Semi-automatic cigarette sorting line

A sorting line, semi-automatic technology, applied in sorting and other directions, can solve the problems of low efficiency, low labor intensity of workers, limited speed, etc., to achieve the effect of improving sorting efficiency, improving smoking efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

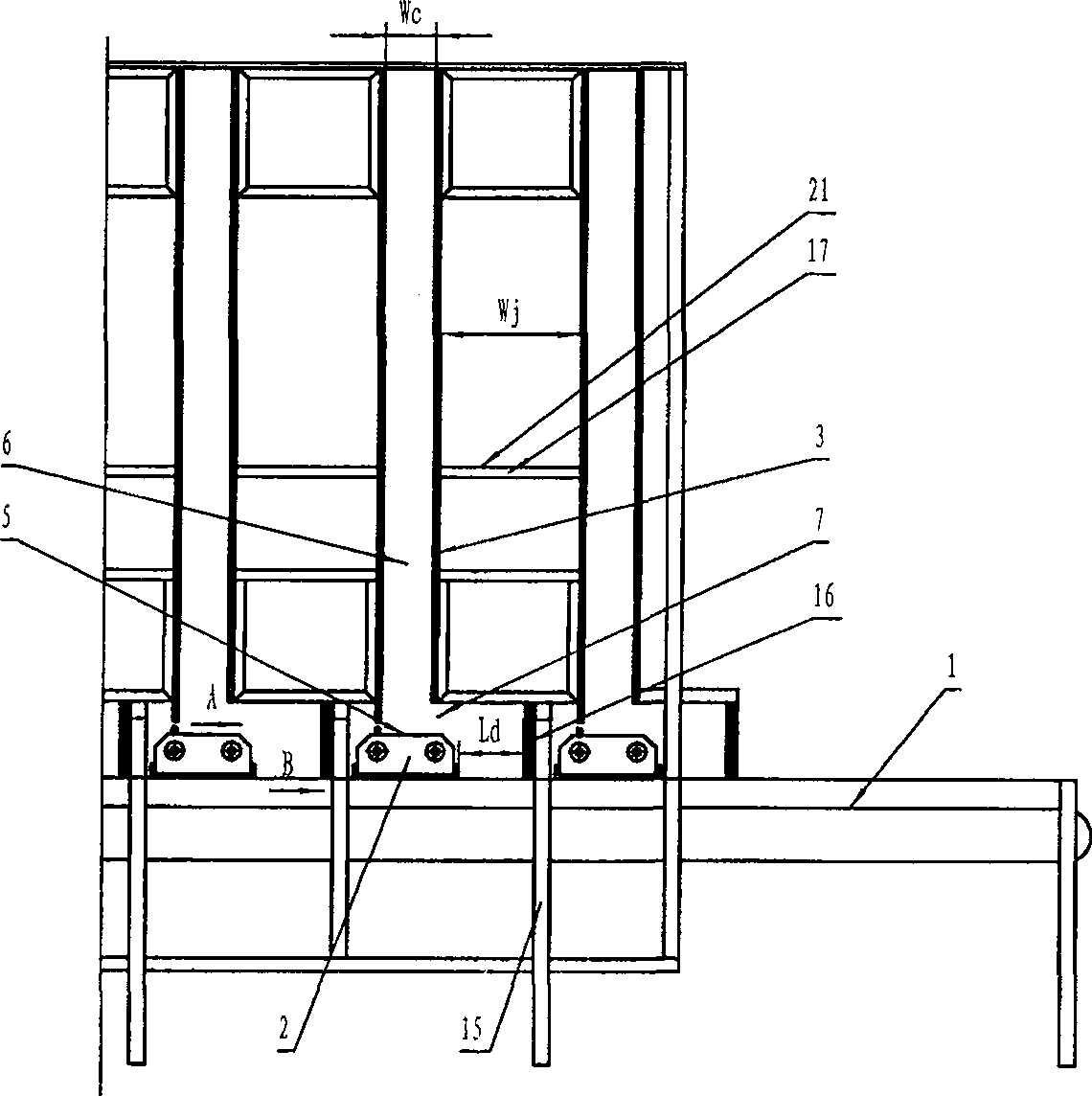

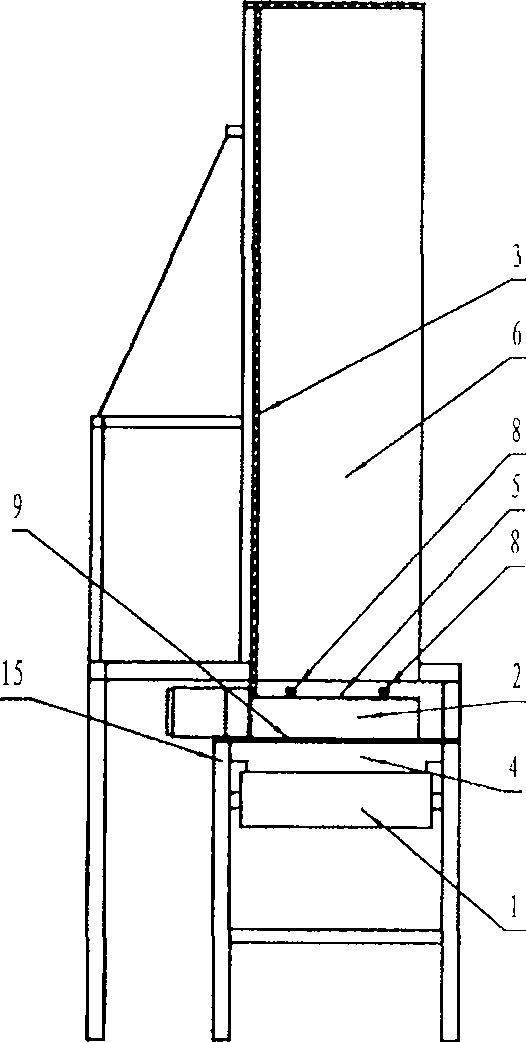

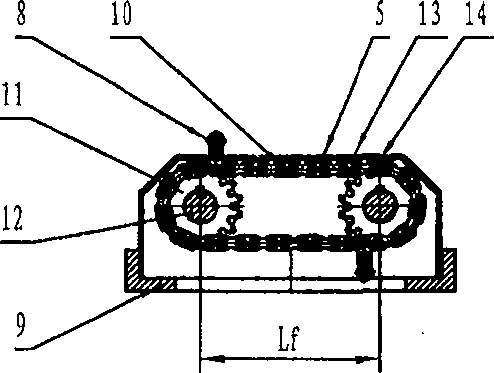

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] refer to Figure 1 to Figure 5 , a semi-automatic cigarette sorting line, including a frame 15, a conveyor belt 1, and no less than two cigarette sorting execution units, and the cigarette sorting execution unit includes a sorting actuator 2 and a cigarette temporary storage bin 3, the sorting actuator 2 is placed across the top of the conveyor belt 1, the space between the bottom of the sorting actuator 2 and the conveying surface of the conveyor belt 1 is a cigarette conveying channel 4, and the sorting execution The direction A of pulling out the cigarettes of the device 2 is parallel to (consistent with or opposite to) the conveying direction B of the conveyor belt; The pallet 5 is the bottom of the temporary cigarette storage bin 3, the pallet 2 of the sorting actuator and the temporary cigarette storage bin 3 form a temporary cigarette storage space 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com