A method for automatically positioning and cutting tails of fresh corn cobs

An automatic positioning and fresh corn technology, which is applied in metal processing and other fields, can solve the problems of low work efficiency, high labor cost, and different lengths of fresh corn cobs, so as to improve the efficiency and speed of tail cutting The effect of improving and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

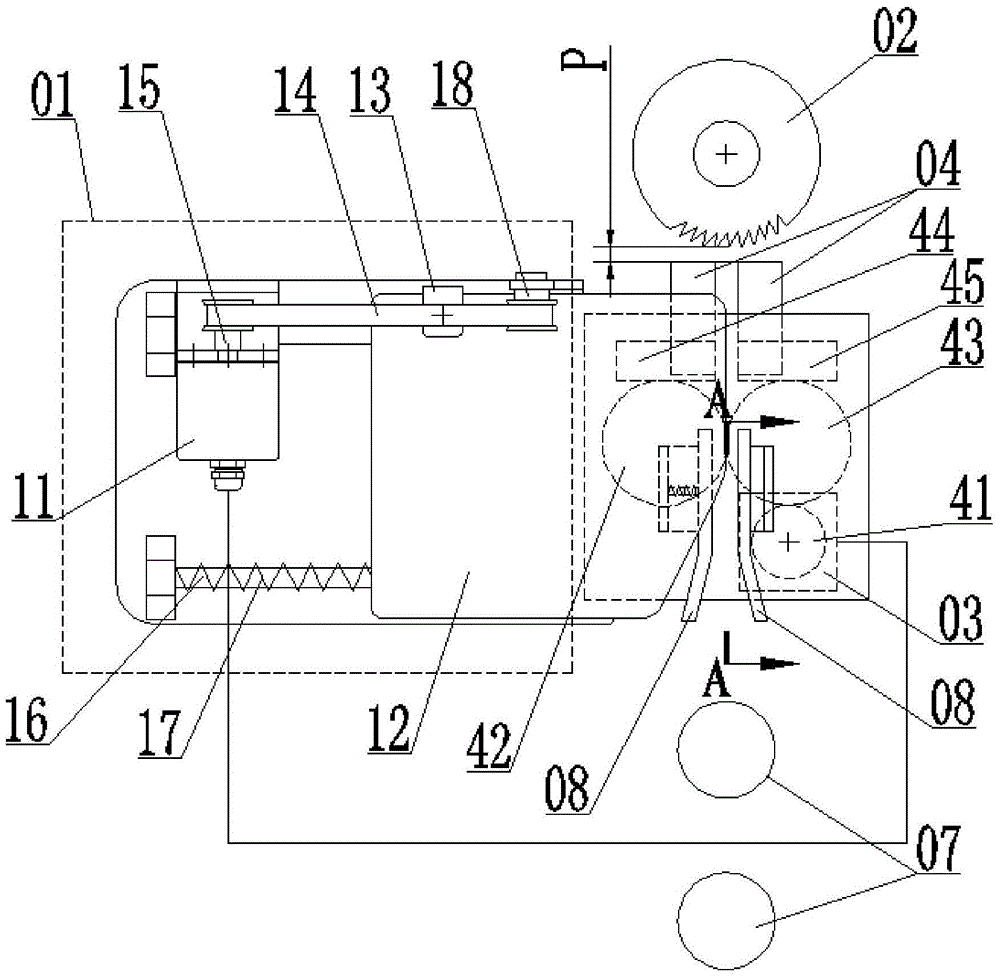

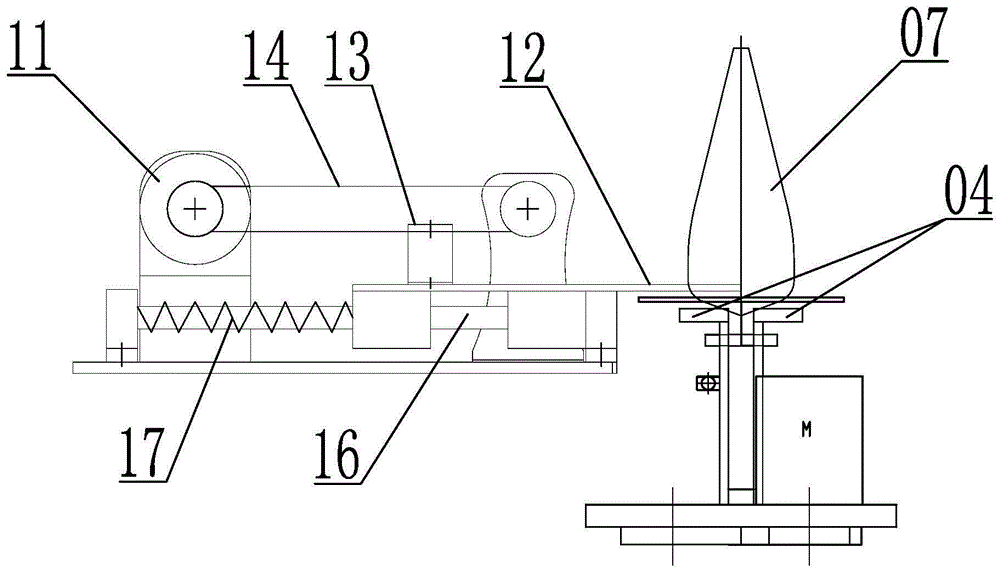

[0018] Specific implementation mode one: combine Figure 1 to Figure 3 Note that the method in this embodiment is implemented through the following steps:

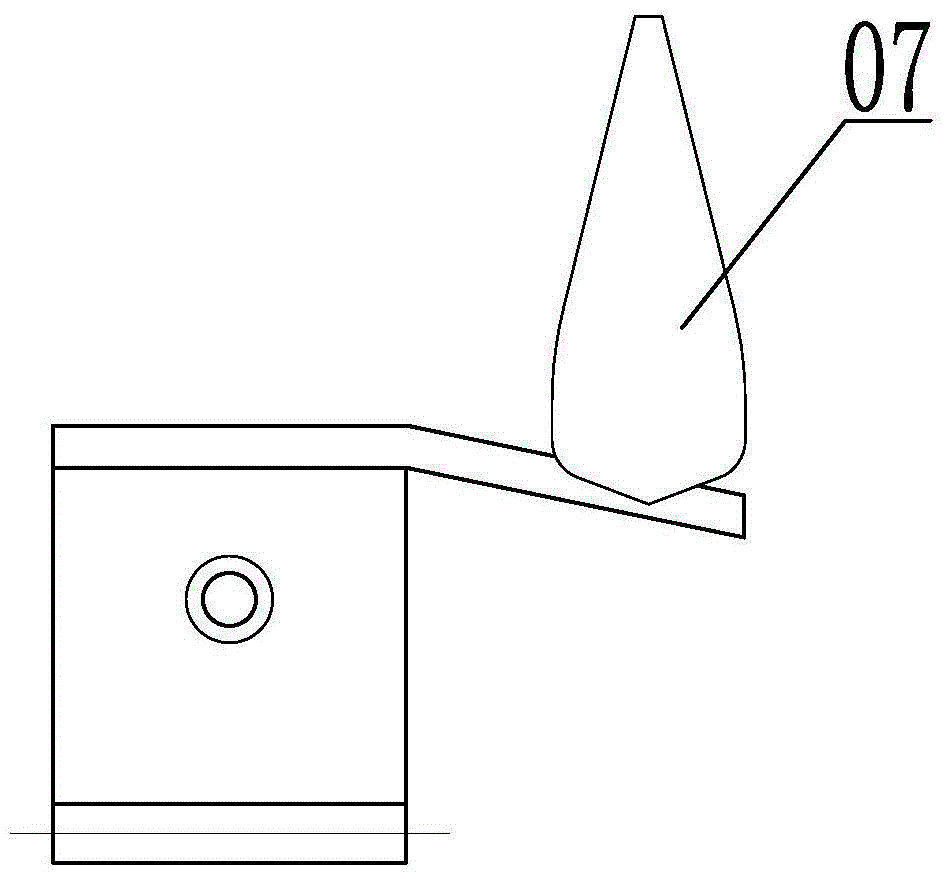

[0019] Step 1: Clamp the corn cobs; put the tails of the corn cobs 07 to be trimmed vertically downwards into the corn cob clamping device of the corn cob transmission mechanism, the distance between two adjacent corn cobs 07 to be trimmed same;

[0020] Step 2: Press out the tail handle;

[0021] The corn cobs to be trimmed 07 are transferred to the entrance of the two square extruded plate assemblies 08 with the corn cob clamping device, and the tail tips of the corn cobs to be trimmed 07 are placed in the distance between the two square extruded plate assemblies 08 , the tail of the corn cobs to be trimmed 07 is attached to the top surface of each square extruded plate assembly 08, and the corn cob clamping device drives the corn cobs to be trimmed 07 to advance along the long side of the square extruded plate assembl...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination Figure 1 to Figure 3 Note that the diameter of the rotary saw blade 02 in this embodiment is 70 mm to 130 mm, and the rotational speed of the rotary saw blade 02 is 3 thousand revolutions per second to 10 thousand revolutions per second.

[0035] Since the diameter of the rotary saw blade 02 directly affects the cutting speed of the rotary saw blade 02, the diameter of the rotary saw blade 02 and the rotating speed of the rotary saw blade 02 in this embodiment are the optimal value range of the cutting speed of the rotary saw blade 02, ensuring that the corn cob The tail shank is cut off smoothly and quickly, and at the same time, the wear and tear on the rotary saw blade 02 is small, and the service life of the rotary saw blade 02 is prolonged.

[0036] The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination Figure 1 to Figure 3 Note that the distance P between the outlet ends of the two pallets 04 and the rotary saw blade 02 in this embodiment is 1 mm to 10 mm.

[0038] The distance P in this embodiment can ensure that the corn cobs extruded by the tail stalk can be cut off smoothly. If the distance P is too large, the pulp at the end of the corn cobs extruded by the tail stalk will be cut off, resulting in waste; if the distance P is too small , It is easy to cause damage to the two pallets 04.

[0039] The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com