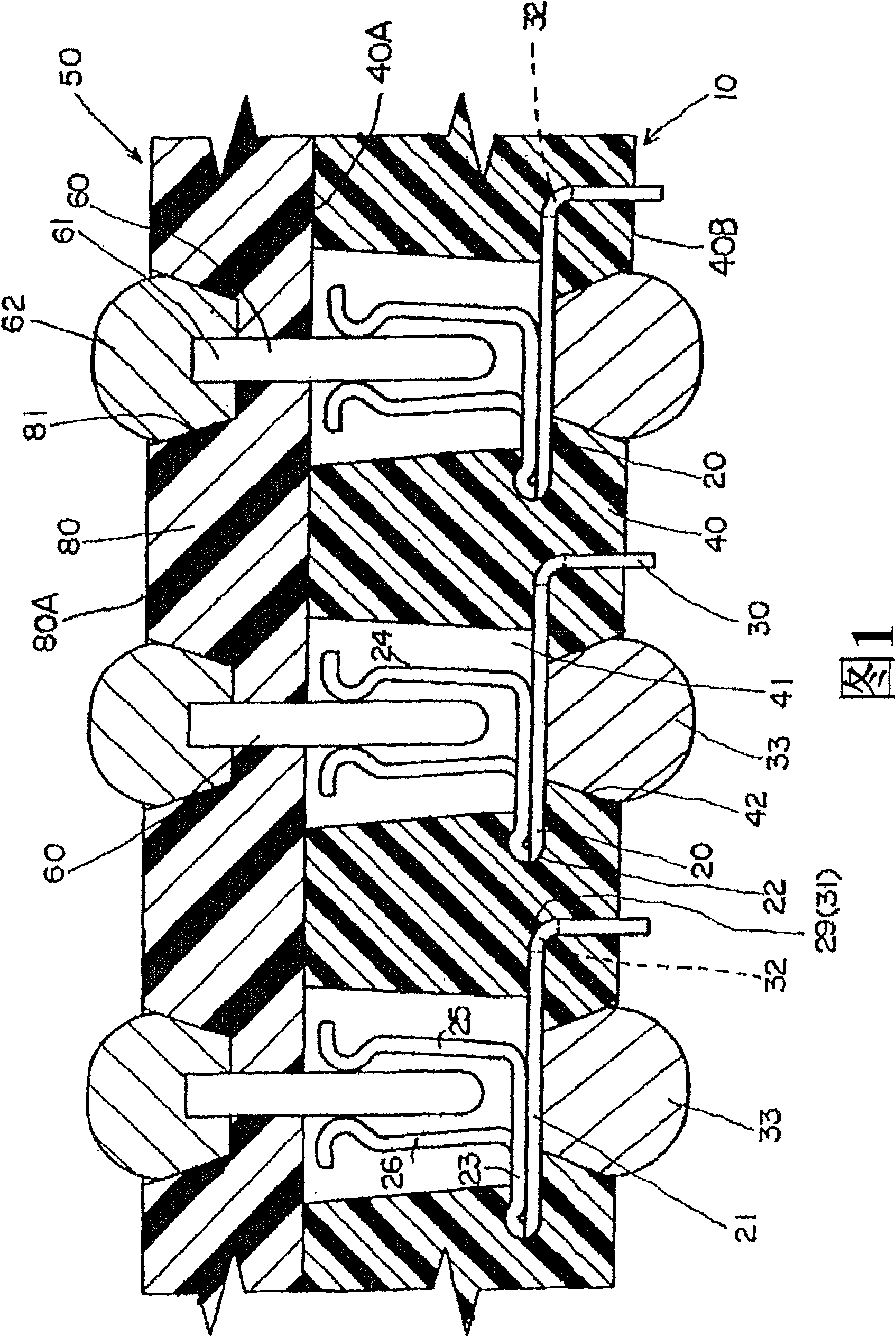

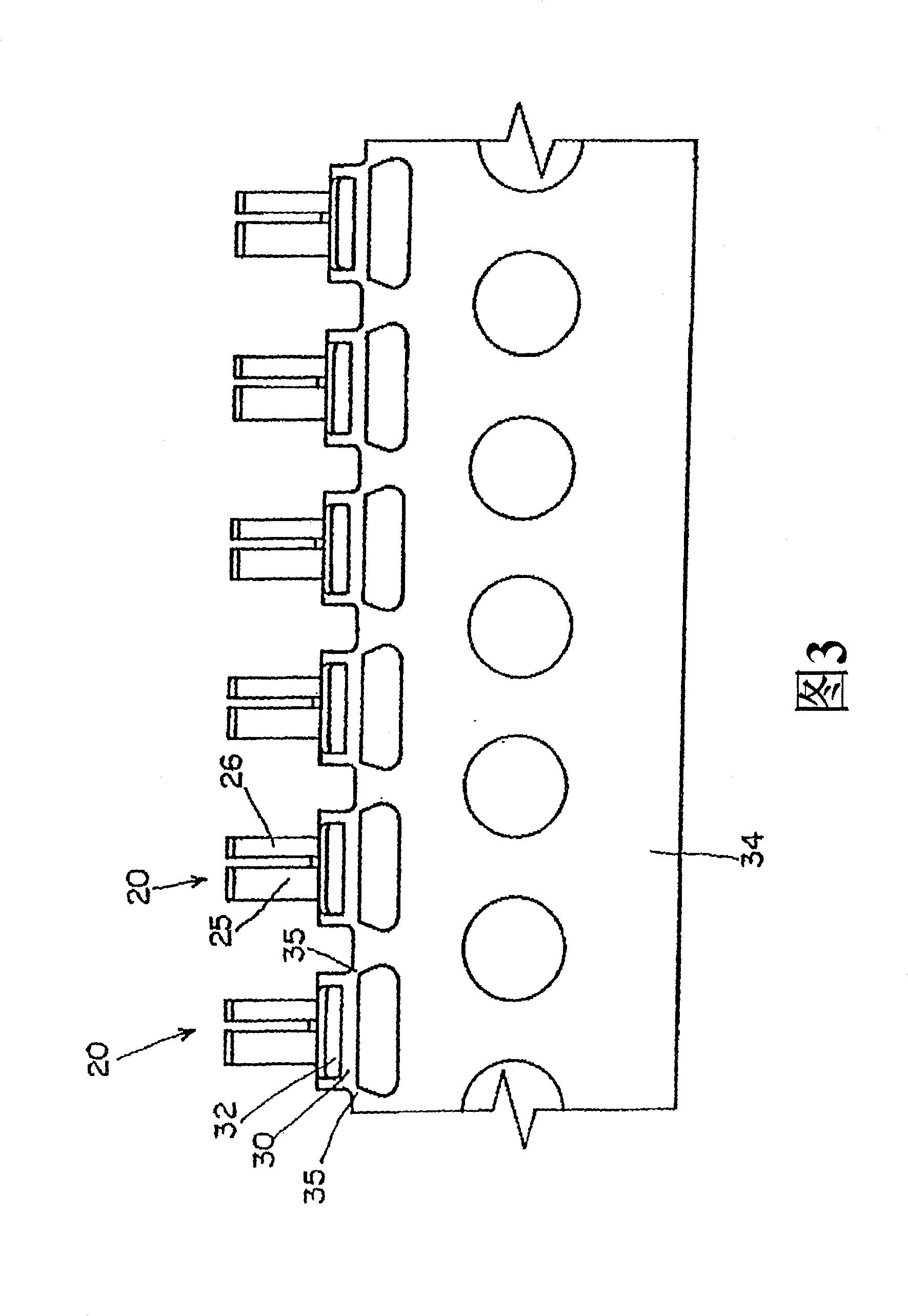

[0032] Referring to FIG. 1 , there is shown an electrical connector assembly comprising a connector 10 and a mating electrical connector 50 , both of which can be mated together. The connector 10 includes a plurality of terminals 20 arranged in a side-by-side sequence at a predetermined pitch, and a dielectric housing 40 is molded on the terminals 20, preferably by overmolding. The mating connector 50 includes a plurality of contact pins 60 arranged side by side in a one-to-one relationship corresponding to the terminals 20 on the connector of the present invention, and a dielectric housing 80 is overmolded on the contact pins 60 . As shown in FIG. 1 , the terminals 20 and the contact pins 60 are arranged at predetermined pitches in a right-to-left direction, and further, they are arranged in a direction perpendicular to the paper plane of FIG. 1 .

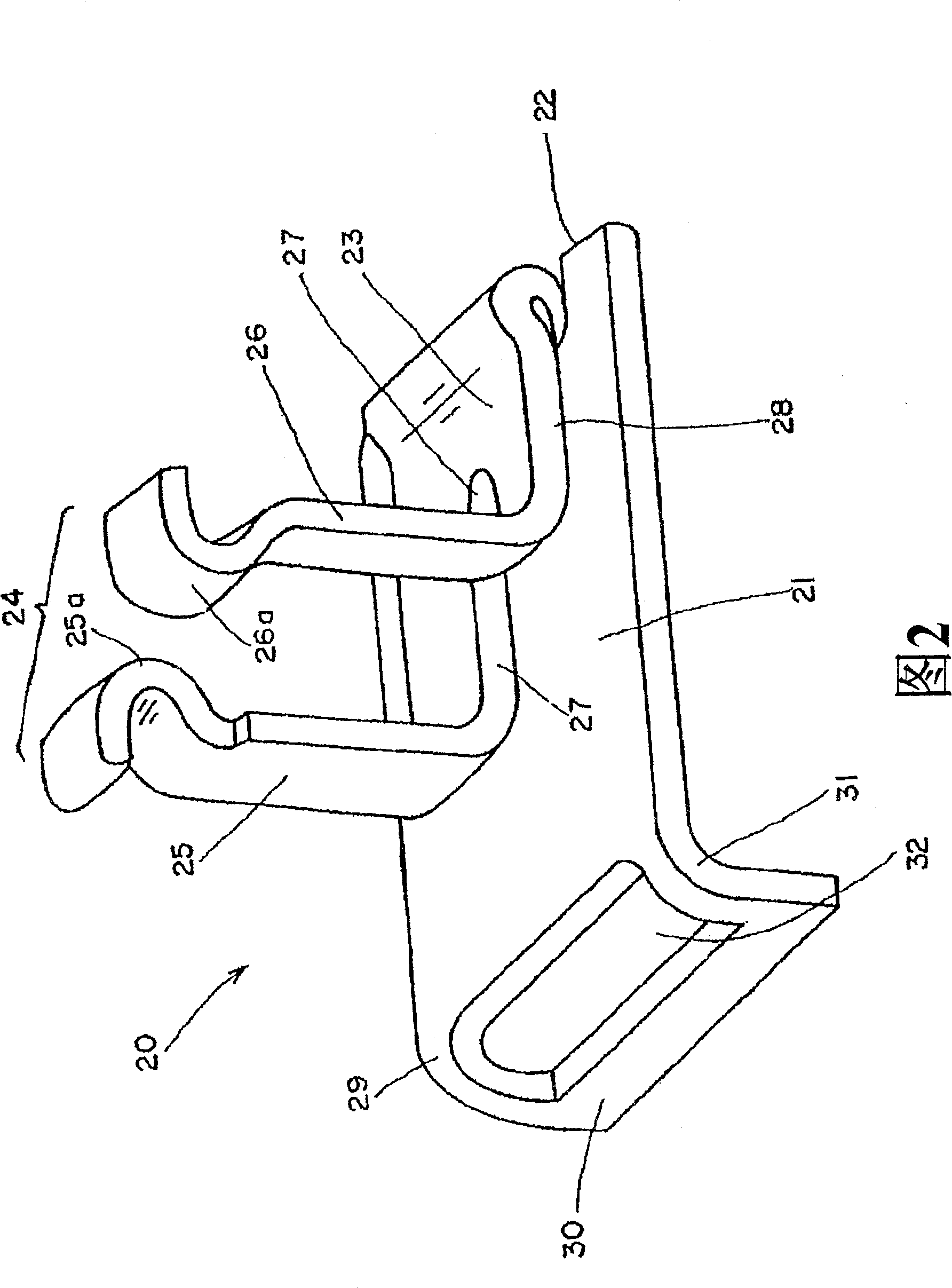

[0033] Each terminal 20 of the connector 20 is preferably produced by pressing and forming it from sheet metal in the shape sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com