Automatic guiding conveying machine of soft banner jacket for jacket tail cutting device

A conveying mechanism and automatic guiding technology, which is applied to electrical components, insulators, circuits, etc., can solve the problems of increased equipment manufacturing cost and complicated control, and achieve the effect of improving product quality, improving the speed of cutting tail, and good consistency of incision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The utility model is described in further detail by the following examples.

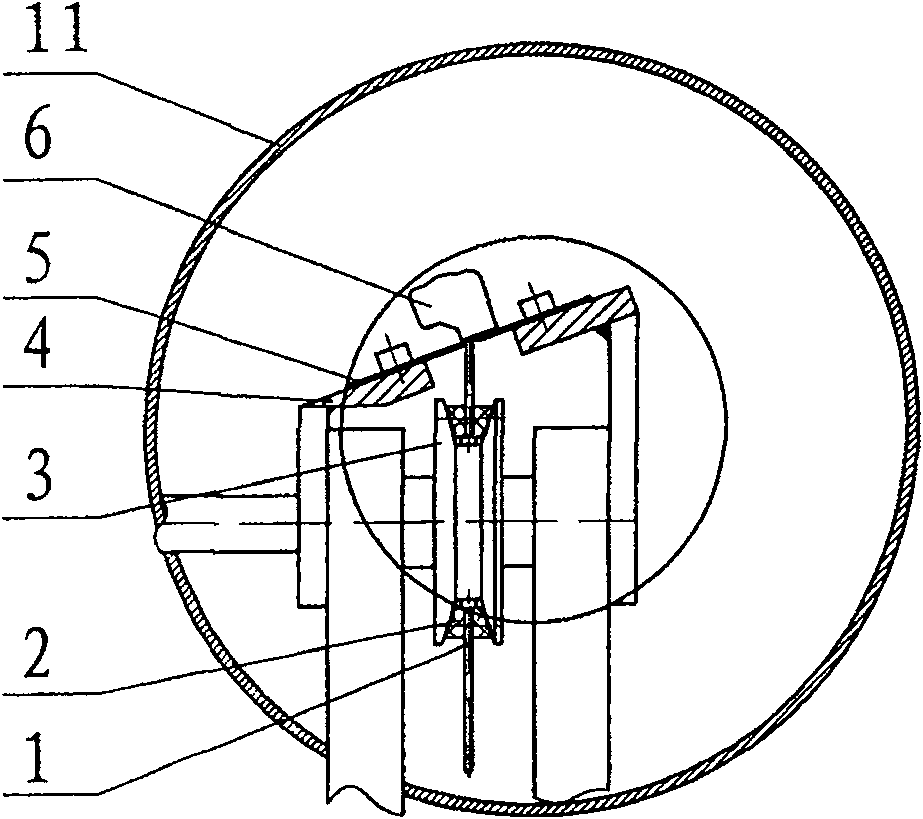

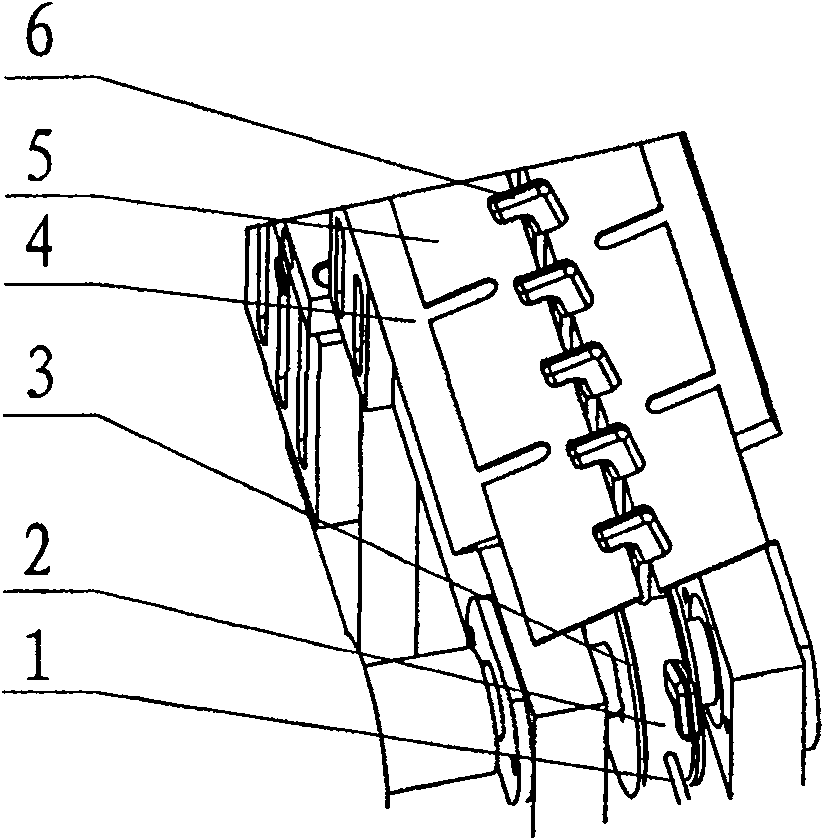

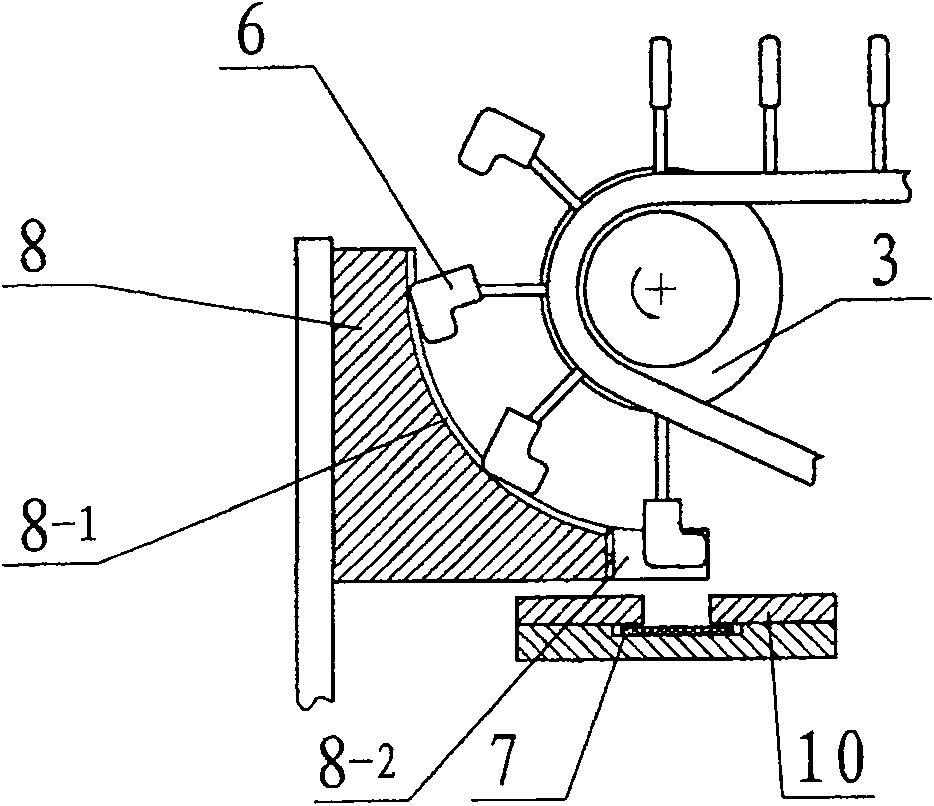

[0015] see figure 1 , figure 2 , image 3 , Figure 4 As shown, a soft flag-shaped sheath automatic guiding conveying mechanism for sheath tail cutting equipment of the utility model is composed of a soft flag-shaped sheath automatic sorting mechanism and a soft flag-shaped sheath automatic positioning and orientation mechanism. The soft flag-shaped sheath automatic sorting mechanism is composed of a conveyor belt 2 and a transmission wheel 3. A row of guide pins 1 perpendicular to the conveyor belt 2 and facing outward are evenly fixed on the conveyor belt 2. The transmission wheel 3 is fixed and supported on the frame. The transmission belt 2 passes through the inner hole of the drum 11 . The automatic positioning and orientation mechanism of the soft flag-shaped sheath is composed of a base plate 5, a guide plate 4, an arc-shaped guide groove 8, a conveyor belt 7, a guide plate 9 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com