Inspection apparatus and method

A technology of inspection device and discriminant function, applied in measuring device, instrument, measuring ultrasonic/sonic/infrasonic wave, etc., can solve problems such as degradation of discriminant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

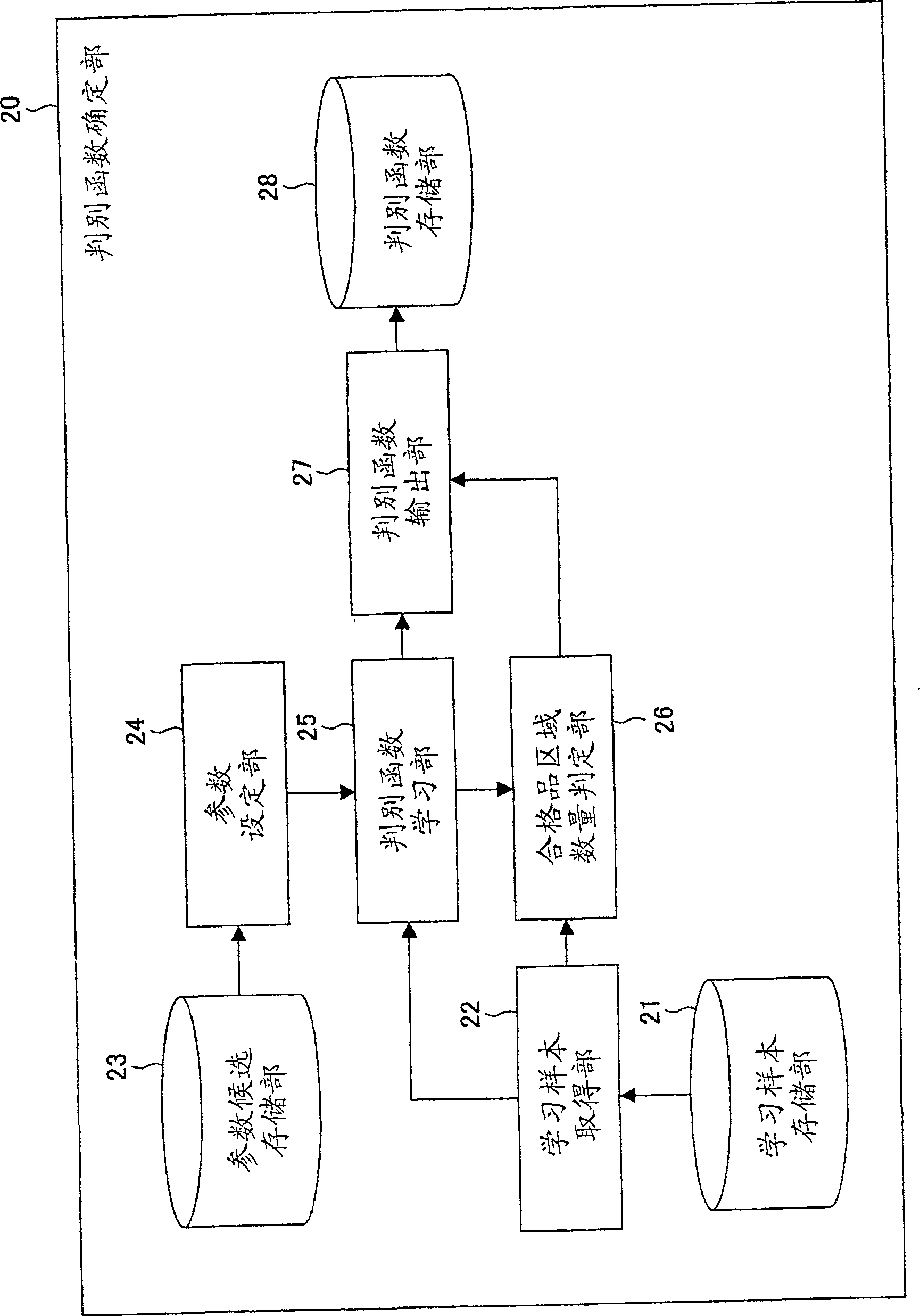

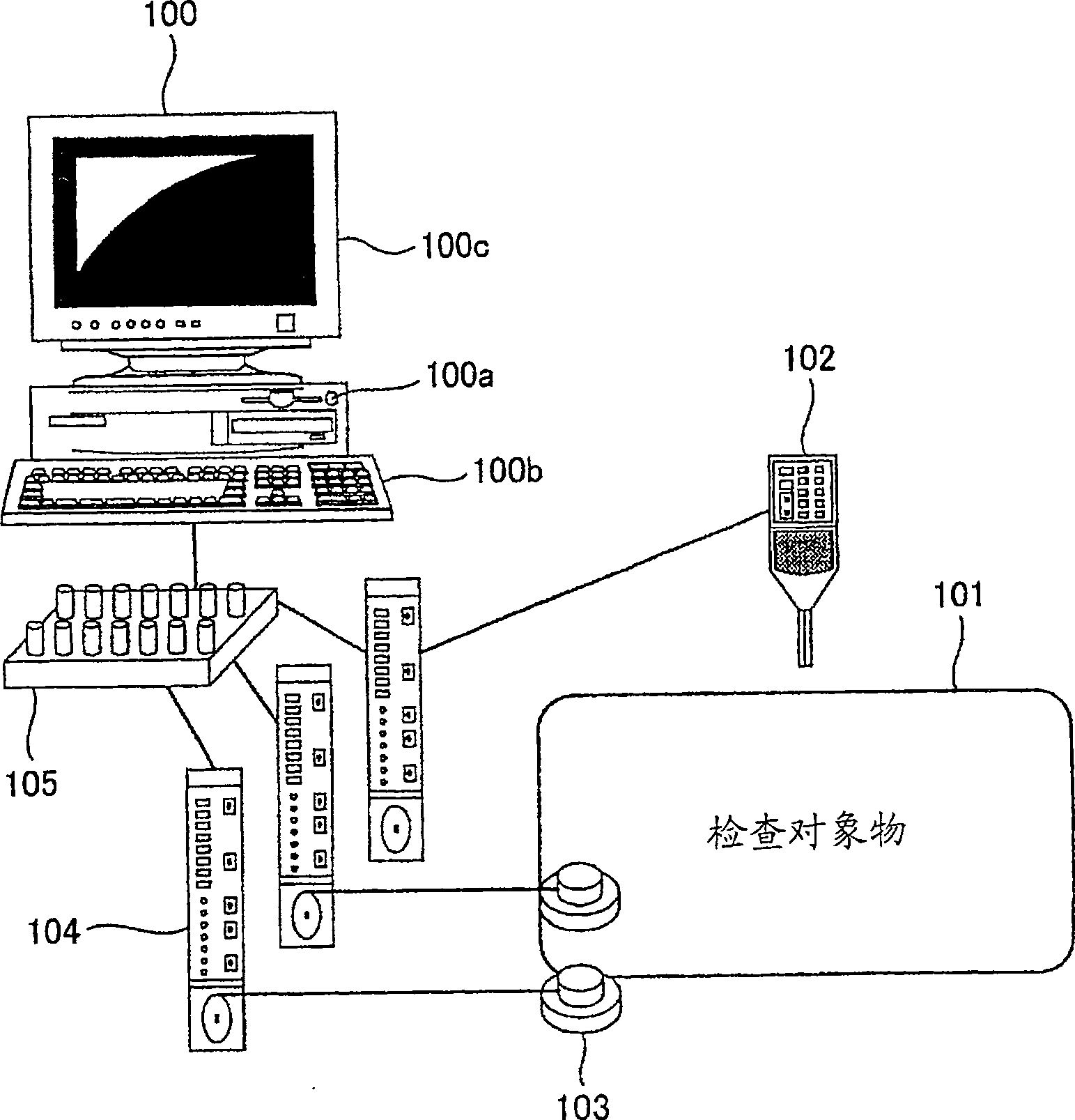

[0094] figure 2 It is an explanatory diagram showing an outline of the configuration of the inspection device 100 according to the present embodiment. figure 1 is a functional block diagram showing the configuration of the discriminant function determination unit 20 included in the inspection device 100 .

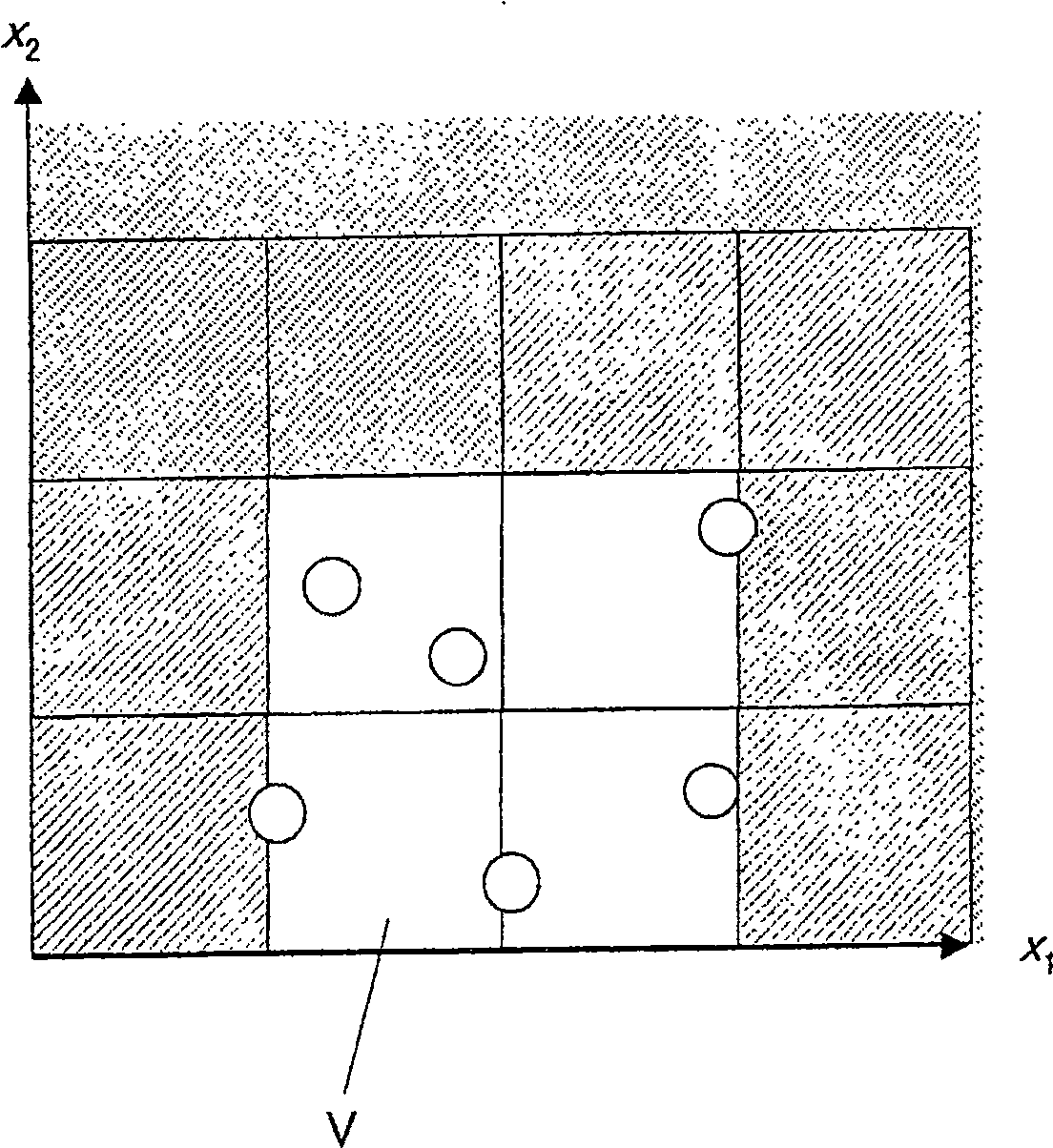

[0095] The inspection apparatus 100 of the present embodiment extracts feature quantities from the input measurement data of the inspection object. The inspection device 100 judges whether the sample is qualified or not through non-parametric discrimination based on the extracted feature quantity. And in particular, the inspection apparatus 100 has a discriminant function determination unit 20 . This discriminant function determination unit 20 has the following functions: (1) to determine whether the discriminant function used in the non-parametric one-class ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com