Etching apparatus and technology thereof

A technology of etching equipment and etching tank, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the difficulty of extracting hydrogen peroxide or ammonium hydroxide, the unstable etching rate of copper or silver film, and affect the known etching equipment Reliability and other issues, to avoid gas embolism, maintain stable etching rate, and reduce irritating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

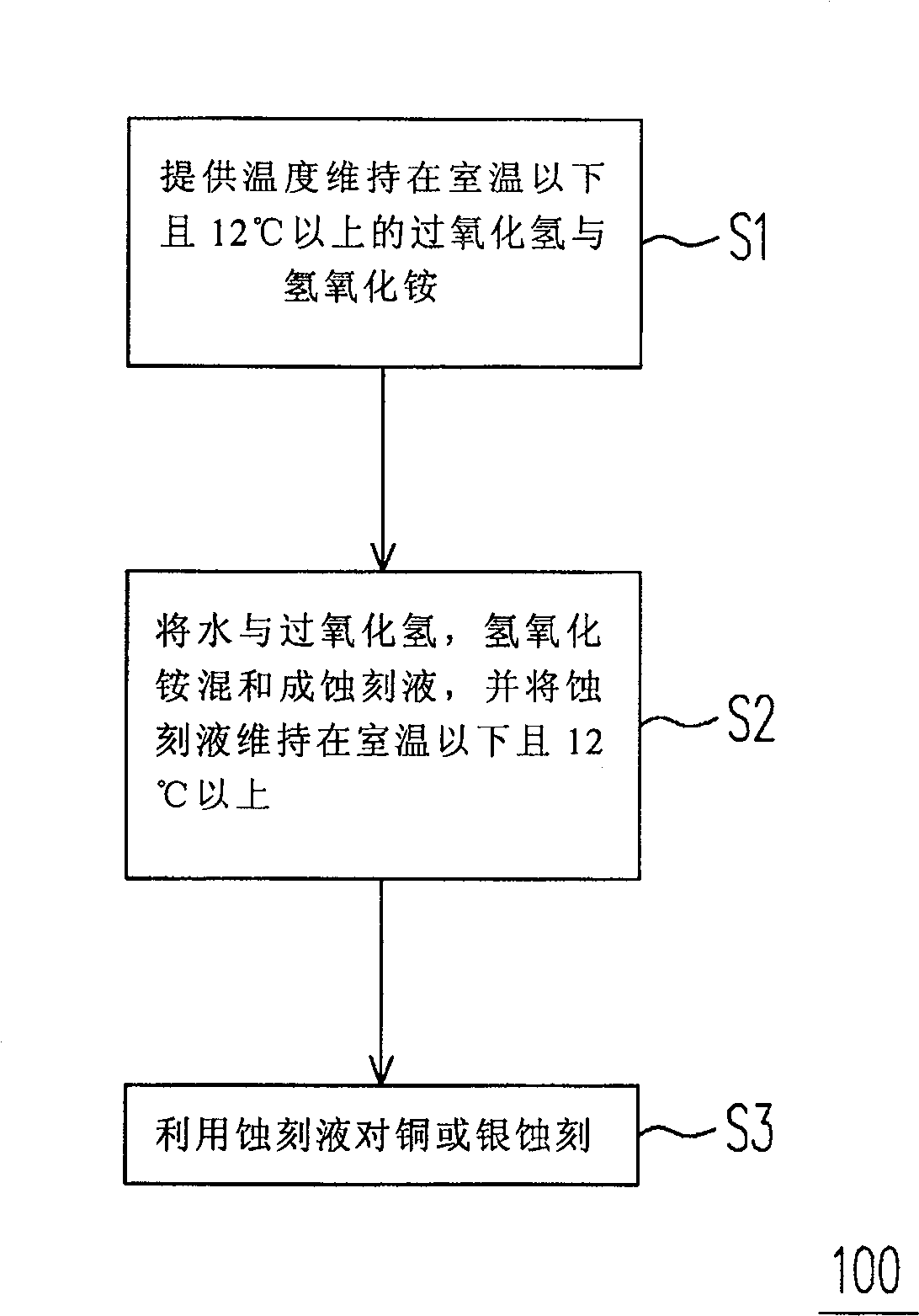

[0040] Please refer to figure 1 , The etching process 100 includes the following steps. First, as shown in S1, hydrogen peroxide and ammonium hydroxide are provided, and the temperature thereof is below room temperature and above 12 degrees Celsius. The volatilization speed of hydrogen peroxide and ammonium hydroxide is slower than the volatilization speed of hydrogen peroxide and ammonium hydroxide at room temperature without temperature control in the known technology. In a preferred embodiment, the temperature of hydrogen peroxide and ammonium hydroxide is between 12°C and 18°C.

[0041] Then, as shown in step S2, hydrogen peroxide, ammonium hydroxide and water within the above temperature range are mixed to form an etching solution, and the temperature of the etching solution is also kept below room temperature and above 12 degrees Celsius. In a preferred embodiment, the water used in the etching process 100 is, for example, deionized water, and the weight ratio of the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com