Patents

Literature

34results about How to "Evaporation rate is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

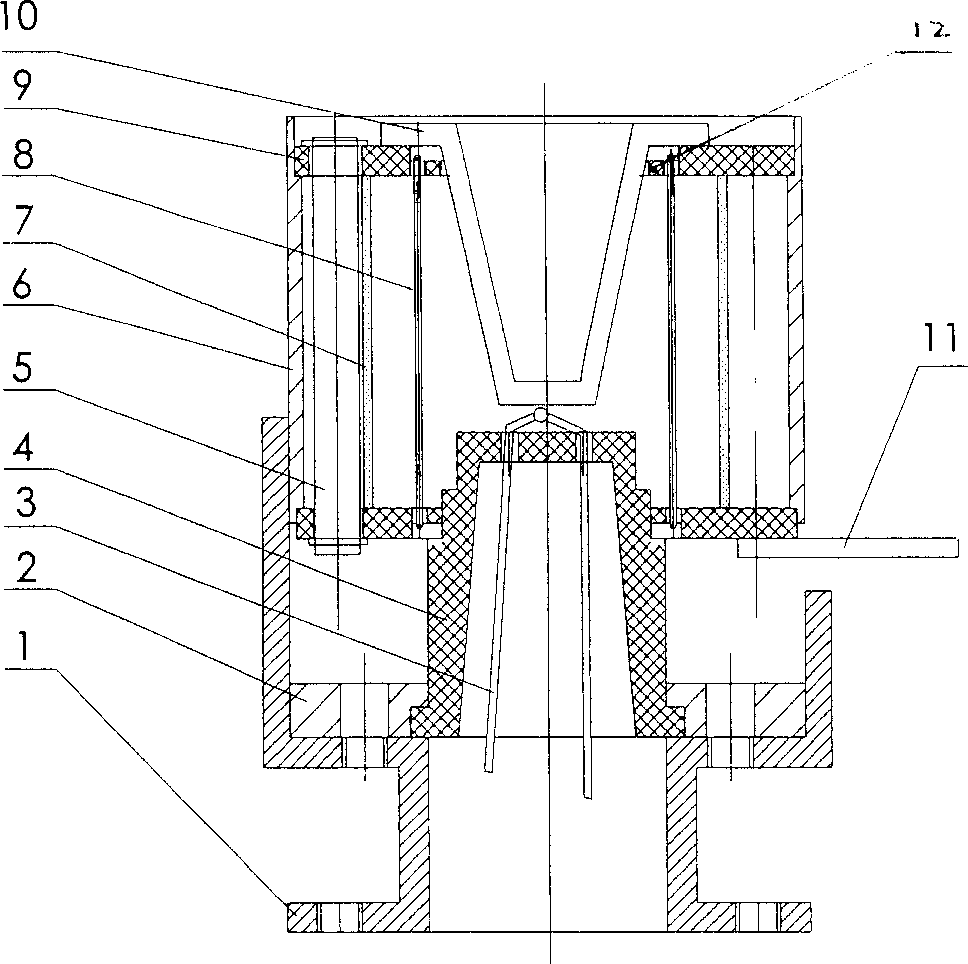

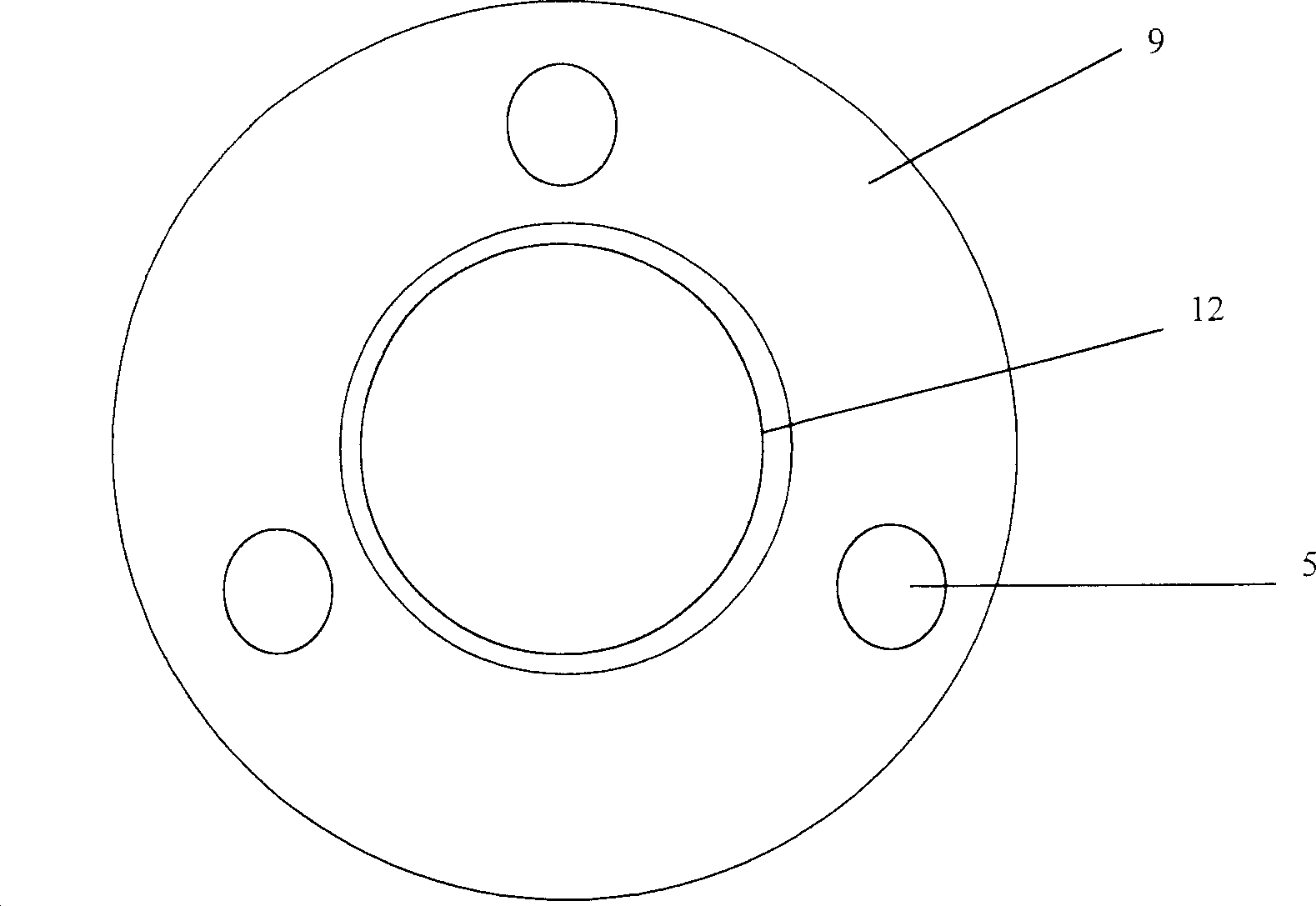

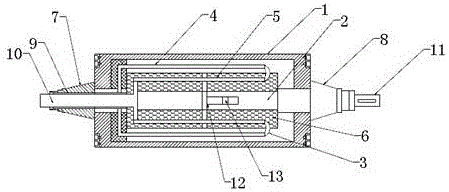

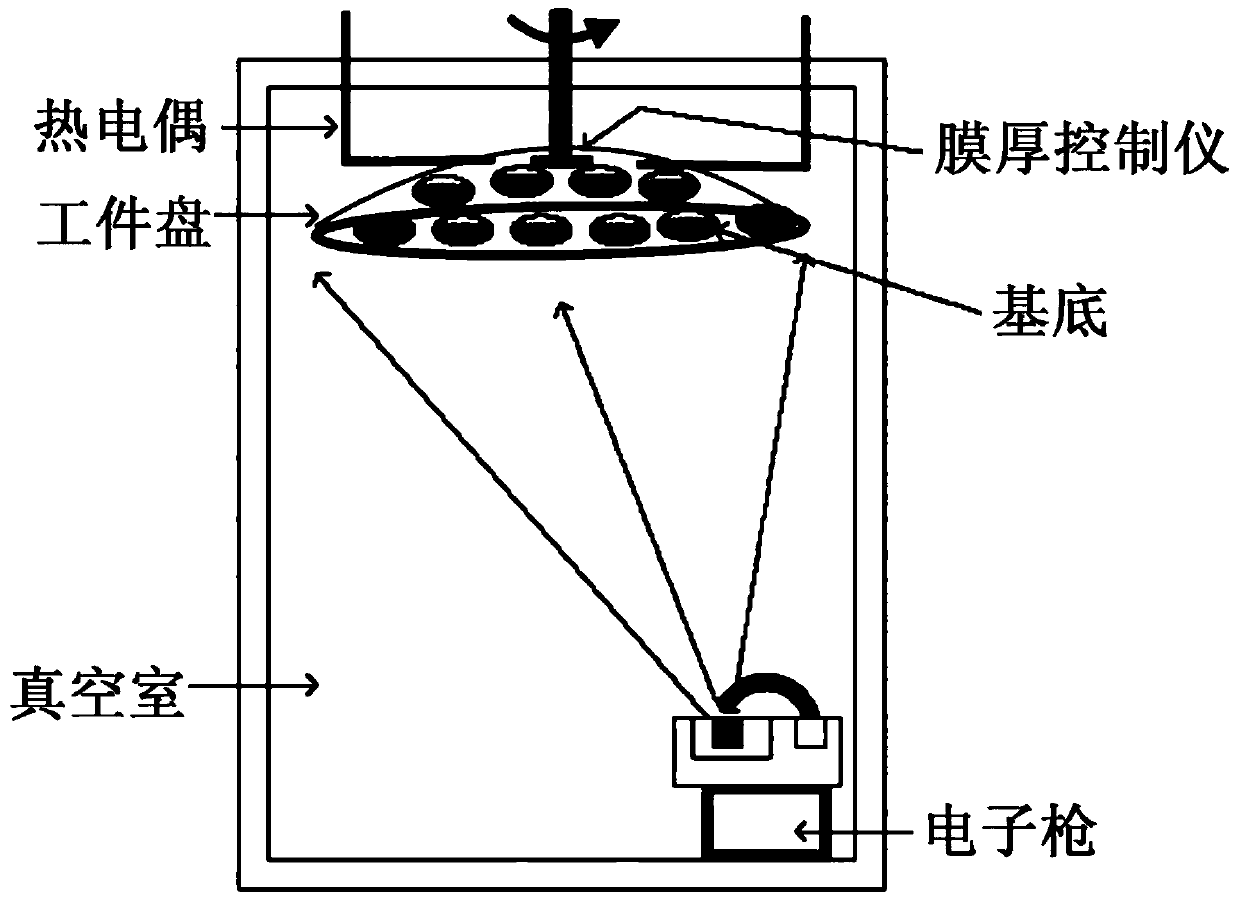

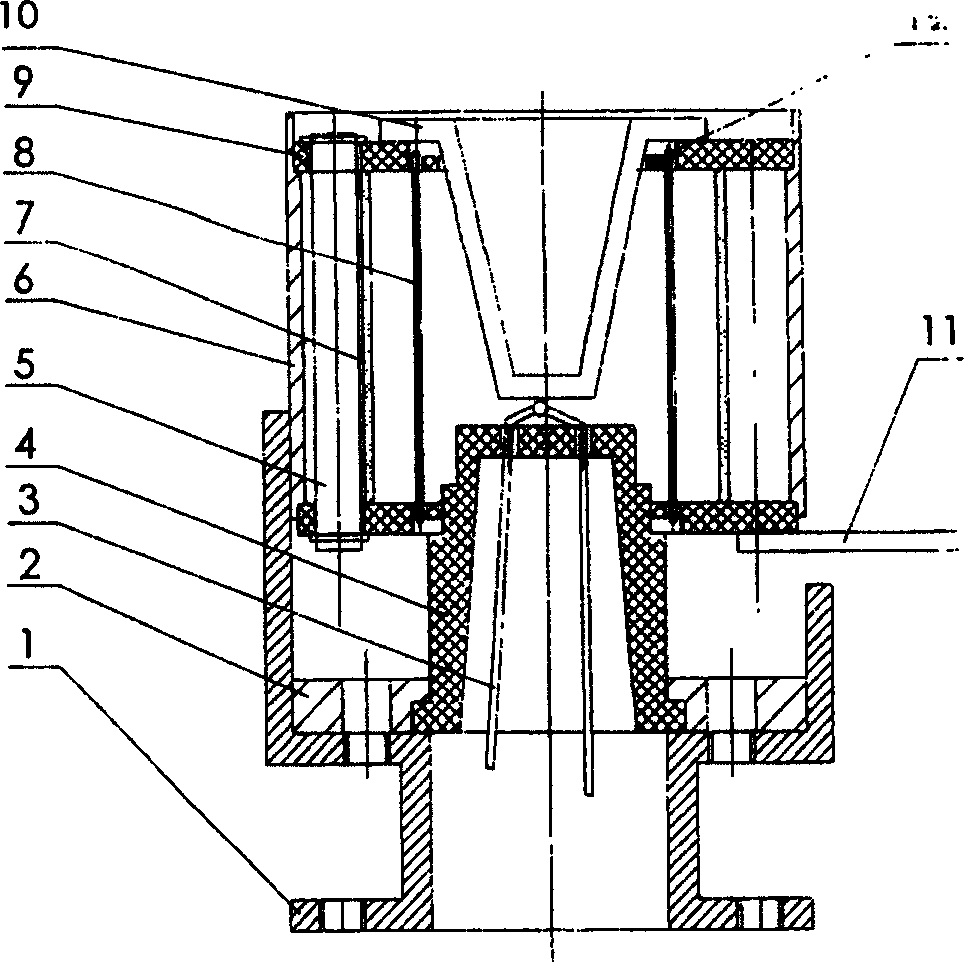

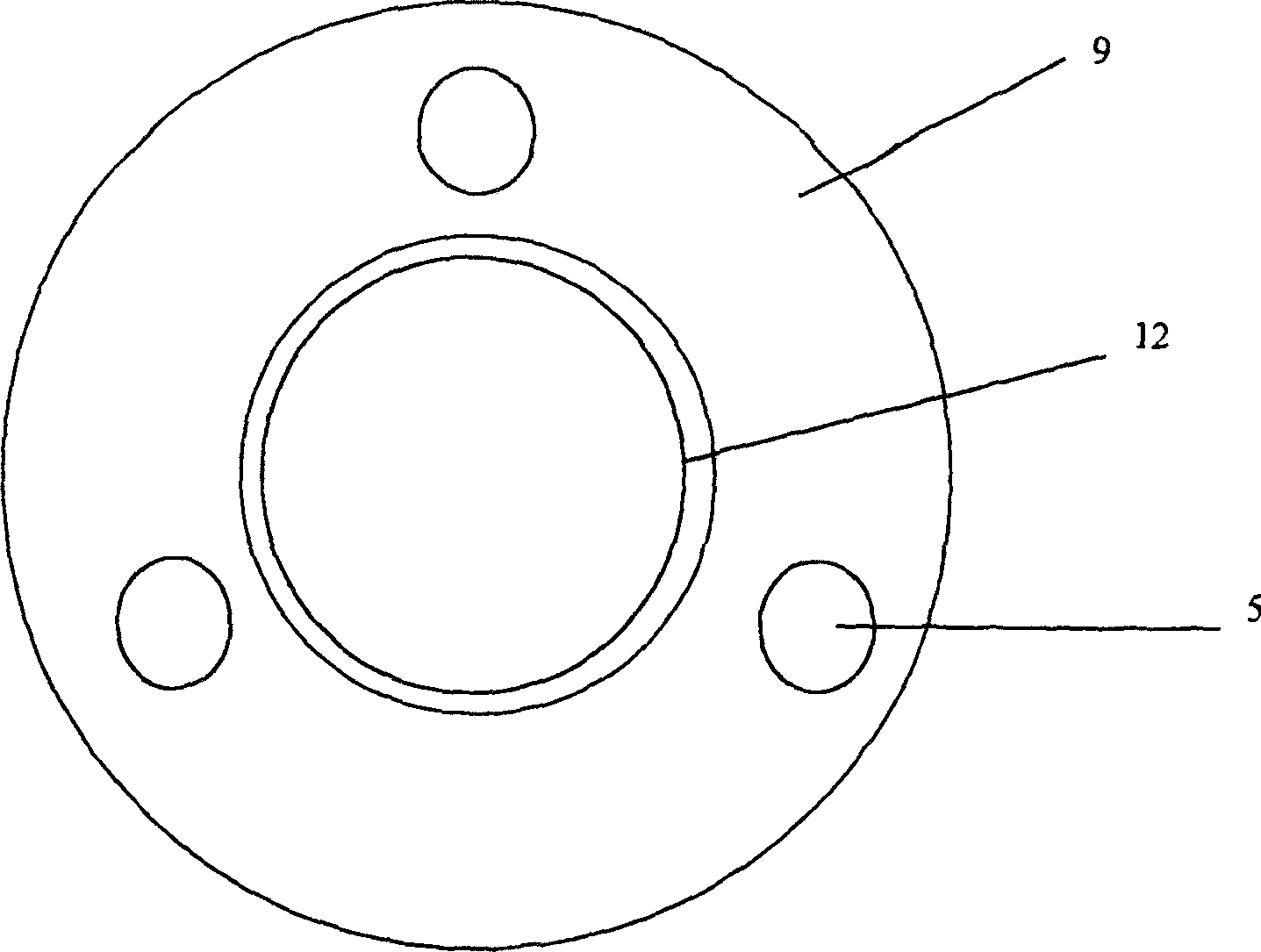

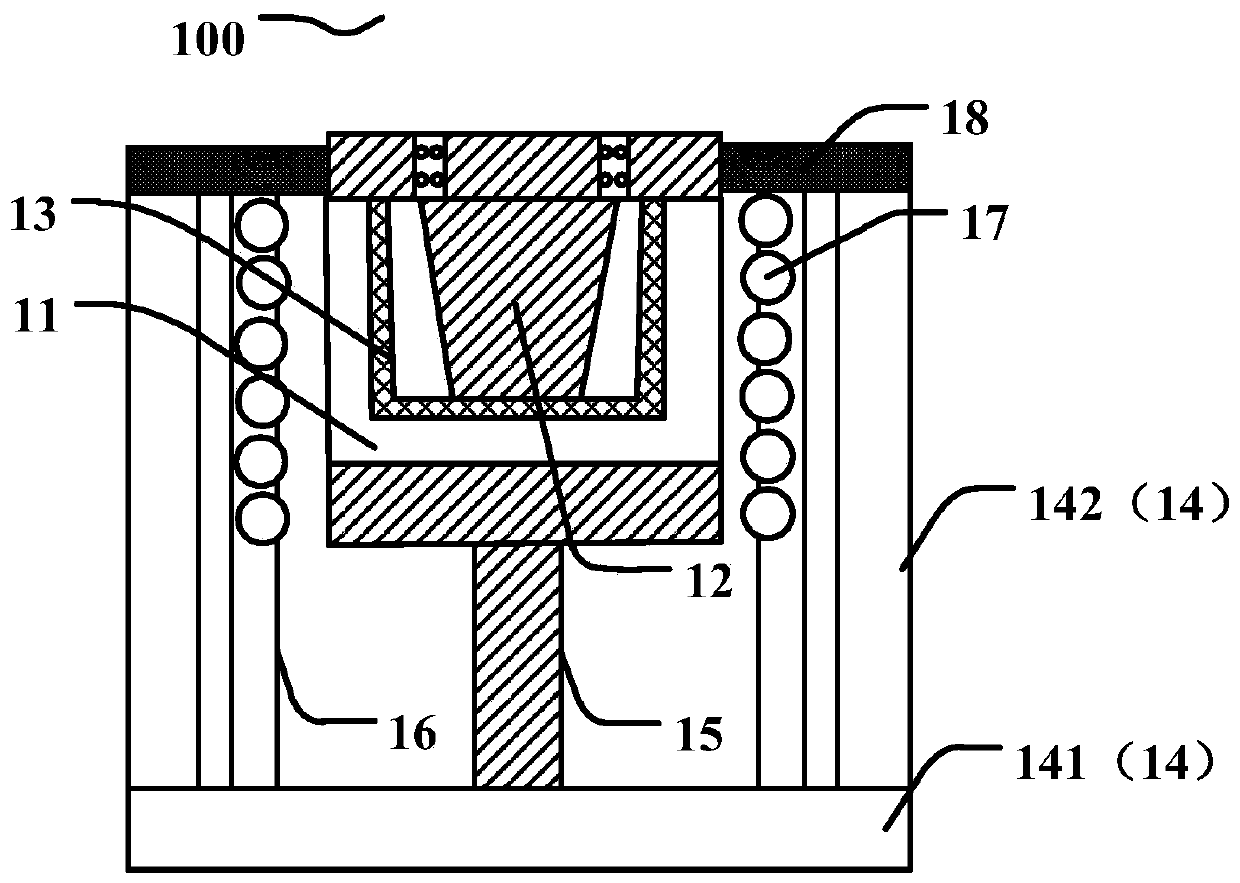

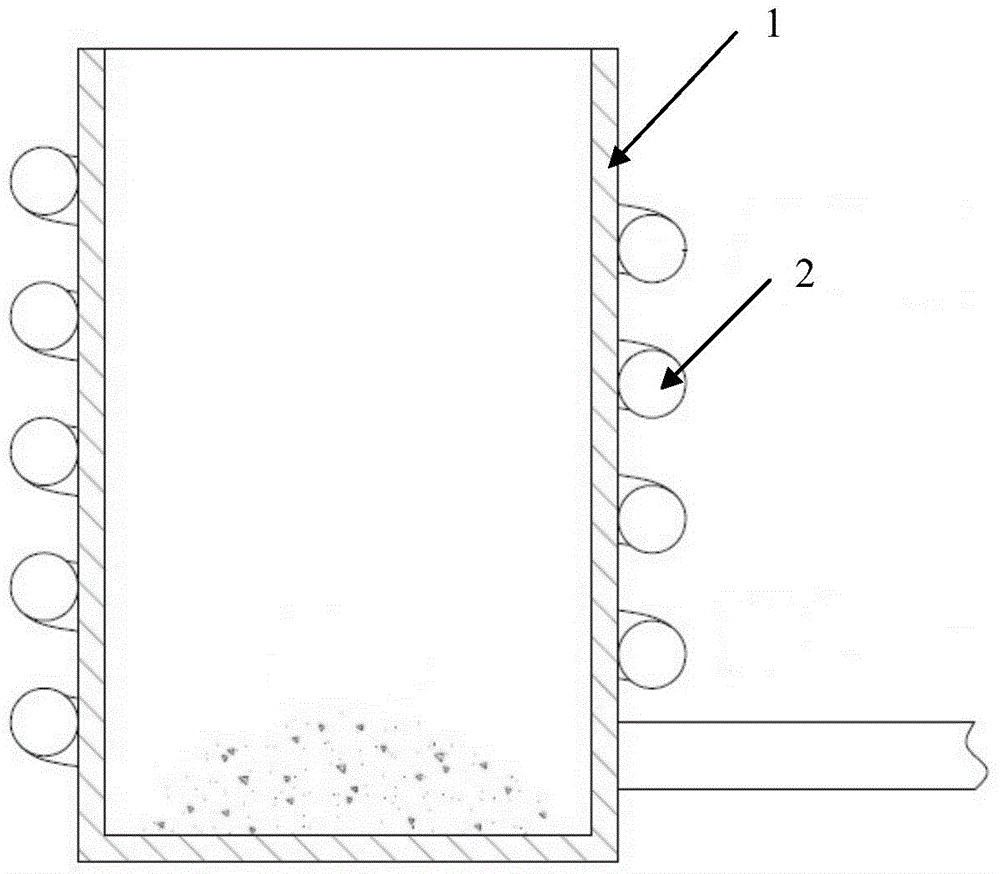

Crucible type evaporator source used for film plating machines in organic electrofluorescence type

InactiveCN1431339AImprove insulation effectEasy to take outVacuum evaporation coatingSputtering coatingOrganic filmHeating furnace

A crucible-type evaporator for the machine used to plate electroluminescent organic film is composed of supporting base, temp-measuring thermocuple system, crucible, and heating furnace which consists of upper and lower No.95 ceramic rings, cylindrical quartz glass as internal shielding layer, cylindrical stainless steel as external shielding layer, and Mo wire embedded in the inner surfaces of two ceramic rings. Its advantages are long service life, good temp control, stable evaporating speed, and high thermal insulating performance.

Owner:JILIN UNIV

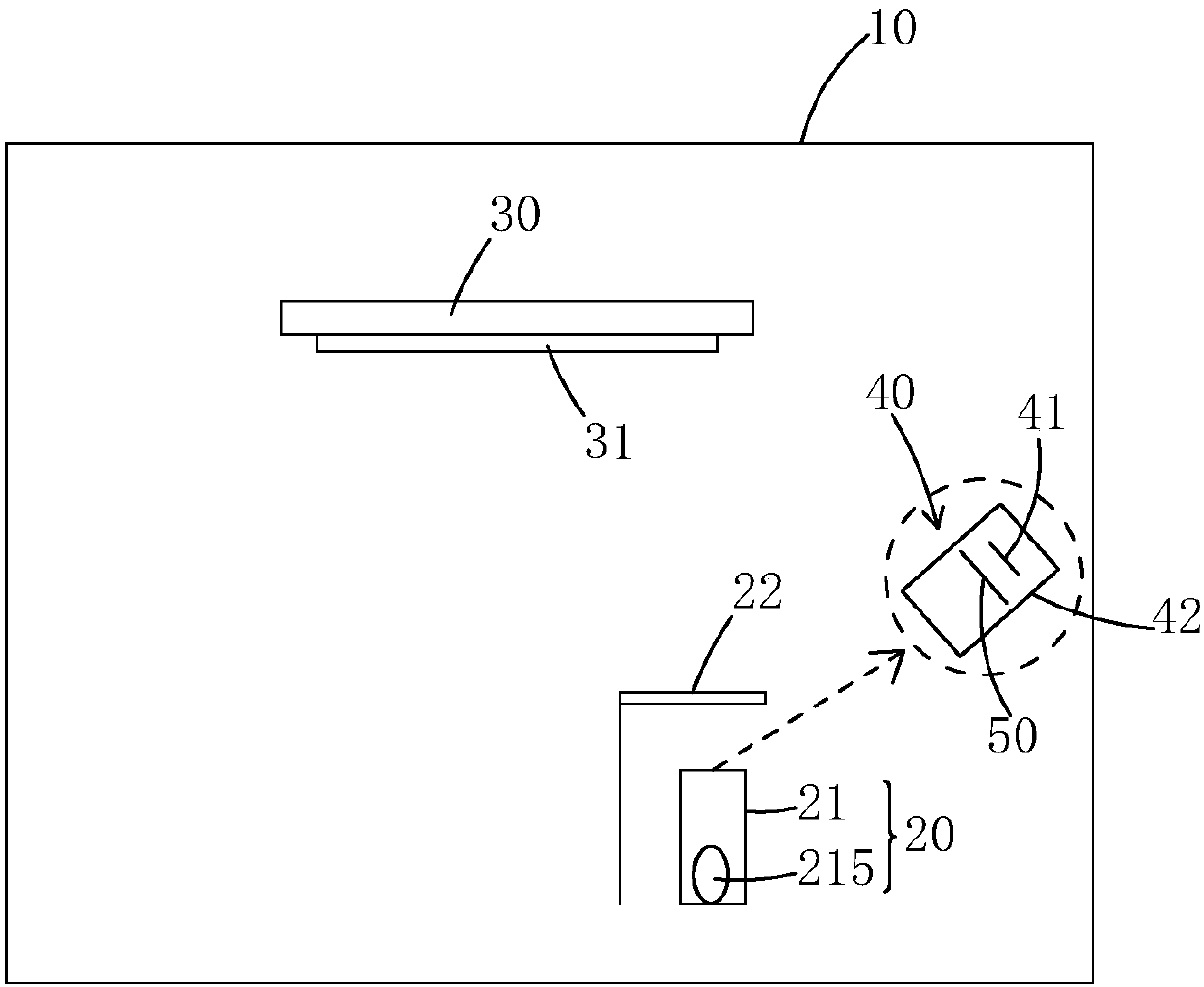

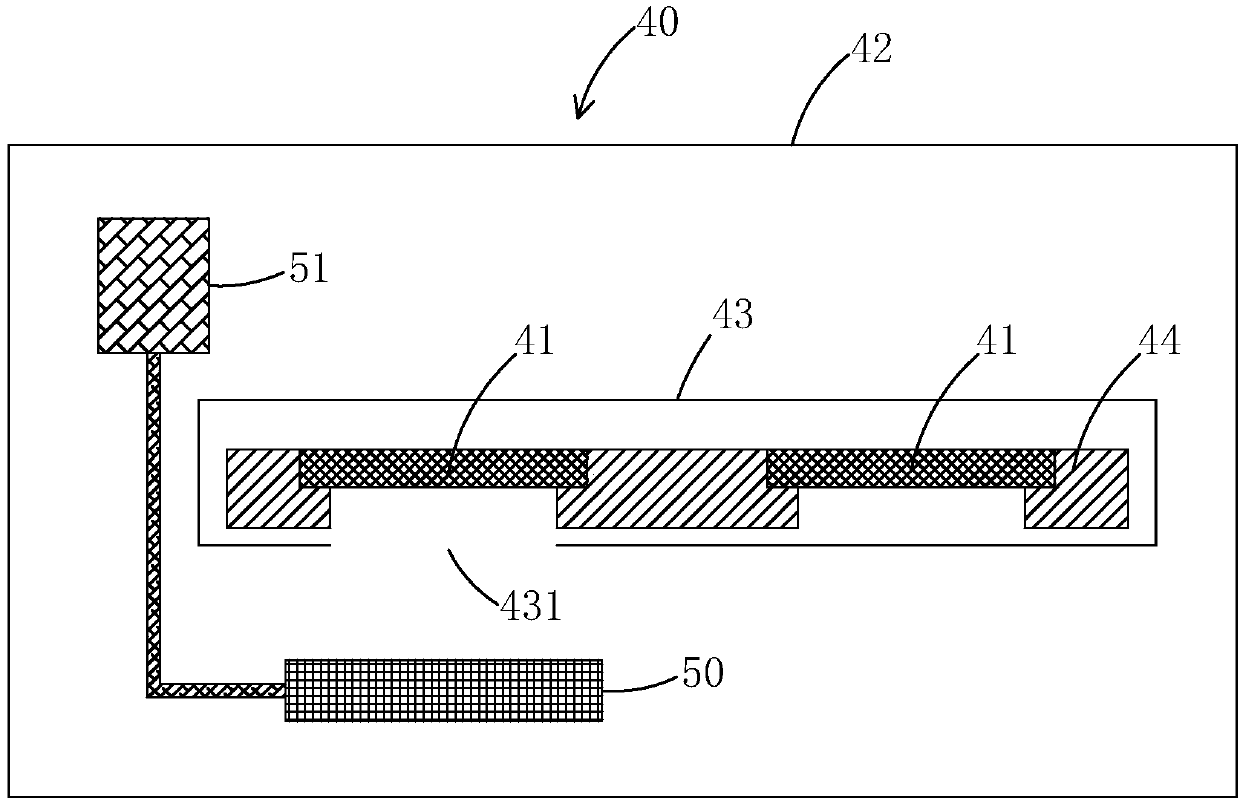

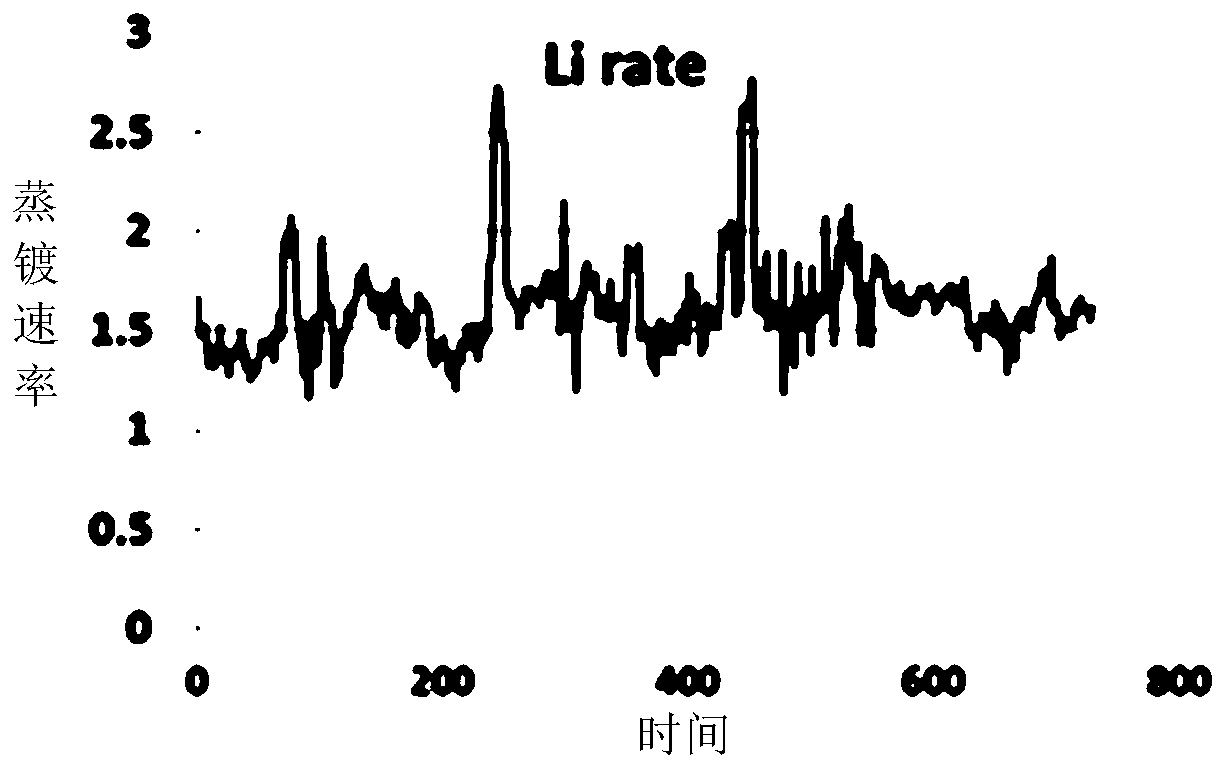

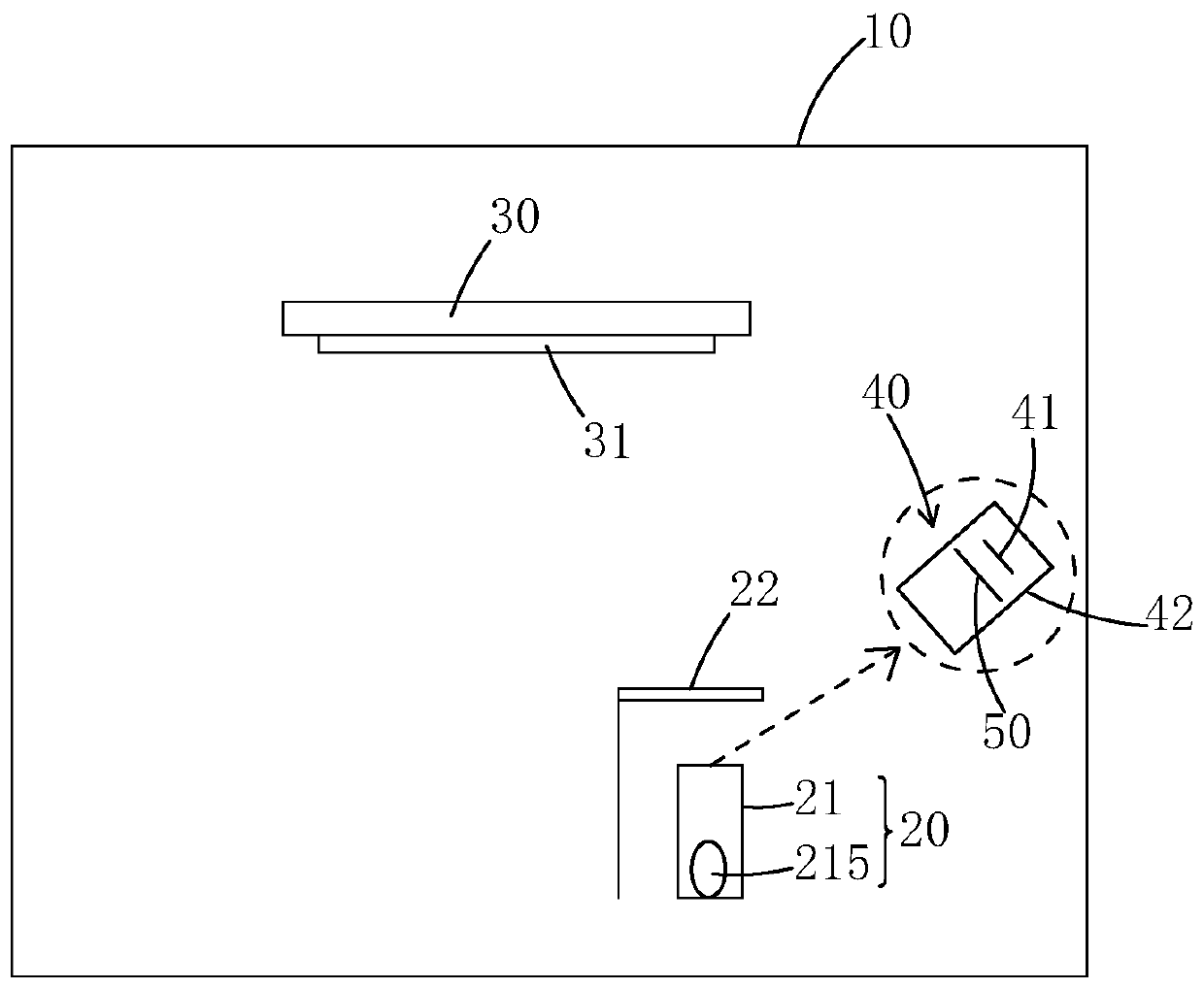

Evaporating device and evaporating method

ActiveCN107779822AAvoid depositionMonitor thicknessVacuum evaporation coatingSputtering coatingParticle physicsCrystal oscillator

The invention provides an evaporating device and an evaporating method. According to the evaporating device disclosed by the invention, a crystal oscillator sheet baffle plate is arranged between an evaporation source and a crystal oscillator sheet, and the crystal oscillator sheet baffle plate can switch between two positions, namely a position shielding the crystal oscillator sheet and a position not shielding the crystal oscillator sheet; when the crystal oscillator sheet baffle plate is in the position shielding the crystal oscillator sheet, evaporation material deposits to the crystal oscillator sheet baffle plate, so as to prevent the evaporation material from depositing to the crystal oscillator sheet; and when the crystal oscillator sheet baffle plate is in the position not shielding the crystal oscillator sheet, the evaporation material deposits to the crystal oscillator sheet. When the evaporation device disclosed by the invention is applied to an evaporation process, in theinitial stage of evaporation, namely the evaporation stage of impurities on the surface of to-be-evaporated material, the crystal oscillator sheet baffle plate is in the position shielding the crystaloscillator sheet, so as to prevent impurities from depositing to the surface of the crystal oscillator sheet; and after evaporation of the impurities on the surface of the to-be-evaporated material is completed, the crystal oscillator sheet baffle plate is in the position not shielding the crystal oscillator sheet, and the evaporation material deposits to the surface of the crystal oscillator sheet, so that an evaporation rate monitoring device acquires a steady evaporation rate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

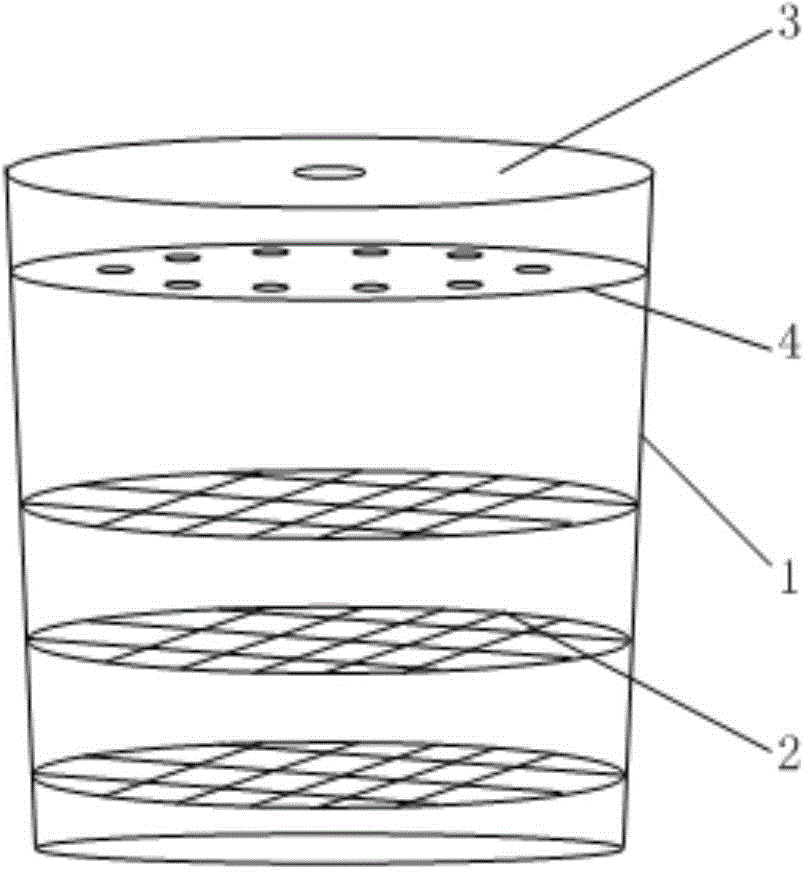

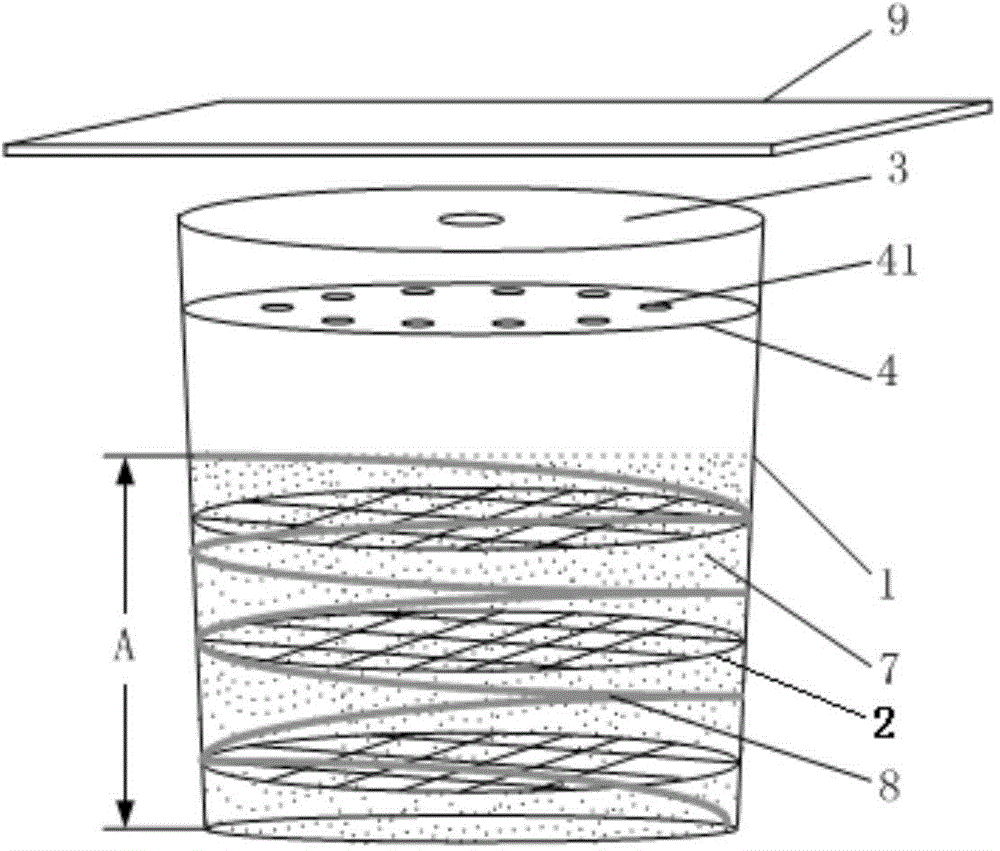

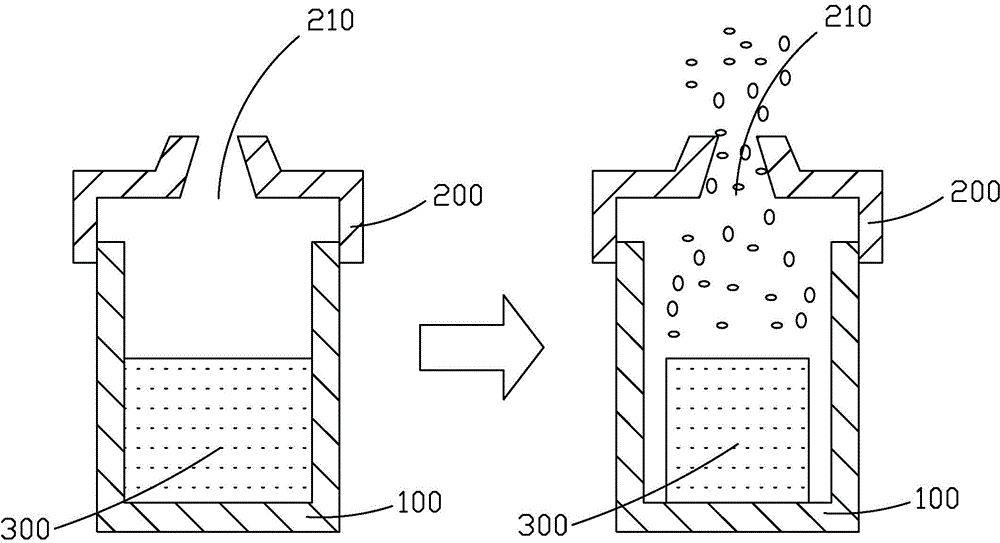

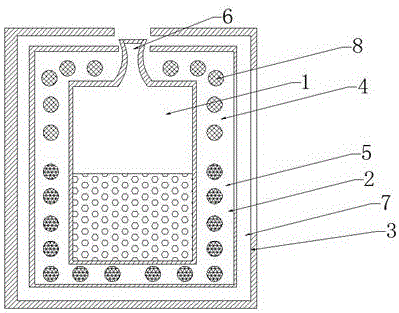

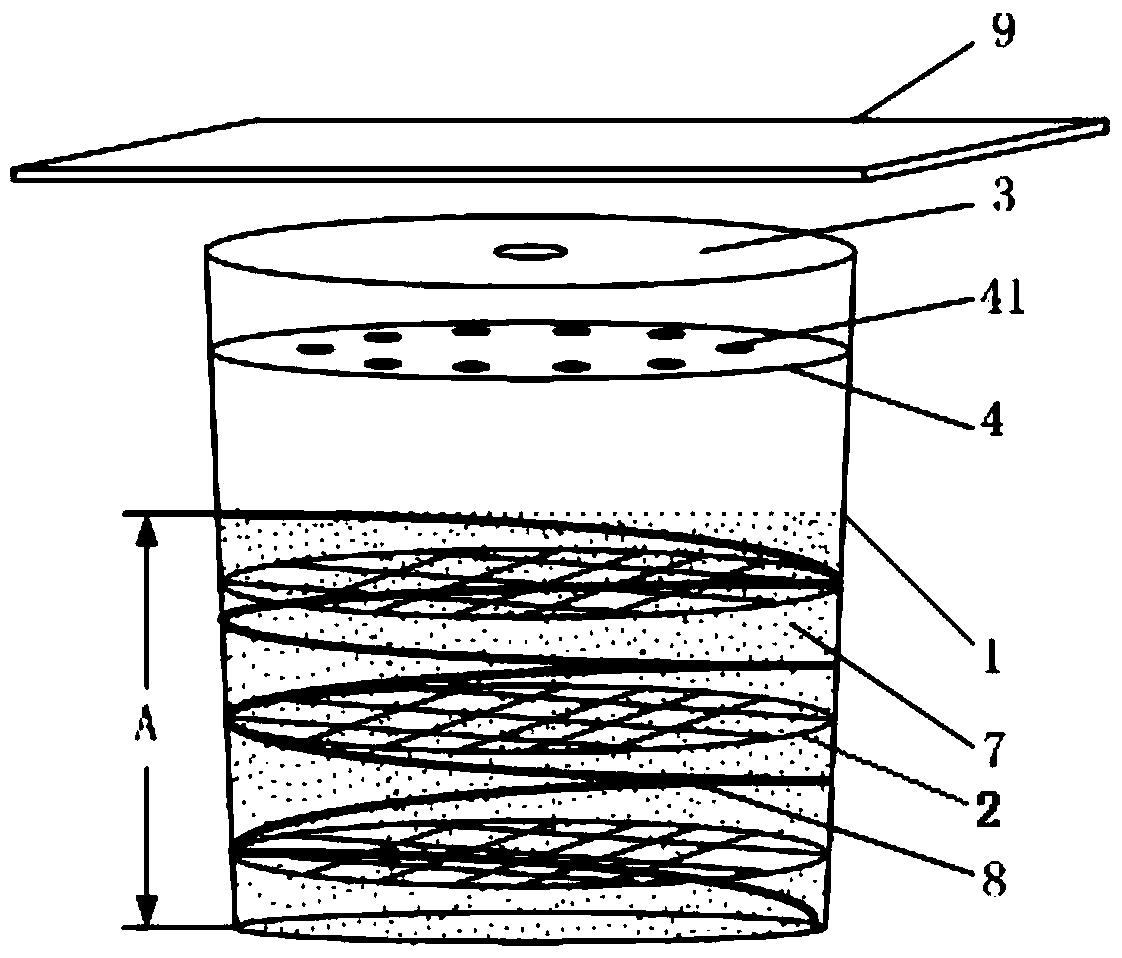

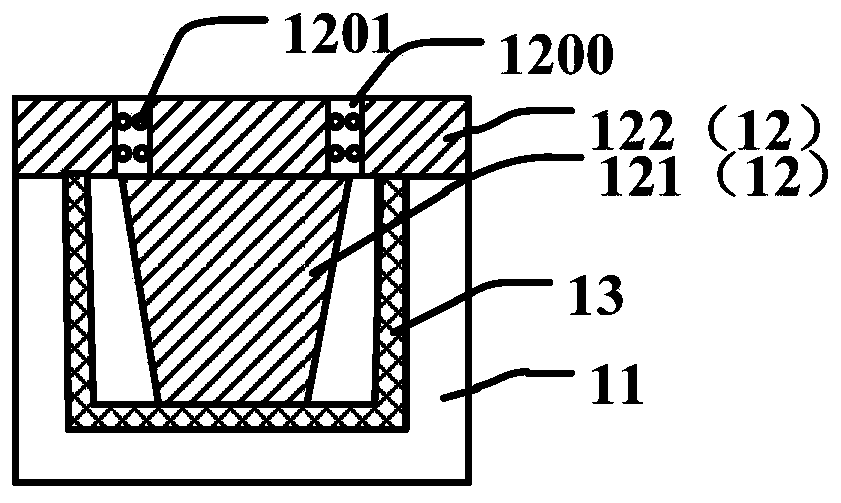

Evaporation crucible

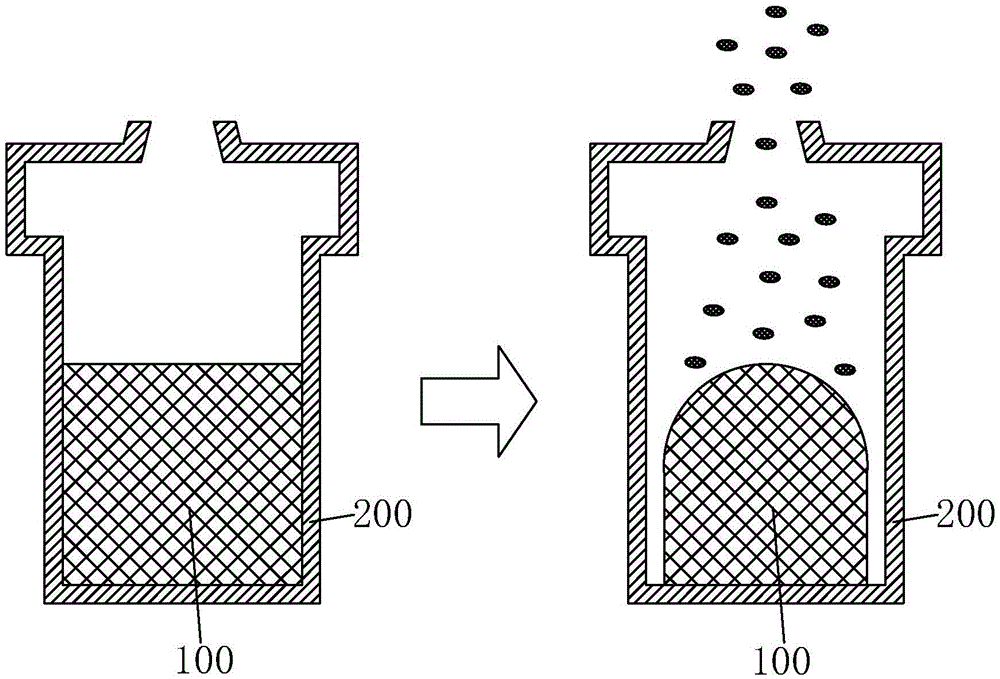

ActiveCN104928628AReduce temperature differenceEvaporation rate is stableVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention discloses an evaporation crucible, and belongs to the technical field of OLED manufacturing. The evaporation crucible comprises a crucible body and heat conduction components, wherein the heat conduction components are arranged in the crucible body and are used for directly transmitting heat on the crucible body to an evaporation material located in the middle of the crucible body. The heat conduction components are arranged in the crucible body, and the heat of the crucible body is directly transmitted to the evaporation material located in the middle of the crucible body through the heat conduction components, so that the temperature difference between the evaporation material located in the middle of the crucible body and an evaporation material close to the inner wall of the crucible body is reduced; the phenomenon that the evaporation material located in the middle of the crucible body remains and is caked to remain in the crucible body is avoided, and the utilization rate of the evaporating materials is improved; and it is ensured that the whole evaporation speed of the evaporation materials in the crucible body is stable, and the evaporation film formation effect is ensured, so that the performance of a device is ensured, and the performance of the evaporation material in the middle of the crucible body is also ensured

Owner:BOE TECH GRP CO LTD +1

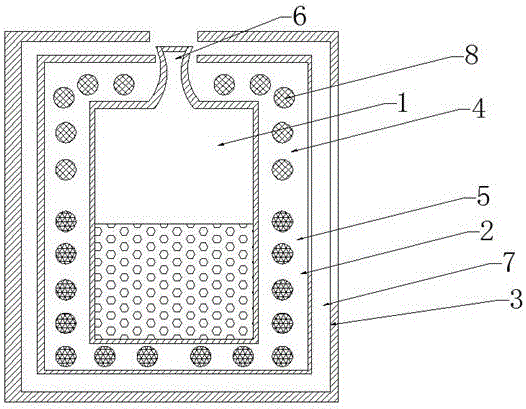

Vacuum evaporation crucible

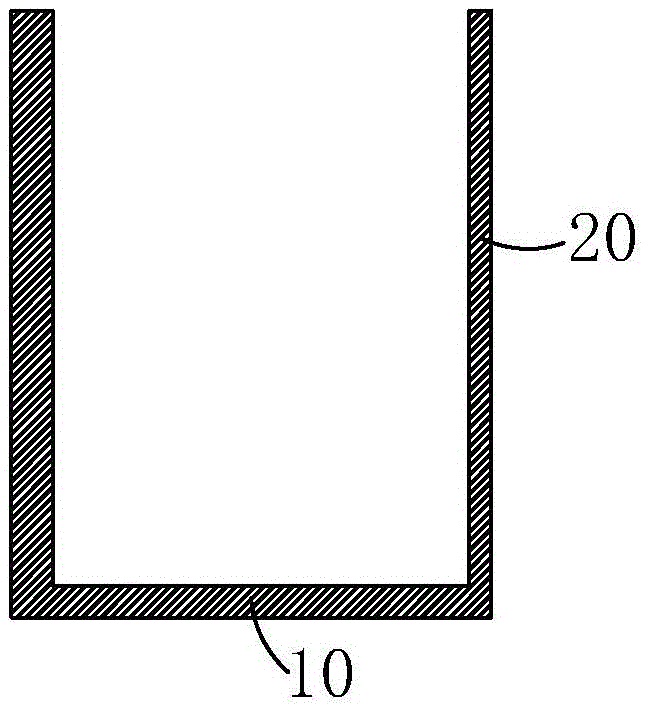

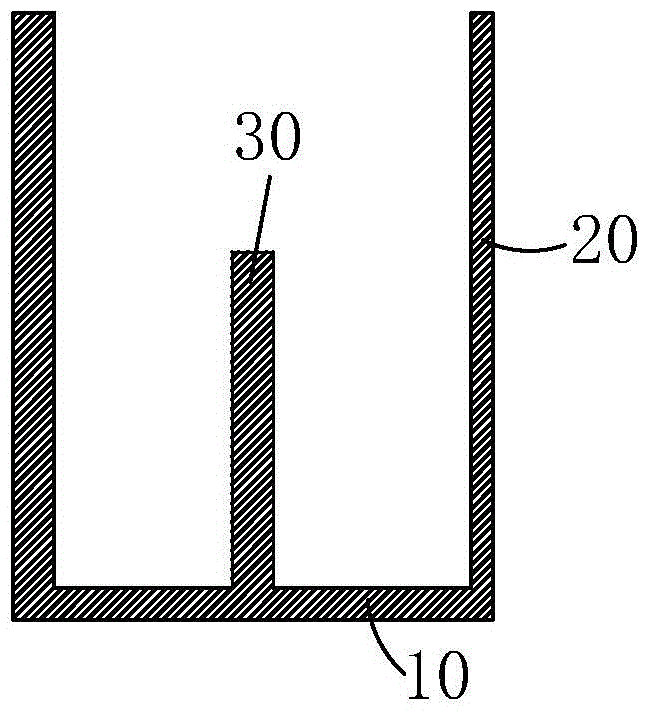

ActiveCN105648404AIncrease contact areaImprove evaporation effectVacuum evaporation coatingSputtering coatingHeat conductingCrucible

The invention provides a vacuum evaporation crucible which is obtained by machining a metal bar and removing materials. In the machining process of the metal bar, part of heat conducting structures capable of transferring heat to the middle of the crucible are reserved, for example, the contact area of a vacuum evaporation material and a crucible body is increased by increasing the inner surface area of the side wall of the crucible or additionally arranging heat conducting columns or heat conducting pieces and other heat conducting structures in the crucible, so that the vacuum evaporation material is evenly heated, the vacuum evaporation speed is constant, and the vacuum evaporation effect is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

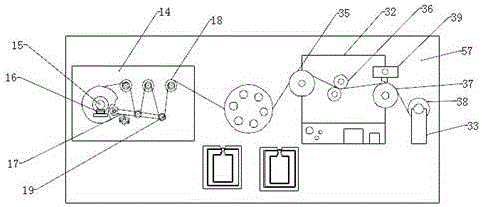

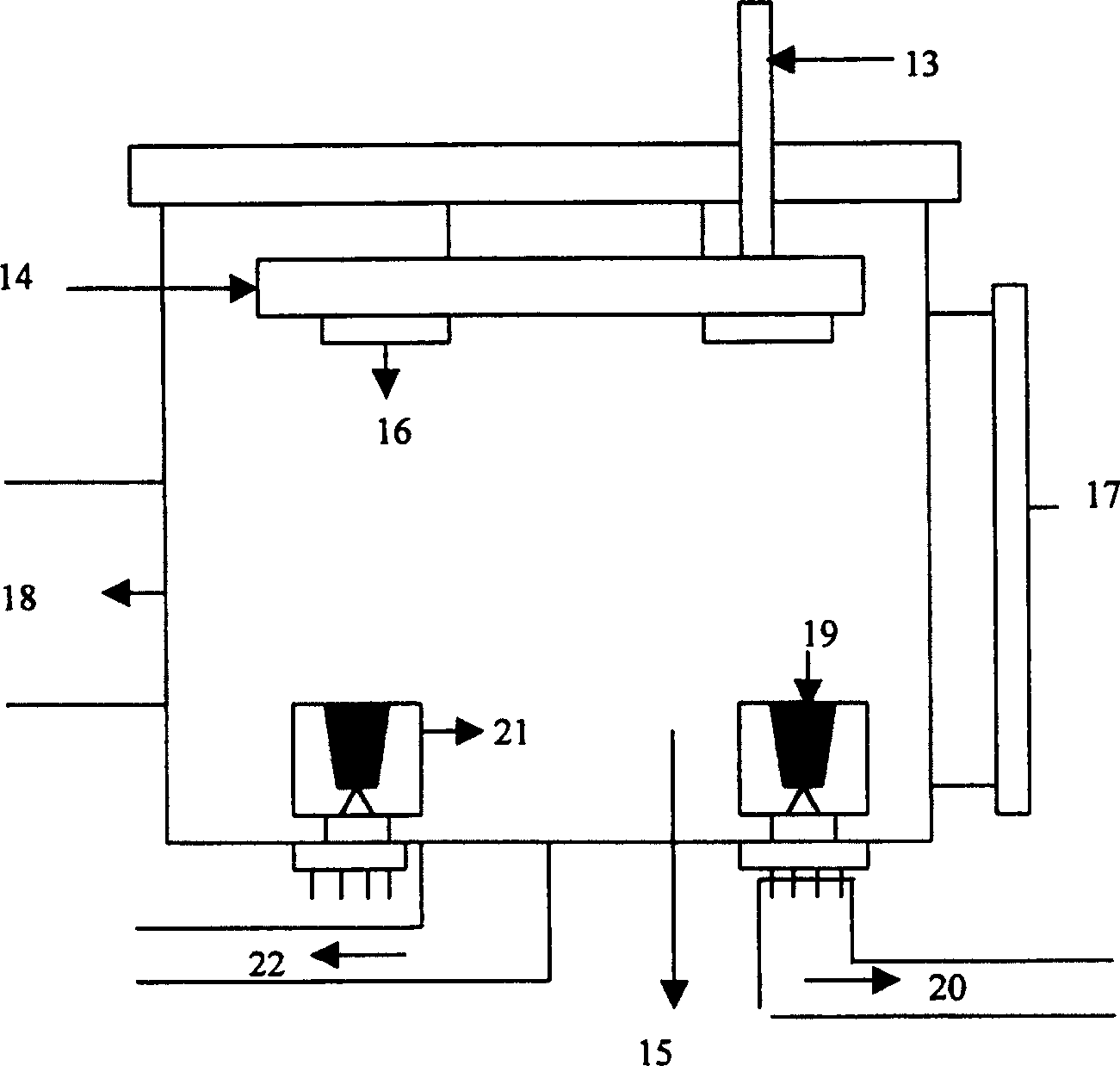

Metallized film vacuum coating device with novel evaporation crucibles

InactiveCN106244995AAvoid condensationEvaporation rate is stableVacuum evaporation coatingSputtering coatingCrucibleEngineering

The invention provides a metallized film vacuum coating device with novel evaporation crucibles. The metallized film vacuum coating device comprises a vacuum coating chamber and an evaporation drum arranged in the vacuum coating chamber. A film feeding mechanism is fixedly installed on the left side of the evaporation drum. A taking-up mechanism is fixedly installed on the right side of a cooler drum. The two evaporation crucibles are arranged below the cooler drum. Each evaporation crucible comprises a containing cavity used for containing a heated object, a heating cavity surrounding the periphery of the containing cavity, and an outer wall surrounding the heating cavity. Compared with the prior art, the metallized film vacuum coating device has the following beneficial effects that through the design of a dual-heating supply system, the temperatures of different portions of the crucibles can be controlled conveniently, the temperature of the top of each crucible is slightly higher than the material evaporation temperature, and condensation of a material can be avoided; and by accurately controlling the evaporation temperature, stability of the evaporation rate of the material is achieved.

Owner:铜陵市铜创电子科技有限公司

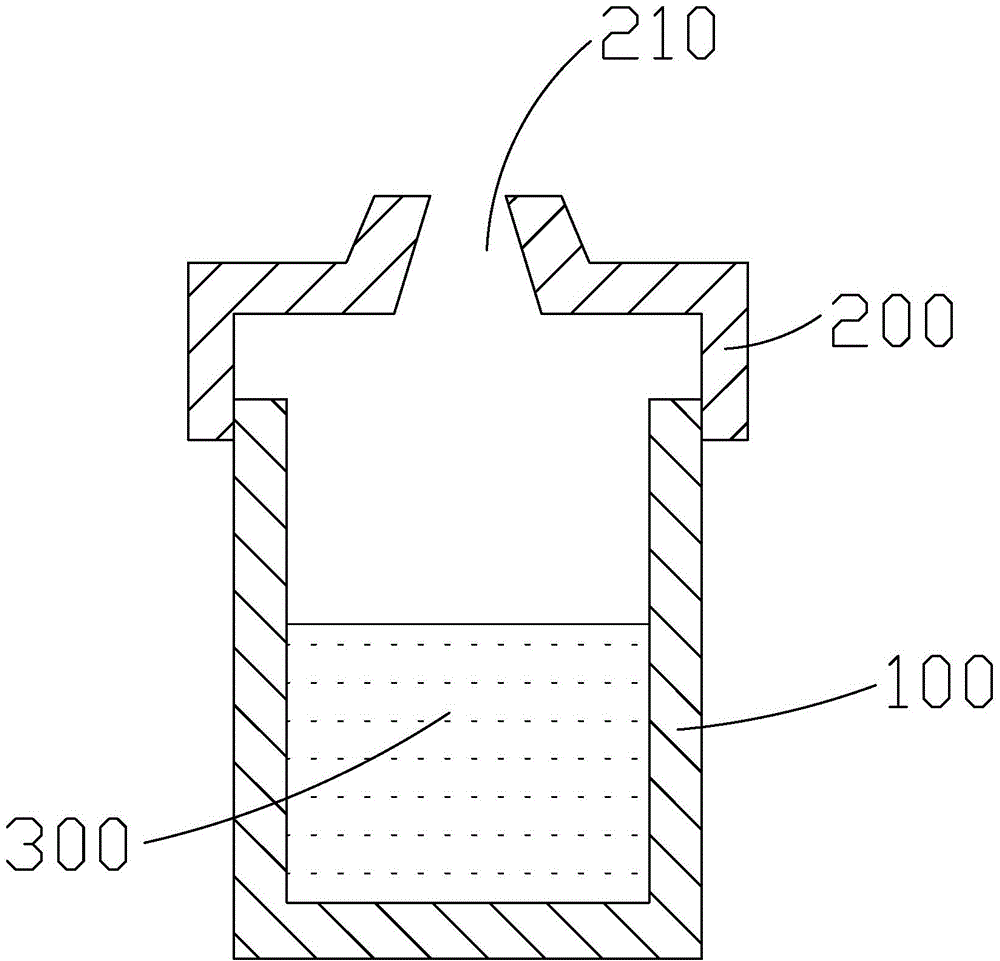

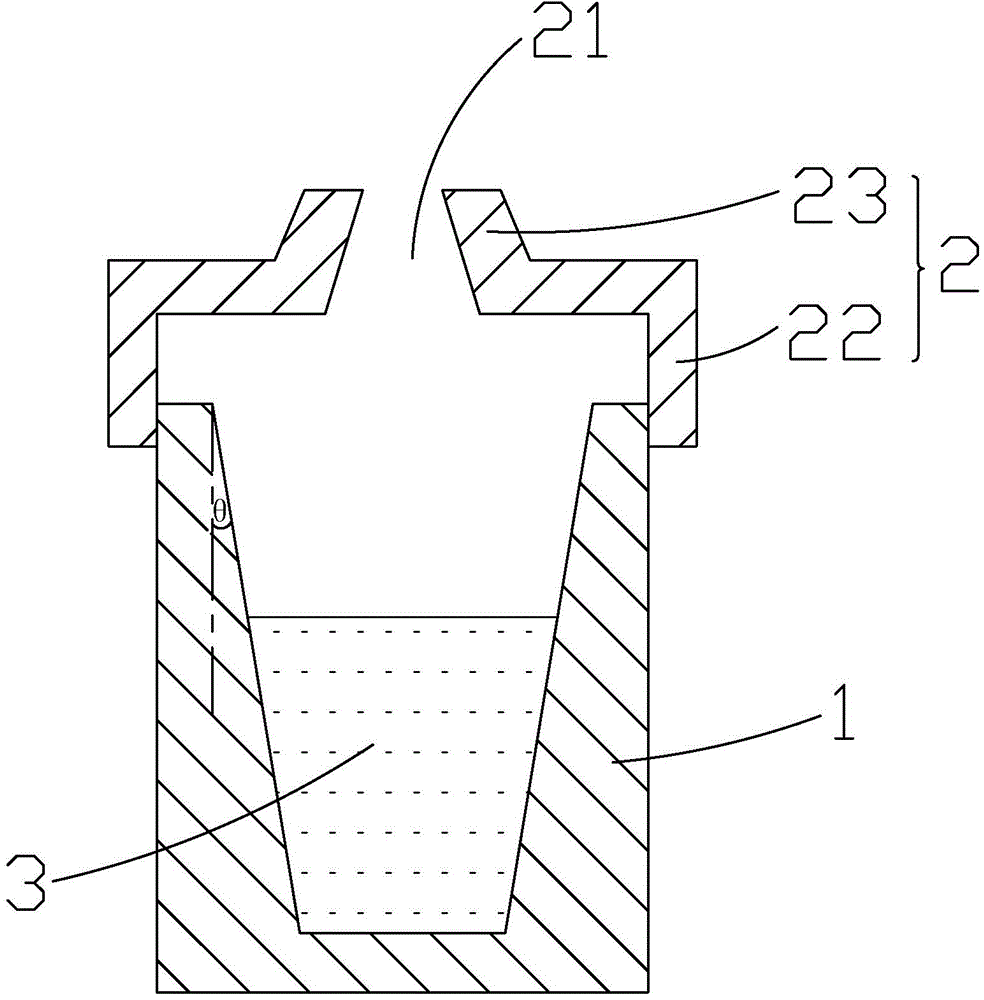

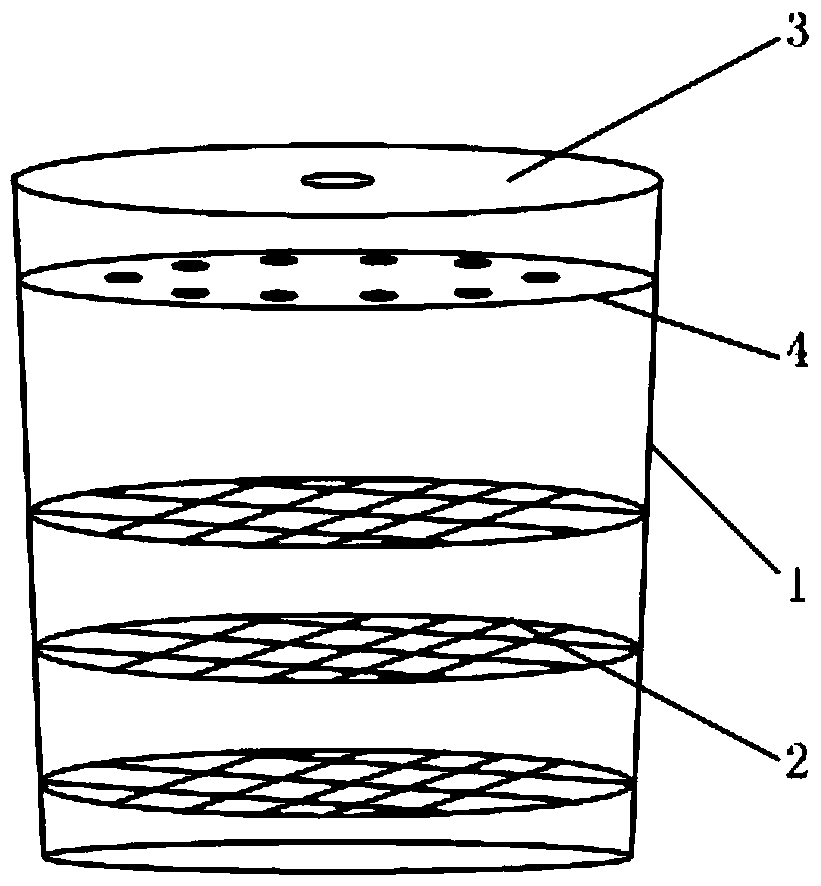

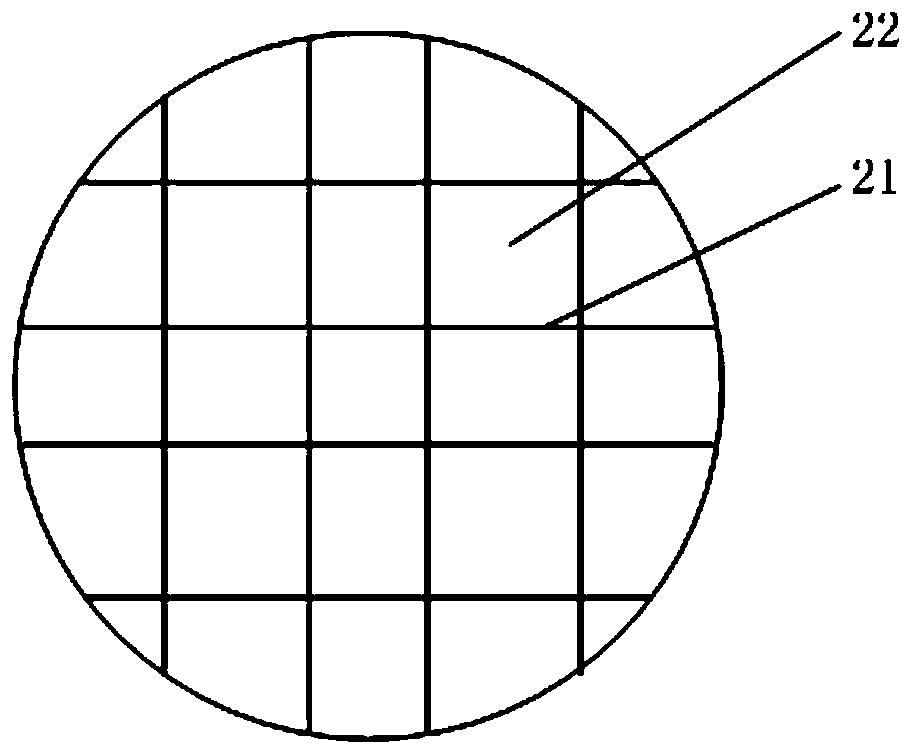

Crucible for sublimed OLED material vapor plating

ActiveCN104404450AFully contactedFully heatedVacuum evaporation coatingSputtering coatingCrucibleEngineering

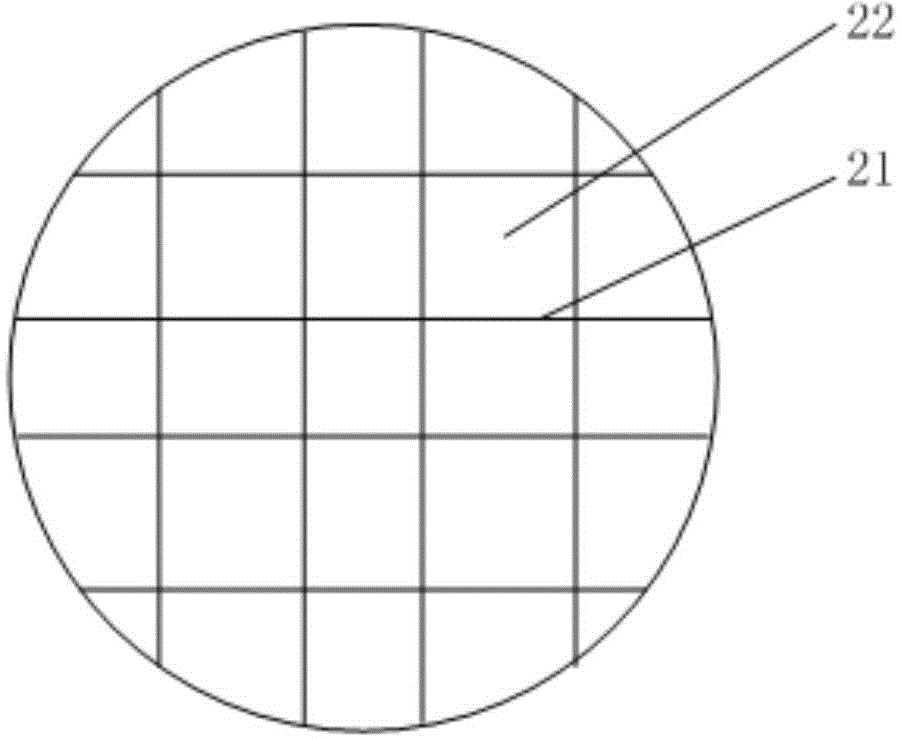

The invention provides a crucible for sublimed OLED material vapor plating. The crucible comprise a body portion (1) and an upper cover portion (2) connected with the body portion (1), the center of the top of the upper cover portion (2) is provided with an air outlet (21), the internal surface of the body portion (1) has conicity, and the internal diameter of one side of the body portion (1) close to the upper cover portion (2) is greater than the internal diameter of one side of the body portion (1) far from the upper cover portion (2). The inner wall of the crucible is designed to have certain conicity, and the OLED material residual after the OLED material is sublimated settles under the action of gravity and continuously fully contacts with the inner wall of the crucible, so heating is full, and the stability of the vapor plating rate is guaranteed.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

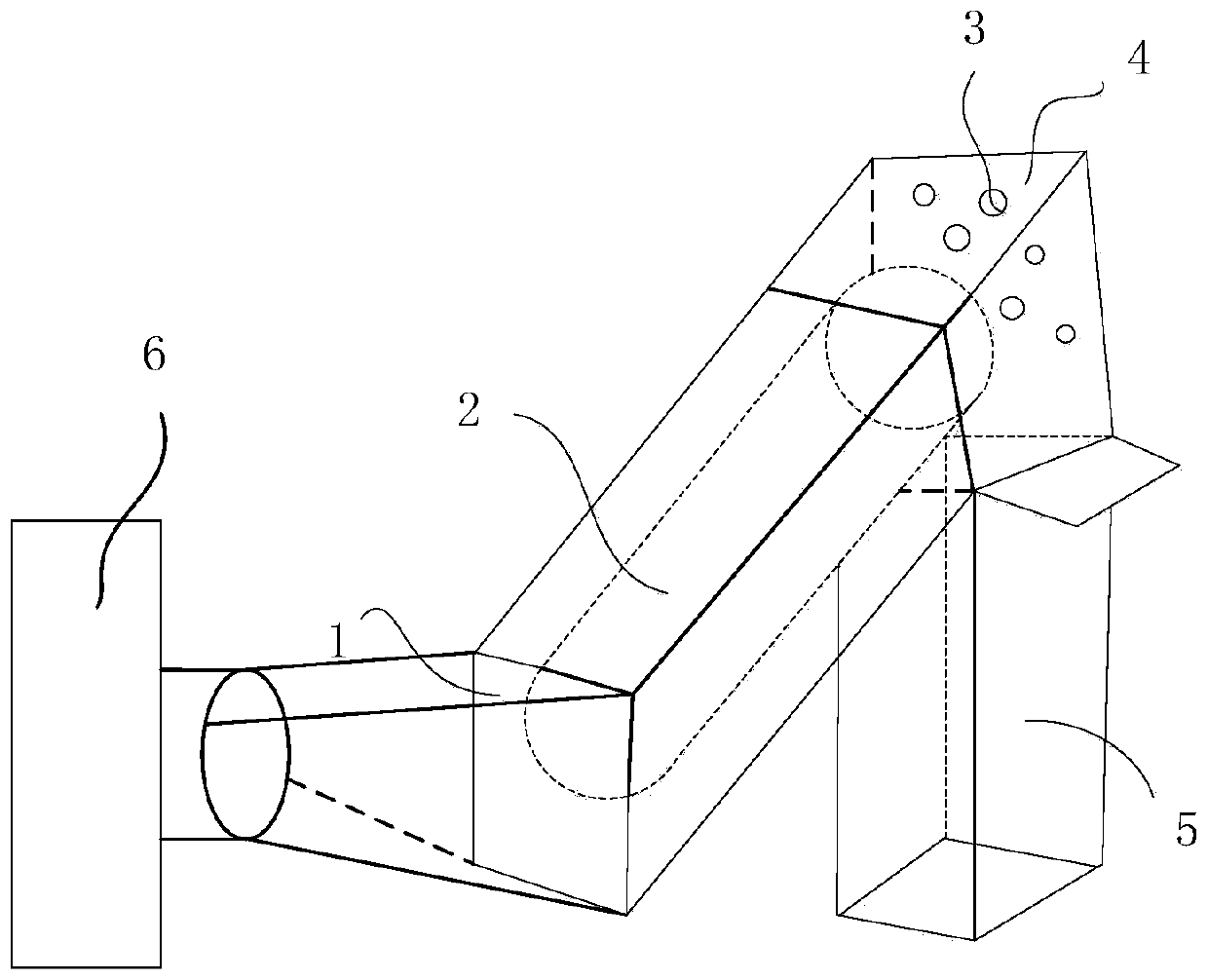

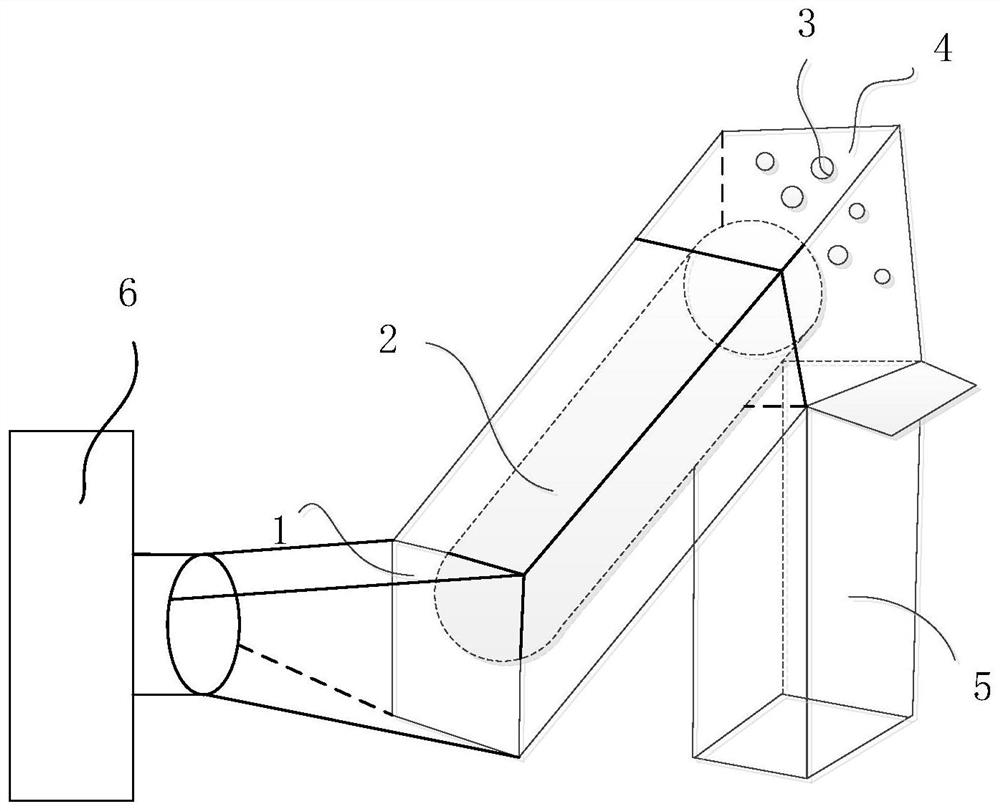

Evaporation system

ActiveCN106947941ANo residueLow costVacuum evaporation coatingSolid-state devicesEvaporationEngineering

The invention discloses an evaporation system. The evaporation system comprises a feeding device, a feed port, a discharge port, a pushing unit, an evaporation device and a storage device, wherein the feeding device includes a feeding device shell; feeding space is defined in the feeding device shell; the feed port is formed in the feeding device shell; the discharge port is formed in the feeding device shell and far from the feed port; at least one part of the pushing unit is embedded in the feeding space for pushing raw materials in the feeding space to move from the feed port to the discharge port; the evaporation device is connected with the feeding device; and the storage device is connected with the feed port of the feeding device. The evaporation system has at least one of the following advantages: the evaporation system can realize continuous feeding to improve the production efficiency; and the continuous feeding guarantees better consistency of the raw materials and no residues of the raw materials, and can keep stable evaporation speed.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

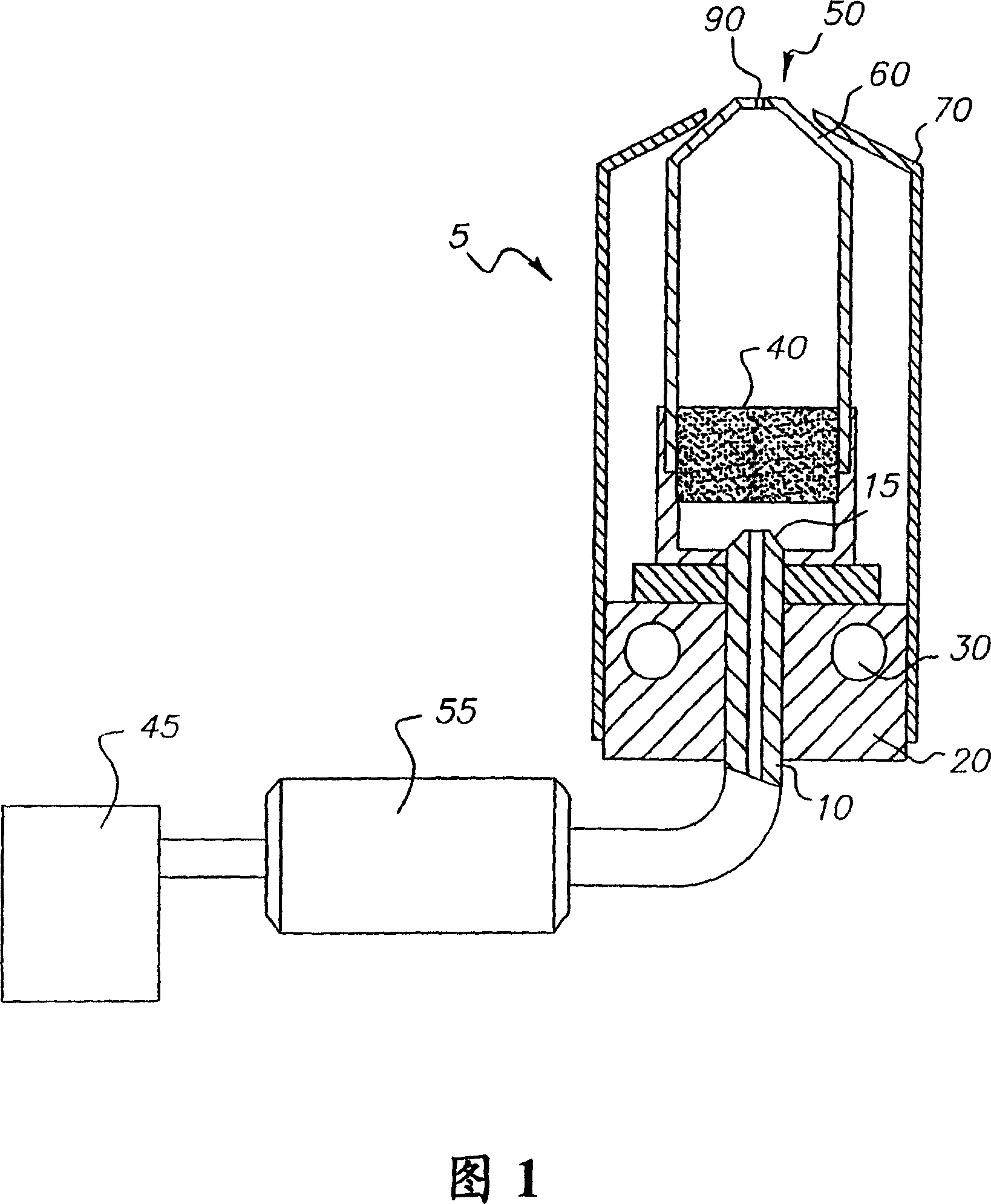

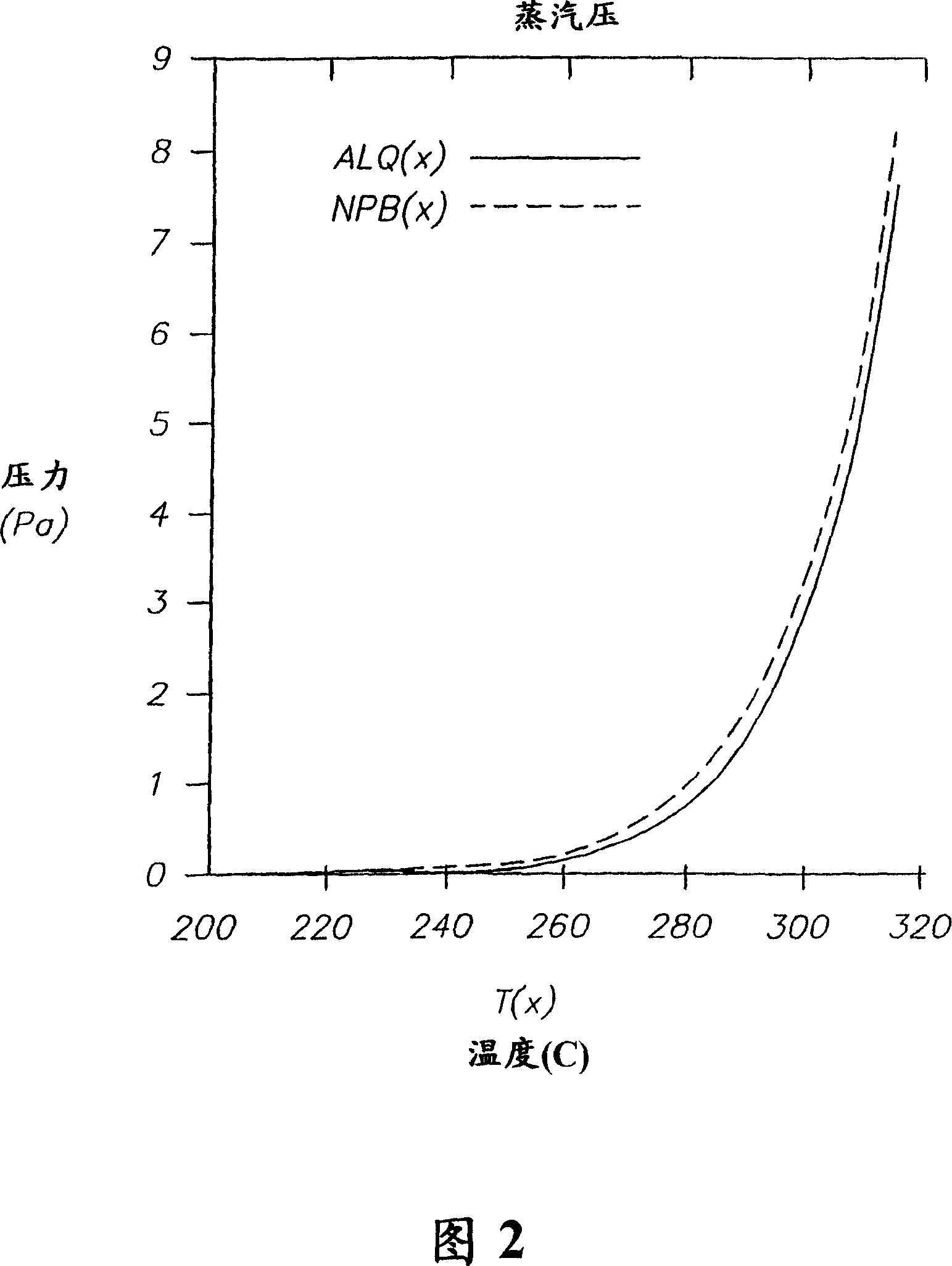

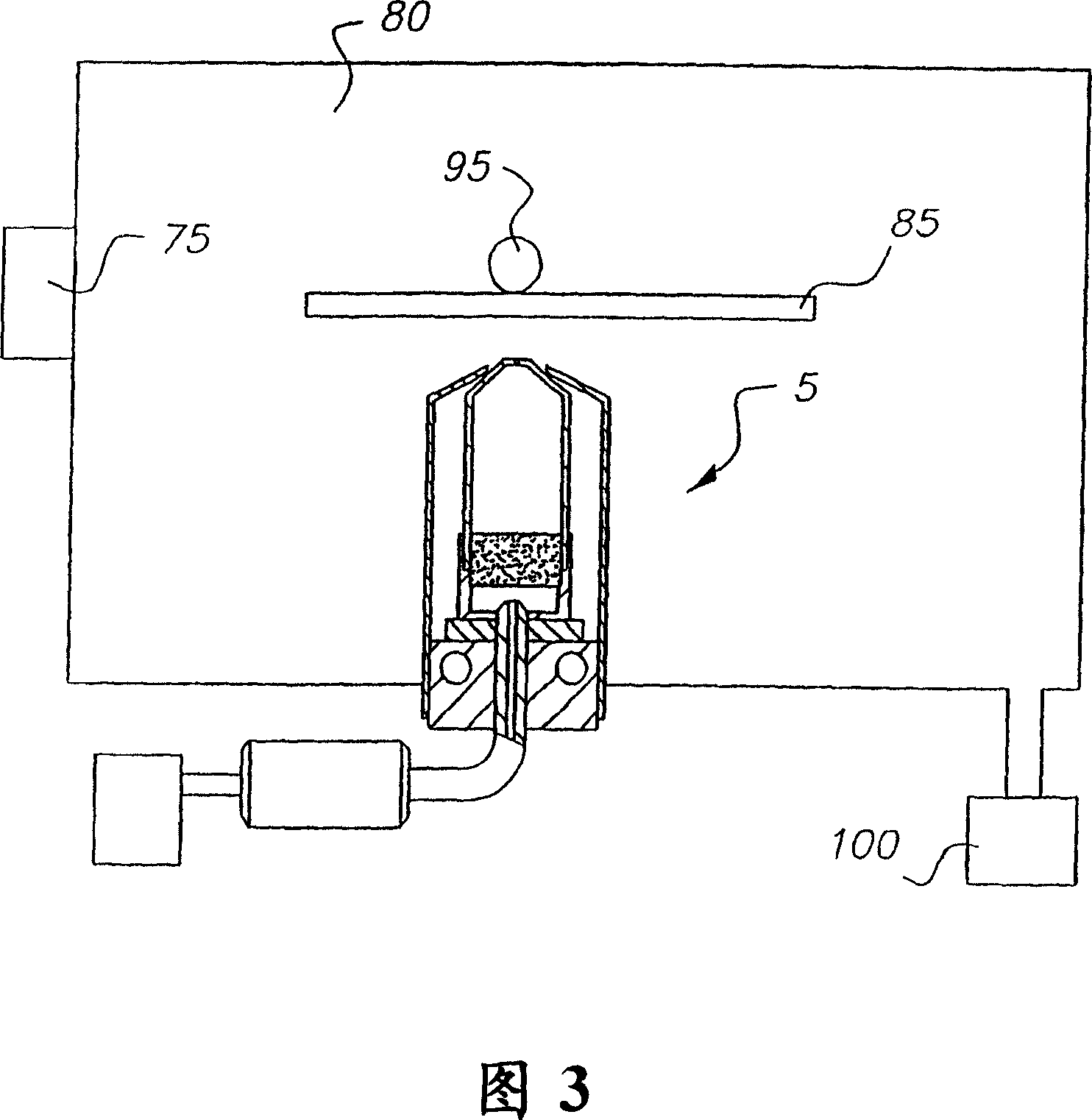

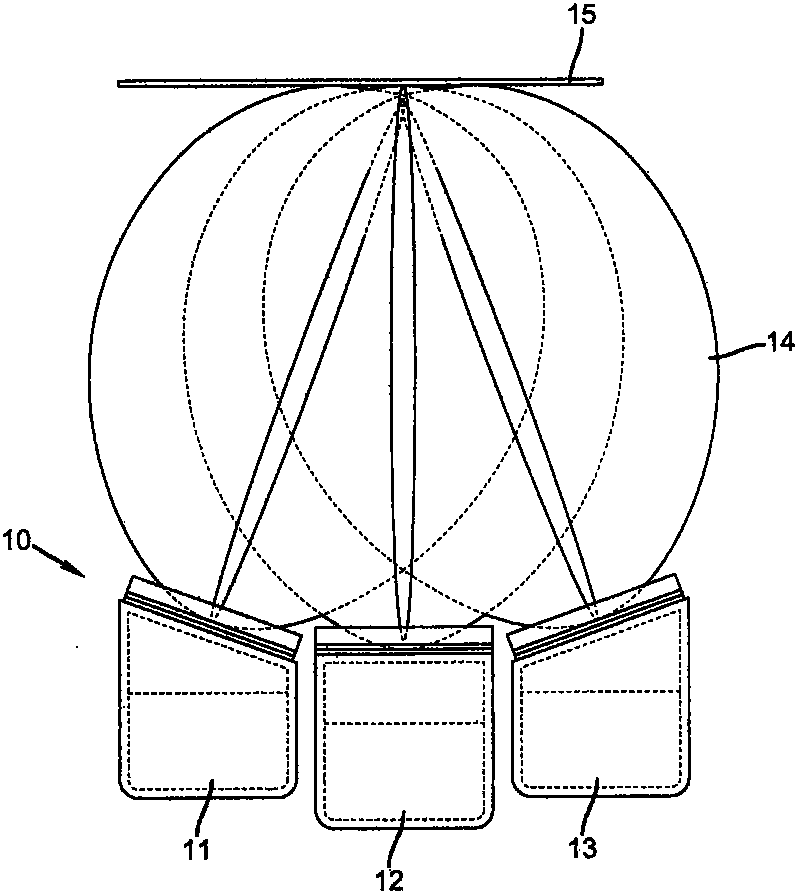

Method for vaporizing fluidized organic materials

ActiveCN1934284AReduce risk of decompositionStable temperatureVacuum evaporation coatingSputtering coatingMetallurgyOrganic matter

A method for vaporizing organic materials onto a surface, to form a film includes providing a quantity of organic material in a fluidized powdered form; metering the powdered organic material and directing a stream of such fluidized powder onto a first member; heating the first member so that as the stream of fluidized powder is vaporized; collecting the vaporized organic material in a manifold; and providing a second member formed with at least one aperture in communication with the manifold that permits the vaporized organic material to be directed onto the surface to form a film.

Owner:GLOBAL OLED TECH

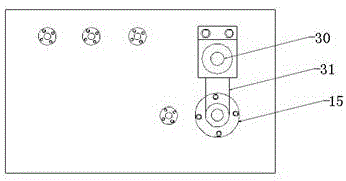

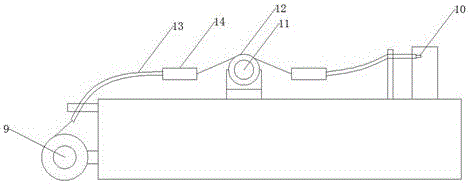

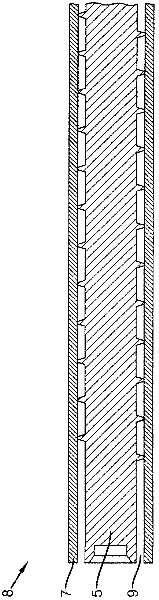

Wire feeding mechanism of vacuum film plating machine

InactiveCN106319453AAvoid damageAvoid stickingVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention provides a wire feeding mechanism of a vacuum film plating machine. The wire feeding mechanism comprises a wire supplying disc, a wire feeding mechanism body, a wire discharging nozzle and a heating crucible. The wire discharging nozzle extends into the heating crucible. The wire feeding mechanism body comprises a wire feeding rotating shaft, multiple wire feeding rolls and a power device, wherein the wire feeding rolls are fixed to the wire feeding rotating shaft; the power device provides power for the wire feeding rotating shaft; and the two ends of each wire feeding roll are provided with a wire protection sleeve and a wire pressing block. The wire feeding mechanism has the beneficial effects that the wire feeding speed of each evaporation boat is controlled through different diameters of the wire feeding rolls, thus the wire feeding amount is controlled; square resistance uniformity of a product is improved; product quality is improved; by arranging the wire pressing blocks, a metal wire in the conveying process can be located, the tail end of the aluminum wire can be constrained, and thus the tail end of the aluminum wire can be effectively prevented from sliding on a heating source; furthermore, the situation that generated aluminum chippings splash to an aluminum-plated film to damage the aluminum-plated film is prevented; and production quality of the aluminum-plated film is effectively guaranteed.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

Vacuum coating machine evaporation crucible

InactiveCN106222614AAvoid condensationEvaporation rate is stableVacuum evaporation coatingSputtering coatingCrucibleEngineering

The invention provides a vacuum coating machine evaporation crucible. The vacuum coating machine evaporation crucible comprises an accommodating cavity for accommodating heated materials, a heating cavity surrounding the periphery of the accommodating cavity and an outer wall enclosing the heating cavity; the heating cavity is sequentially provided with an upper heating unit and a lower heating unit from top to bottom, wherein the upper heating unit is used for ensuring the effect that the temperature of an evaporating opening is higher than the condensation point of evaporated materials, the temperature of the upper heating unit is controlled separately, the lower heating unit is located on the periphery of the crucible, and the temperature of the lower heating unit is controlled separately; the top of the heating cavity is provided with a runner used for allowing the heated materials to pass, and the top end of the runner is provided with an opening; the diameter of the two ends of the runner is larger than that of the middle of the runner; and the diameter of the end, provided with the opening, of the runner is smaller than the inner diameter of the accommodating cavity. The vacuum coating machine evaporation crucible has the beneficial effects that the temperatures of different parts of the crucible are convenient to control through design of two heat supply systems, the temperature of the top of the crucible is slightly higher than the evaporating temperature of the materials, and thus material condensation can be avoided; and the stability of the evaporating speed of the materials is achieved by precisely controlling the evaporating temperature.

Owner:铜陵市铜创电子科技有限公司

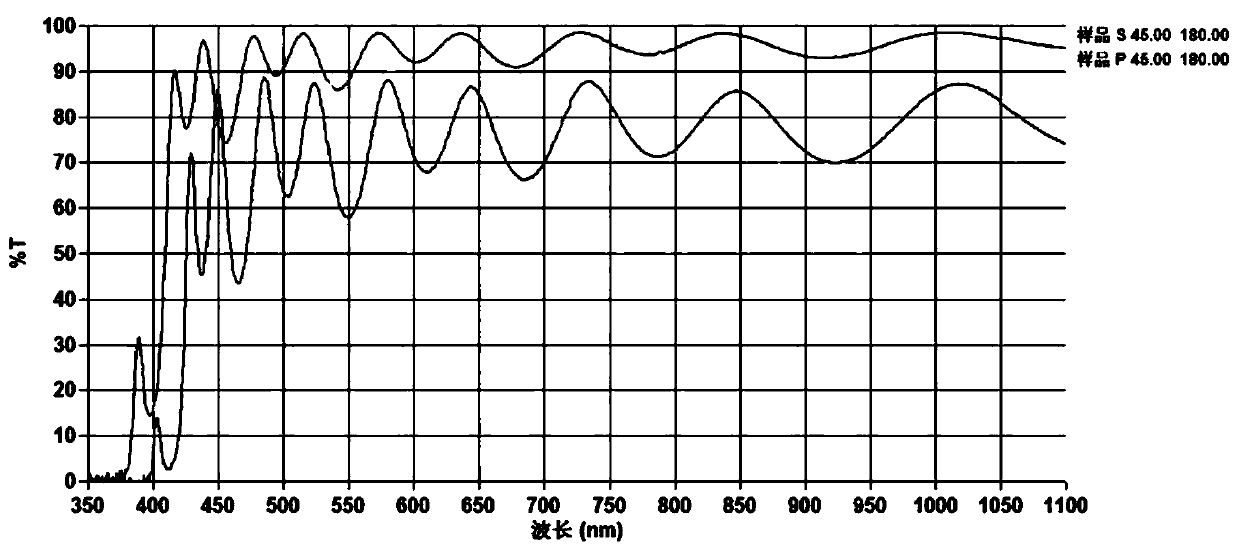

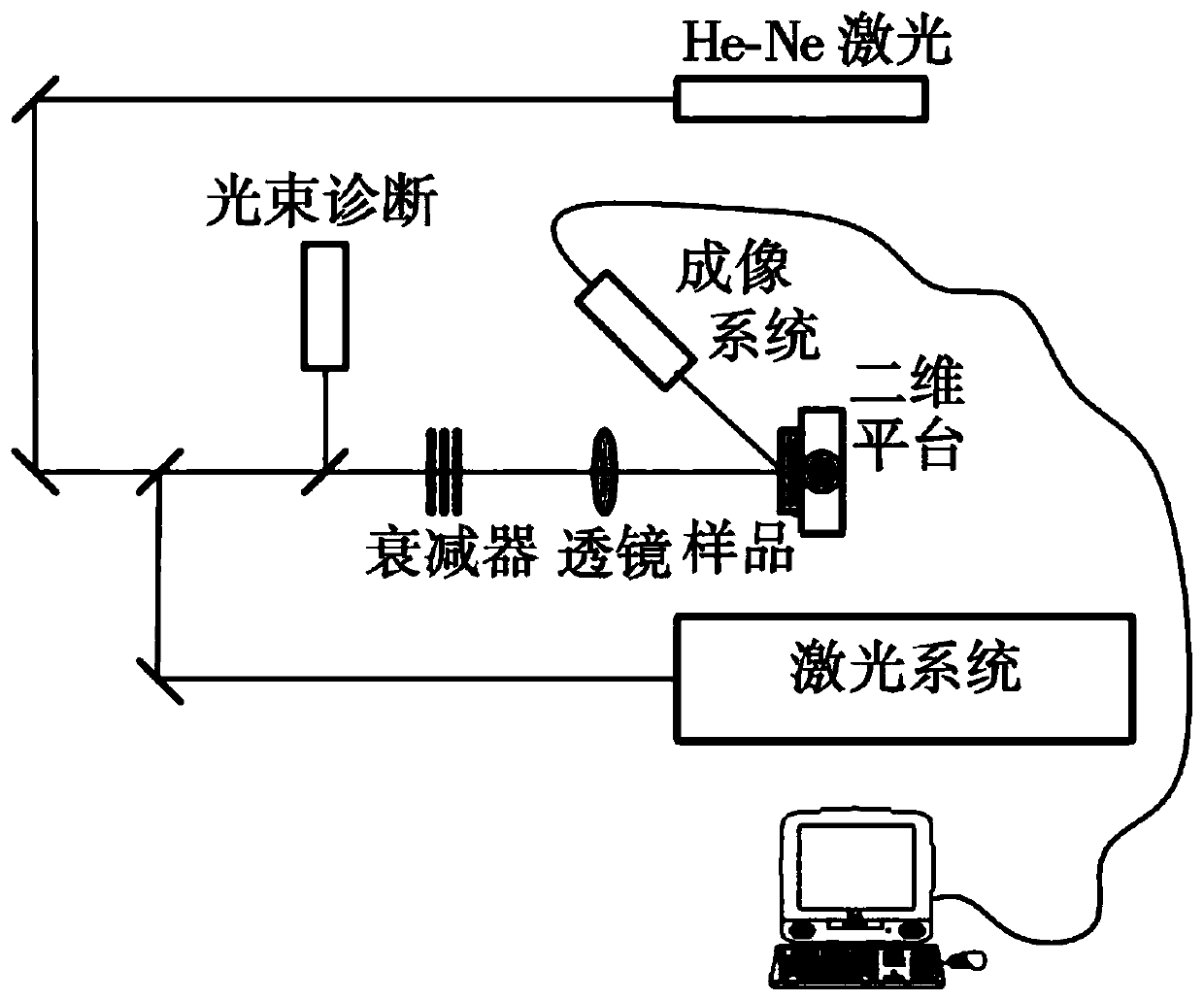

High-damage threshold laser lens and manufacturing method thereof

ActiveCN109782377AChange crystal phaseLow damage thresholdMirrorsVacuum evaporation coatingEvaporationOptical thin film

The invention belongs to the field of optical thin films, and relates to a high-damage threshold laser lens and a manufacturing method thereof. The laser lens of the invention comprises a substrate and coating layers. The coating layers alternately form multiple zirconia film layers and multiple silica film layers from the surface of the substrate, and the zirconia film layer adopts zircaloy for coating. The manufacturing method of the invention comprises steps of substrate preparation, pre-coating preparation and coating. According to the high-damage threshold laser lens capable of solving alow damage threshold by direct zirconia material evaporation and the manufacturing method thereof, the damage threshold of the zirconia film layer is raised to17J / cm<2> 10ns-coating 355 nm from 5 J / cm<2> 10ns-coating 355 nm.

Owner:湖南麓星光电科技有限公司

Crucible type evaporator source used for organic electrofluorescence type film plating machines

InactiveCN1187470CImprove insulation effectEasy to take outVacuum evaporation coatingSputtering coatingOrganic filmCrucible

A crucible-type evaporator for the machine used to plate electroluminescent organic film is composed of supporting base, temp-measuring thermocuple system, crucible, and heating furnace which consists of upper and lower No.95 ceramic rings, cylindrical quartz glass as internal shielding layer, cylindrical stainless steel as external shielding layer, and Mo wire embedded in the inner surfaces of two ceramic rings. Its advantages are long service life, good temp control, stable evaporating speed, and high thermal insulating performance.

Owner:JILIN UNIV

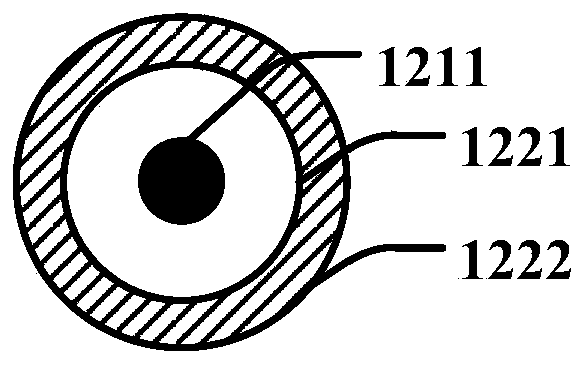

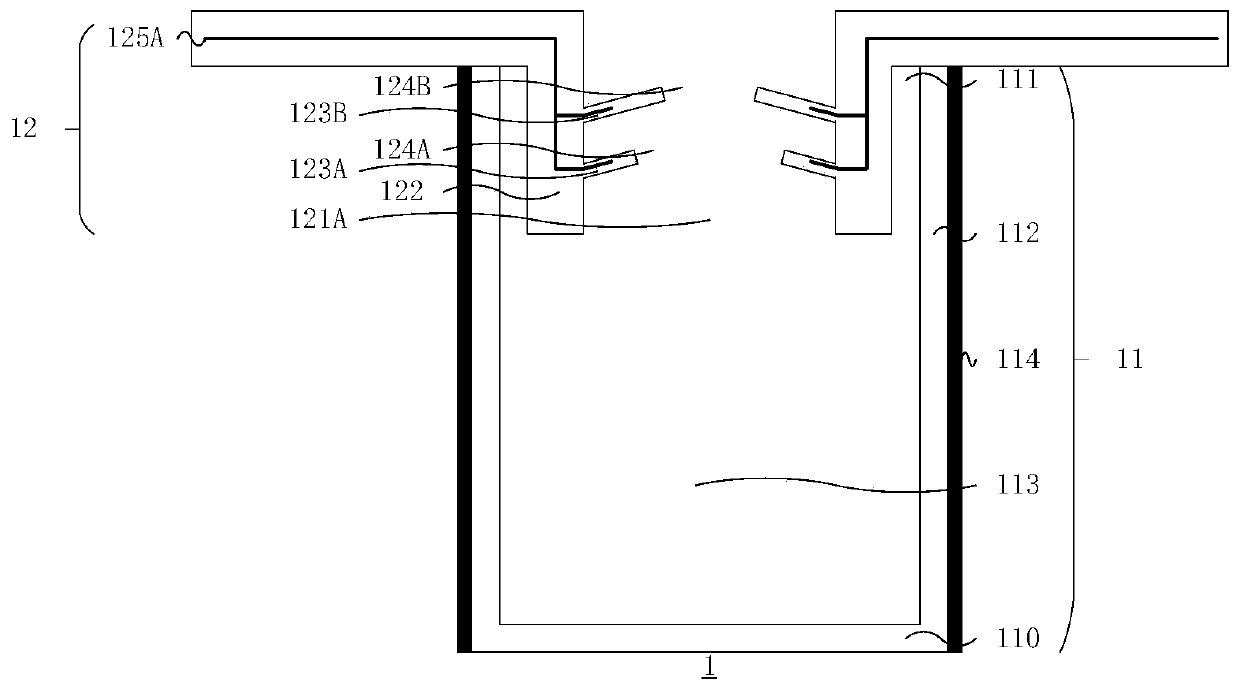

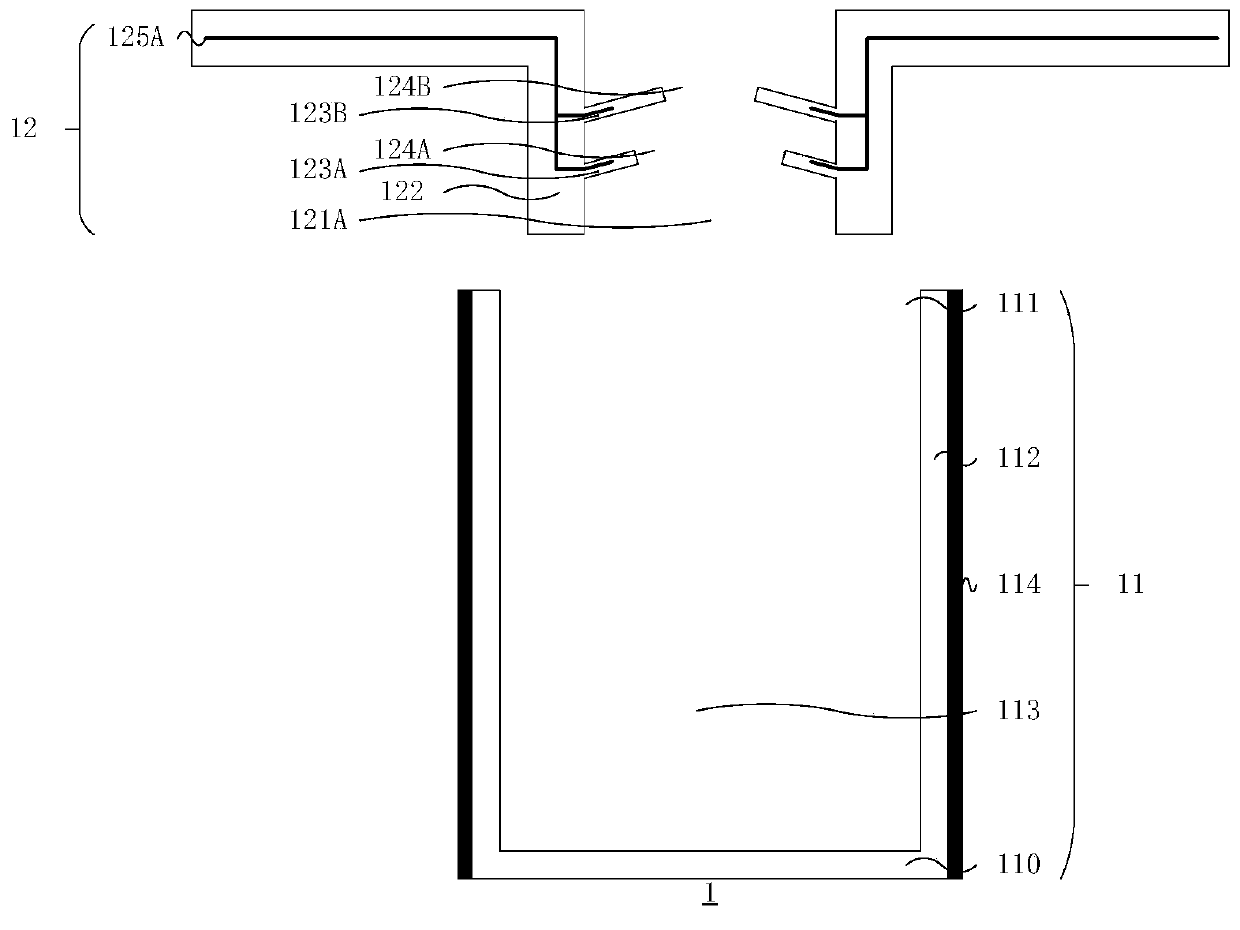

An evaporation crucible

ActiveCN104928628BReduce temperature differenceEvaporation rate is stableVacuum evaporation coatingSputtering coatingCrucibleMaterials science

The present application discloses a vapor-deposition crucible comprising a crucible body for housing a vapor-deposition material and a heat conductor inside the crucible body. At least a portion of the heat conductor extends continuously from a region proximal to an interior surface of the crucible body to a region proximal to a center axis of the crucible body.

Owner:BOE TECH GRP CO LTD +1

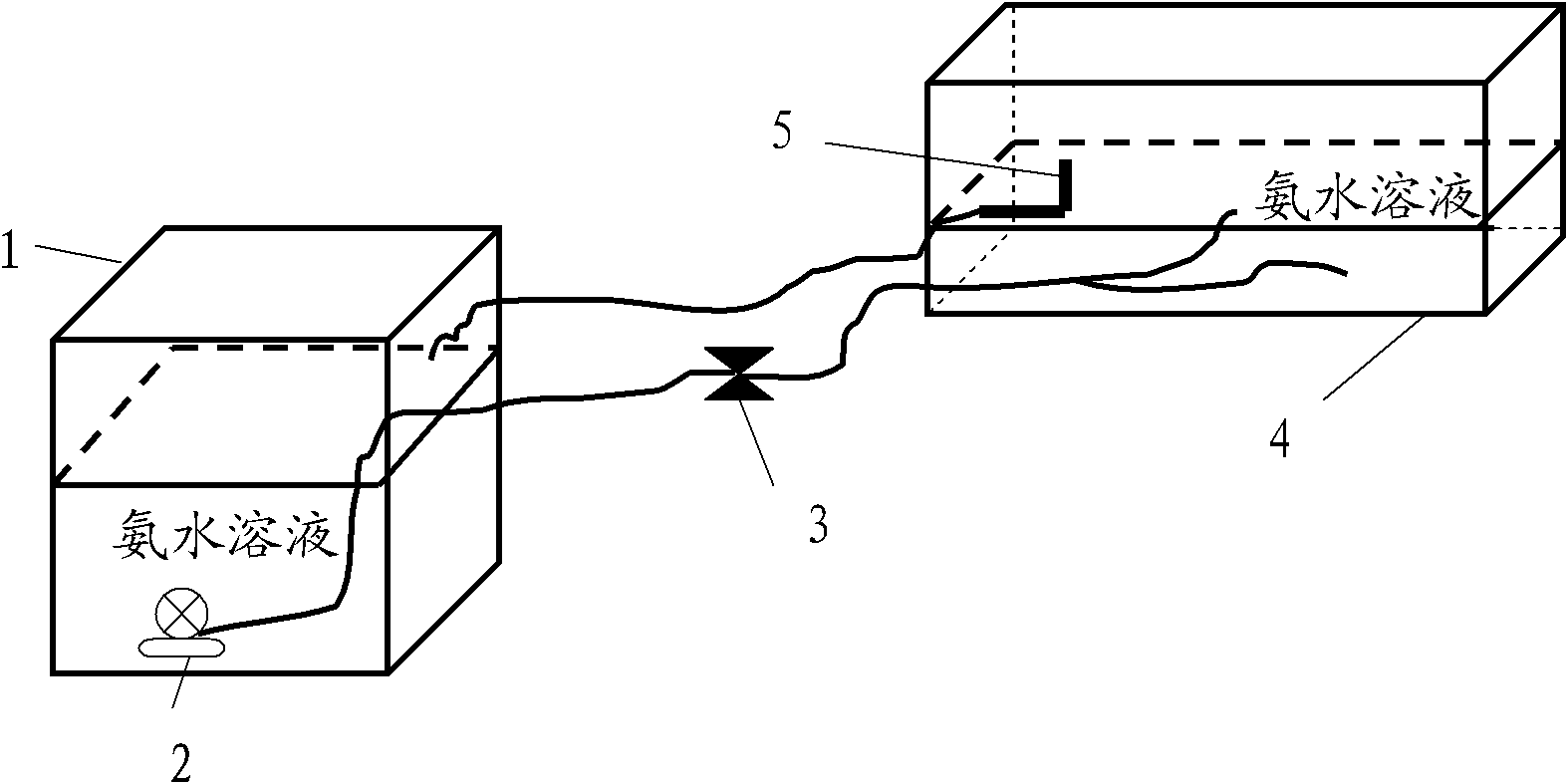

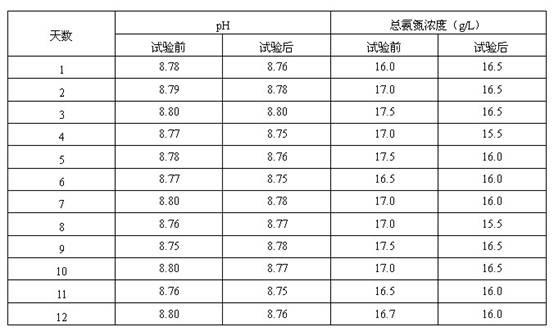

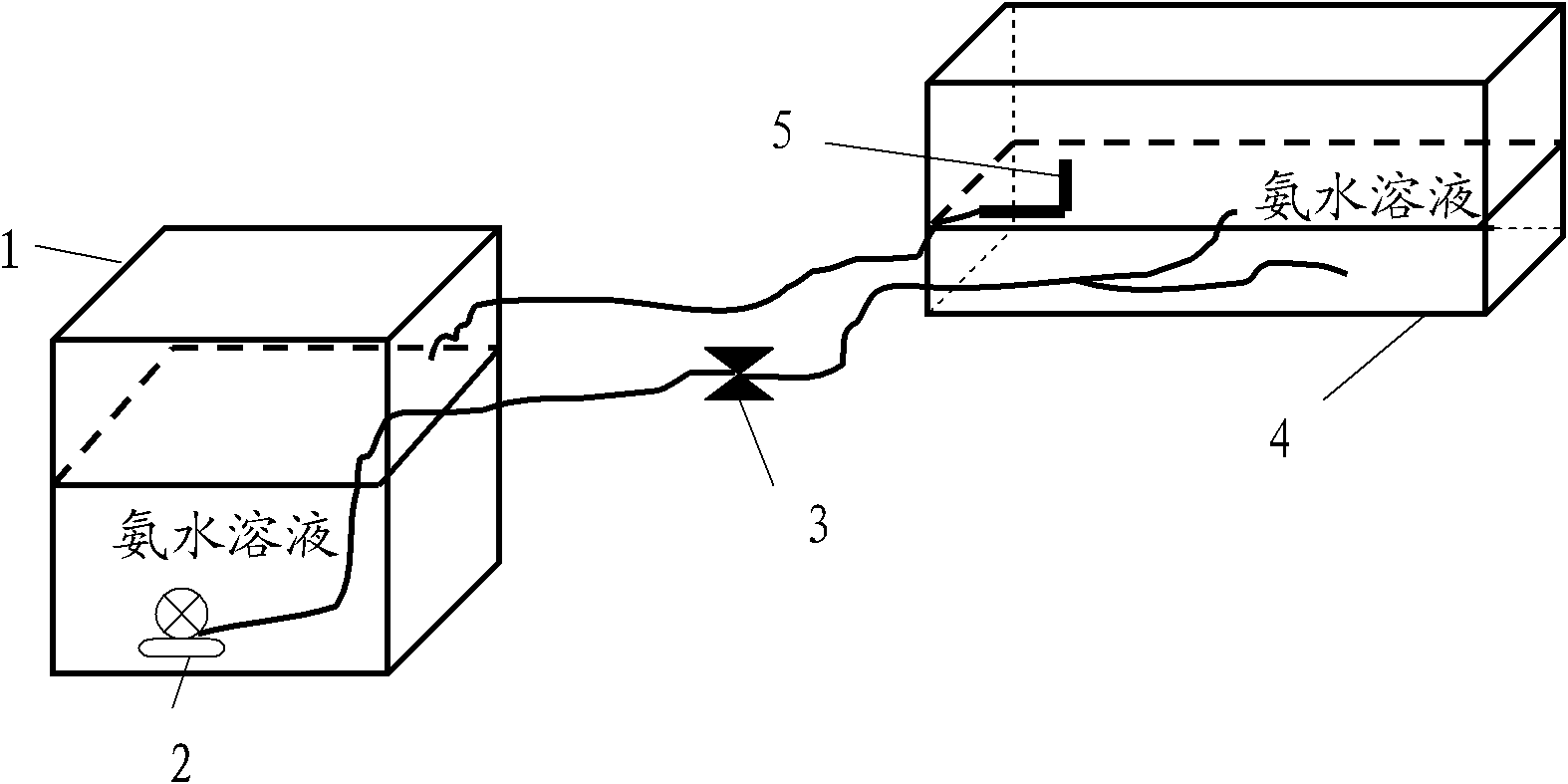

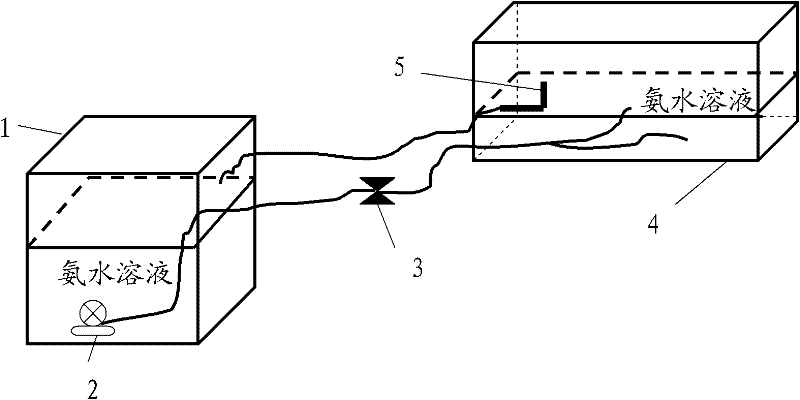

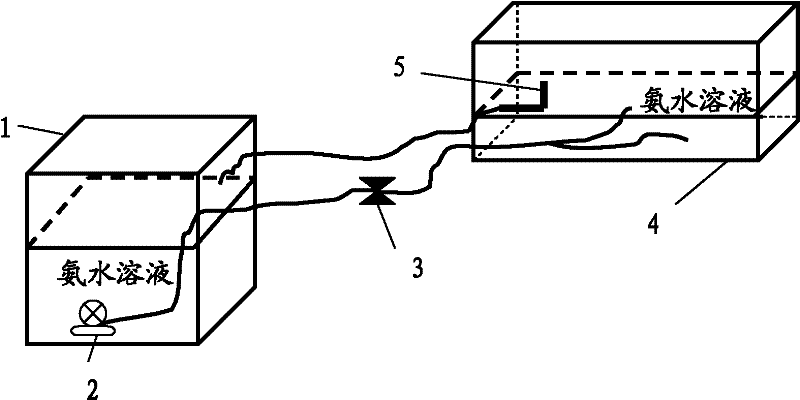

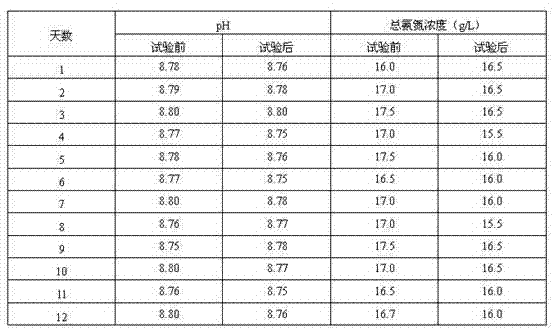

System for supplying stable liquid source for ammonia volatilization

InactiveCN102153108AEvaporation rate is stableEasy to operateAmmonia preparation/separationWater storage tankAmmonium hydroxide

The invention discloses a circulating system for supplying a stable liquid source for ammonia volatilization. A prepared ammonia solution is placed in a water storage tank; one end of a regulating valve is connected with a circulating pump arranged in the water storage tank through a first hose, and the other end of the regulating valve is connected into a test tank through a second hose; and one end of a third hose is connected into the water storage tank, the other end of the third hose is connected with the end of a right-angle copper pipe, which is parallel to the liquid level, and the end of the right-angle copper pipe, which is perpendicular to the liquid level, keeps consistent with the level of the ammonia solution. The volatilization speed of ammonia on the surface of the solution can keep stable; by using the circulating system, the characteristics such as pH value and total ammonia nitrogen concentration of the solution can keep roughly same within long time; the pH value of the solution can be regulated as required, and the operation is convenient. The circulating system provided by the invention can be used for preparing ammonia in scientific researches.

Owner:ZHEJIANG UNIV

Crucible device and evaporation device

ActiveCN111455322AEvaporation rate is stableIncrease evaporation rateVacuum evaporation coatingSputtering coatingAluminiumCrucible

The invention provides a crucible device and an evaporation device. The crucible device is used to evaporate metal aluminum materials. The crucible device comprises an outer layer crucible body and aninner layer crucible body; the outer layer crucible body is provided with an outer layer cavity whose surface is covered with a heat reflective coating; and the inner layer crucible body is providedwith a body part nested in the outer layer cavity of the outer layer crucible body. On the one hand, by arranging the heat reflective coating on the inner wall of the outer layer crucible body, the evaporation material in the crucible device can maintain a stable vaporization rate, and the evaporation rate is effectively increased; and on the other hand, grooves are formed in the upper part of theinner layer crucible body, and the grooves are provided with overflow holes which can be used to channel overflow liquid to the outer layer crucible body, so that the risk of liquid emerging from theupper surface of the crucible device and damaging the crucible device is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

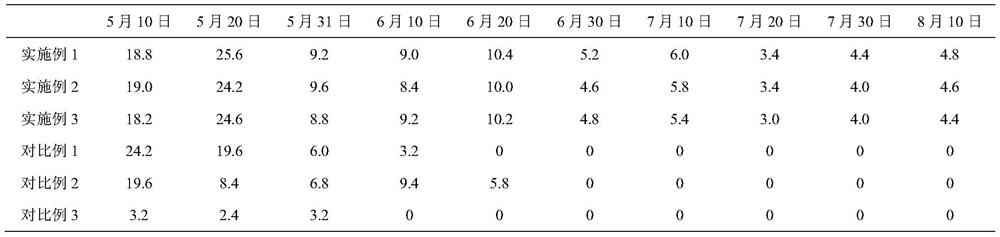

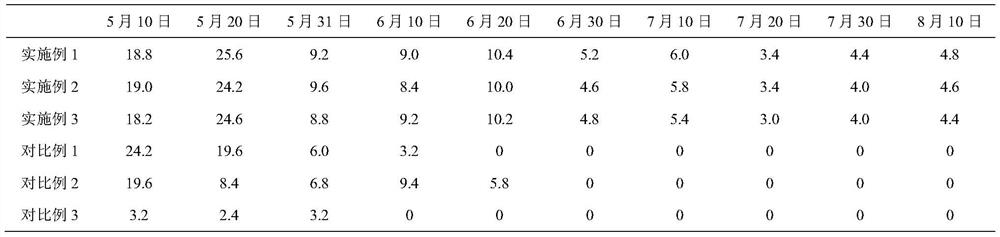

Attractant sustained-release microcapsule for Xylosandrus crassiusculus as well as preparation method and application thereof

ActiveCN113841693AProlong the evaporation timeEvaporation rate is stableBiocidePest attractantsPolyvinyl alcoholZoology

The invention discloses an attractant sustained-release microcapsule for Xylosandrus crassiusculus as well as a preparation method and application thereof. The capsule comprises a wall material and a core material, wherein the wall material is prepared from 2-methyl-2-methyl acrylate, 2-methyl-2-acrylic acid and dibenzoyl peroxide; the core material is prepared from Xylosandrus crassiusculus pheromone Conophthorin, normal hexane and paraffin; and polyvinyl alcohol is added into the wall material and the core material for emulsification to obtain the sustained-release microcapsule. The capsule is installed in a trapping and killing device and is used for trapping and killing the Xylosandrus crassiusculus, so that breeding of the Xylosandrus crassiusculus is stopped or reduced, and the purpose of protecting host plants is achieved.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

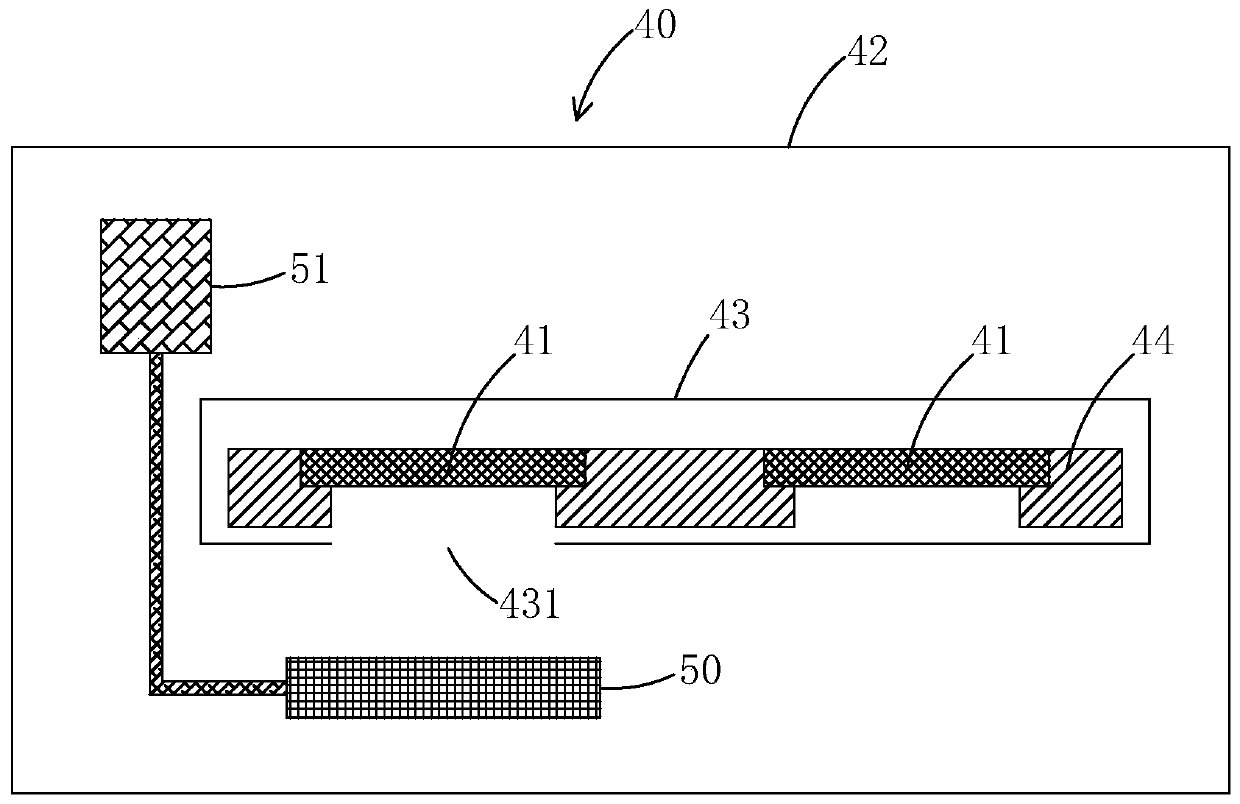

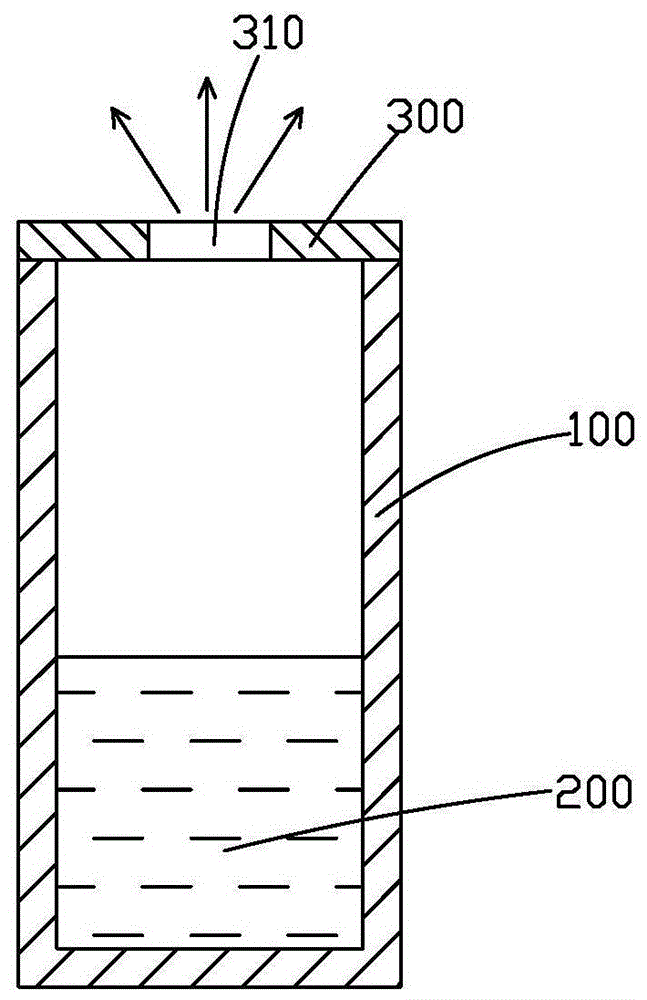

Evaporating cavity lining device, evaporating system thereof and evaporating device

ActiveCN110284108AGuaranteed evaporation rate stabilityReduce loss costsVacuum evaporation coatingSputtering coatingMechanical engineeringSemiconductor

The invention relates to the technical field of semiconductor technology, in particular to an evaporating cavity lining device, an evaporating system thereof and an evaporating device. The evaporating cavity lining device comprises a cavity assembly, wherein the cavity assembly comprises a first shell and a second shell; the first shell is provided with a first opening end and a second opening end arranged oppositely; the first opening end is externally connected with the evaporating device; a steam passage allowing steam to circulate is formed in the first shell; the second shell communicates with the second opening end; and a material storing area for storing the steam from the steam passage is formed in the second shell. The evaporating cavity lining device can ensure that the evaporating device warms organic material in advance, and the situation that the evaporated material enters an evaporating area to interfere with a base plate is avoided.

Owner:SUZHOU QUINGYUE OPTOELECTRONICS TECH CO LTD

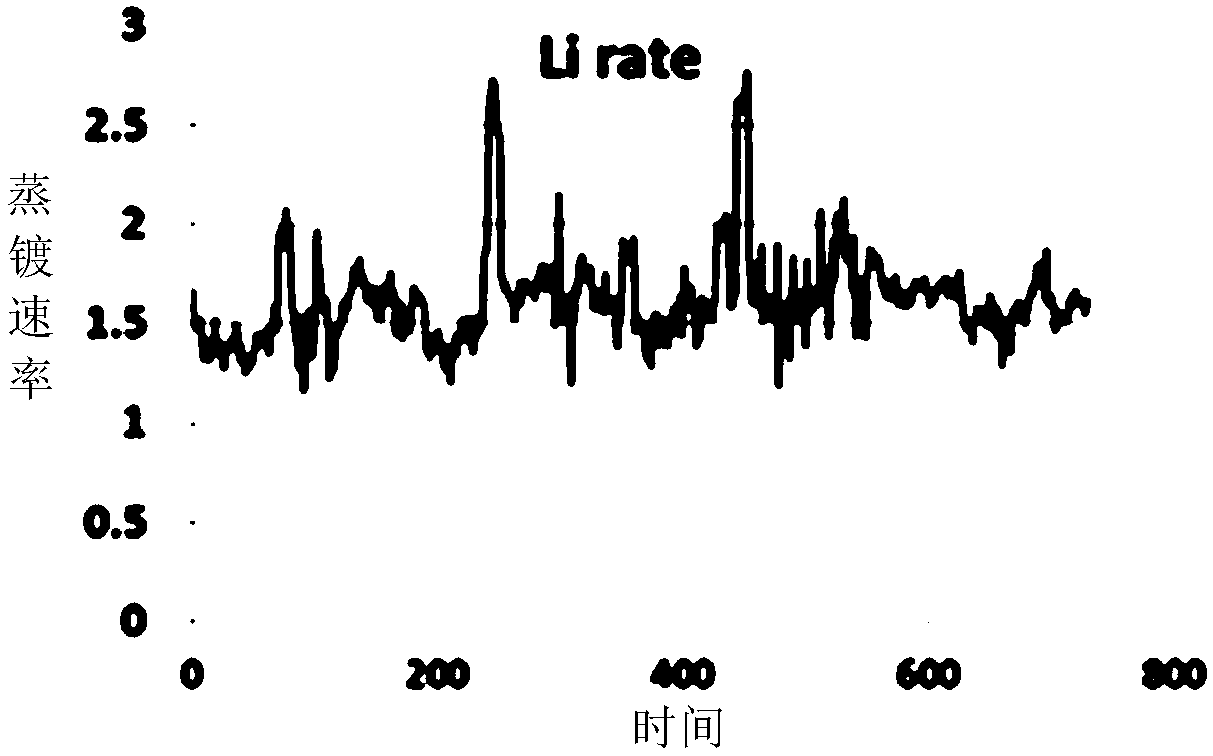

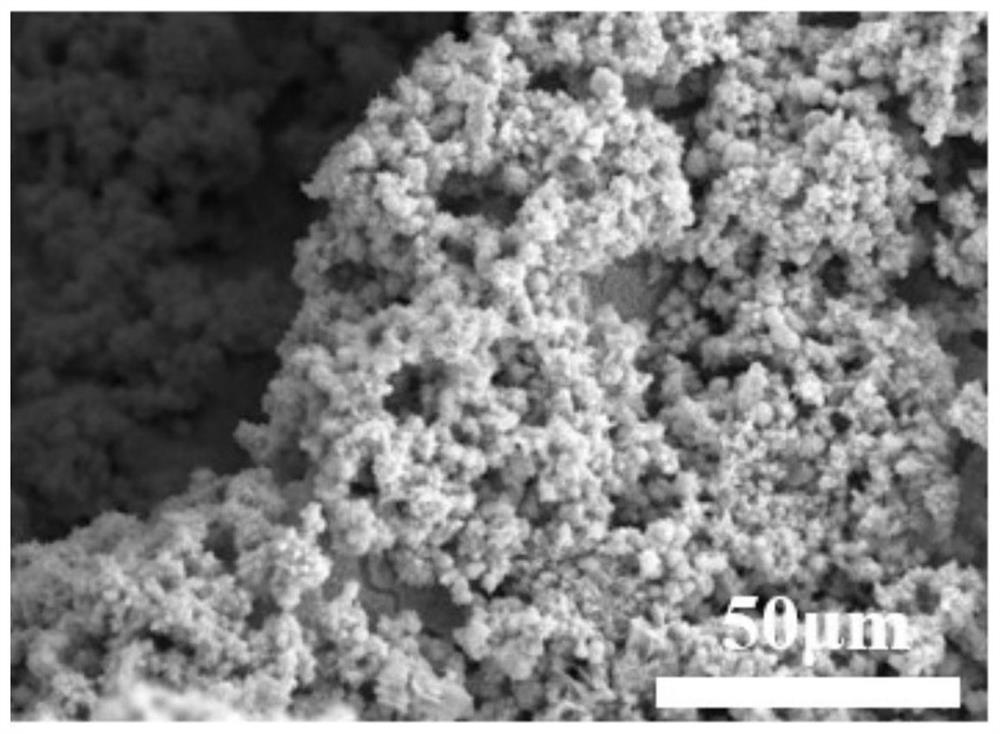

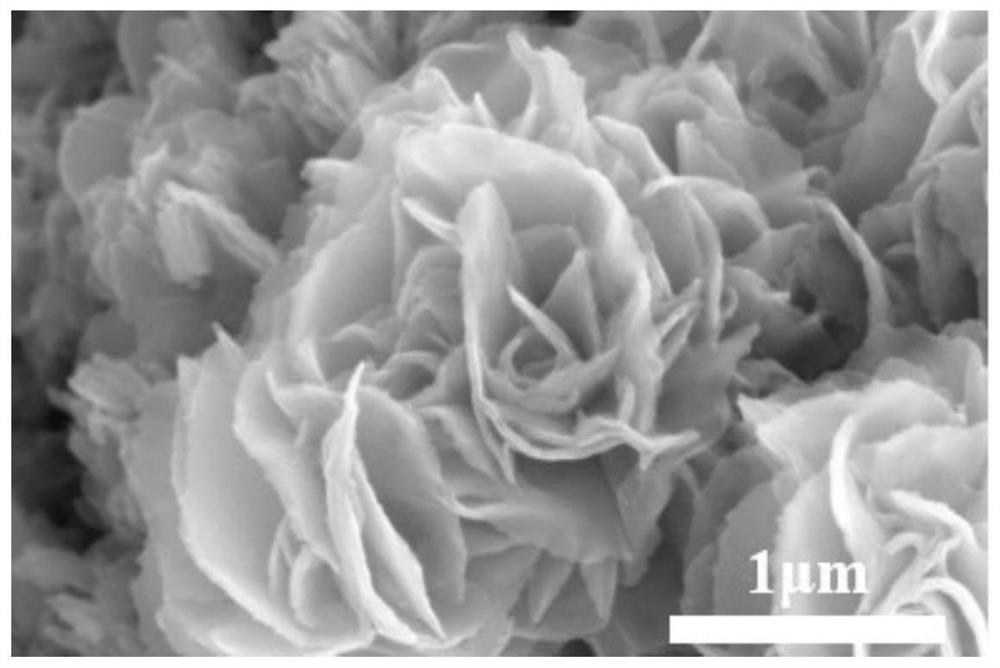

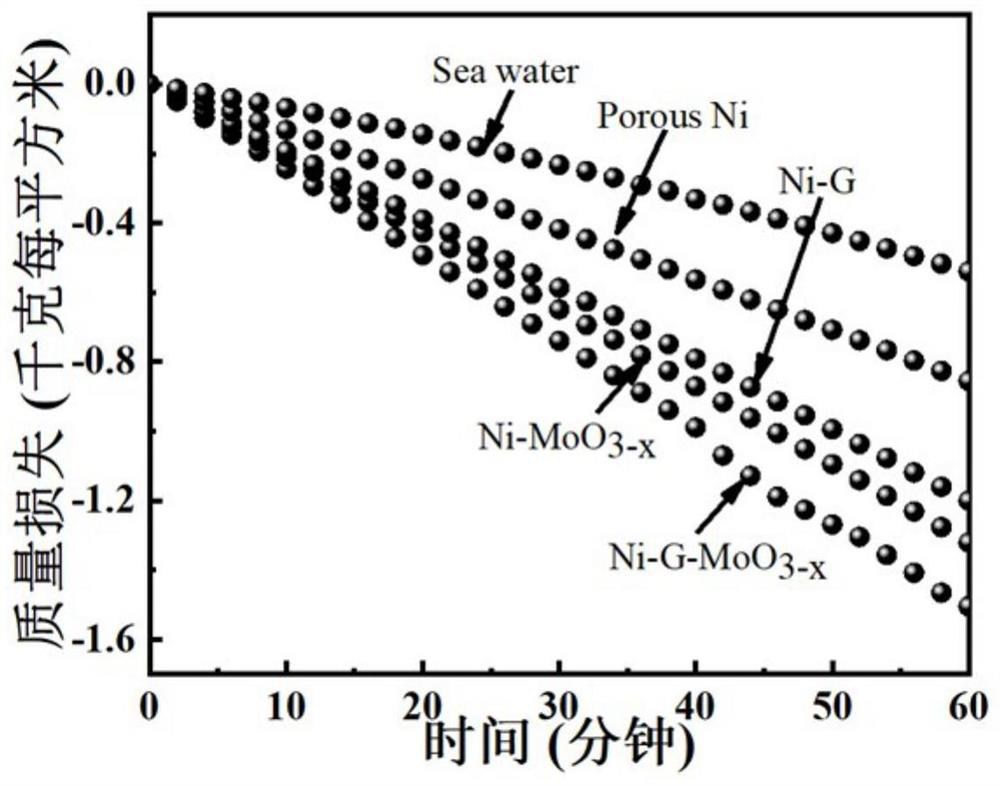

A three-dimensional integrated light-to-heat conversion material and its preparation method

ActiveCN113173616BEnhanced light absorptionFast preparationGeneral water supply conservationSeawater treatmentSuperhydrophilicityOcean environment

The invention discloses a three-dimensional integrated light-to-heat conversion material and a preparation method thereof. It prepares a foamed nickel graphene material by CVD on a pretreated foamed nickel substrate, and then prepares Ni-G-MoO3 by hydrothermal ‑x, the gas required for CVD is argon, high-purity hydrogen and high-purity methane; the performance parameters of the material are: thickness 0.5mm, evaporation rate under one light intensity is 1.50kg / m2h, efficiency is 95.8%, cycle stability More than 36h, hydrophilicity and hydrophobicity are superhydrophilicity. The invention combines graphene, molybdenum oxide and porous nickel foam through CVD and oxidation processes, which ensures that the material has a strong interfacial bonding force, and has super-hydrophilicity after one-step hydrothermal treatment, which can ensure the porous water absorption capacity of the material , At the same time, after the graphene covers the nickel foam surface, it can protect the application of the overall material in the marine environment and increase the service life of the material.

Owner:OCEAN UNIV OF CHINA

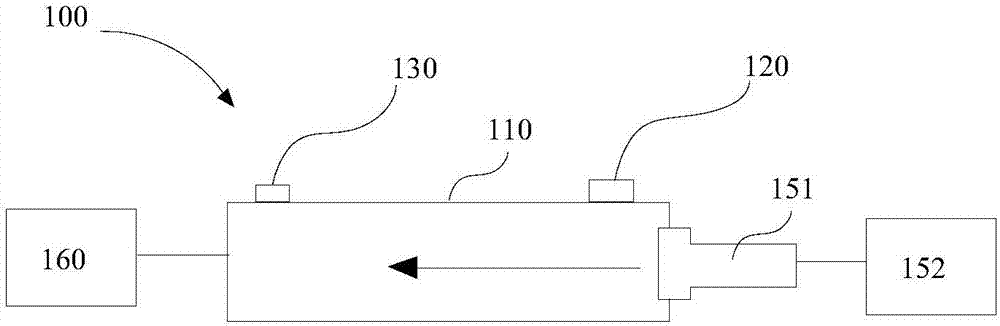

Evaporation device and evaporation equipment

ActiveCN111020491AStable pressureAvoid cloggingSolid-state devicesVacuum evaporation coatingEngineeringMechanical engineering

The invention provides an evaporation device and evaporation equipment. The evaporation device comprises an evaporation container and an anti-blocking cap which are connected or separated from each other; the anti-blocking cap comprises a first outlet, a first side wall, a first blade, a first opening, a second blade, a second opening and heating wires; the first side wall surrounds the first outlet; the first blade and the second blade are positioned in the first outlet and are fixed on the first side wall; the first blade surrounds the first opening; the second blade surrounds the second opening; the second opening is smaller than the first opening; the heating wires are arranged in the first side wall, the first blade and the second blade. The anti-blocking cap avoids instant large fluctuation of evaporation gas caused by melting, boiling or collapsing of evaporation raw materials in an evaporation container, and the emitting speed of the evaporation gas on the anti-blocking cap isstable. Therefore, the evaporation device realizes a stable evaporation rate, and further realizes an excellent evaporation effect; and in addition, the anti-blocking cap prevents the evaporation gasfrom being condensed on the second outlet of the evaporation container to cause blocking.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Evaporation device and evaporation method

ActiveCN107779822BAvoid depositionMonitor thicknessVacuum evaporation coatingSputtering coatingEvaporation (deposition)Condensed matter physics

The invention provides an evaporation device and an evaporation method. The vapor deposition device of the present invention is provided with a crystal vibrating plate shielding plate between the evaporation source and the crystal vibrating plate, and the crystal vibrating plate shielding plate can be switched between the two positions of shielding the crystal vibrating plate and not shielding the crystal vibrating plate; When the position of the crystal oscillator is not blocked, the evaporation material is deposited on the crystal oscillator plate, thereby avoiding the evaporation material from being deposited on the crystal oscillator plate; when the crystal oscillator plate shielding plate is in a position that does not block the crystal oscillator plate, the evaporation material can be deposited on the crystal oscillator plate; the present invention When the evaporation device is applied to the evaporation process, in the initial stage of evaporation, that is, the evaporation stage of the surface impurities of the material to be evaporated, the crystal oscillator shielding plate is in the position of blocking the crystal oscillator to prevent impurities from depositing on the surface of the crystal oscillator; After the impurities on the surface of the evaporation material are evaporated, the shielding plate of the crystal oscillator is in a position not to block the crystal oscillator, the evaporation material is deposited on the surface of the crystal oscillator, and the deposition rate monitoring device obtains a stable evaporation rate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

A kind of parylene F-type vapor deposition method

ActiveCN113025960BImprove performanceGuaranteed performanceVacuum evaporation coatingSputtering coatingEvaporation (deposition)Parylene

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

Evaporation chamber lining device, evaporation system, and evaporation device

ActiveCN110284108BGuaranteed evaporation rate stabilityReduce loss costsVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

The invention relates to the technical field of semiconductor technology, in particular to an evaporation chamber lining device, an evaporation system, and an evaporation device. The evaporation chamber lining device provided by the present invention includes a chamber assembly, and the chamber assembly includes, a first shell having a first open end and a second open end oppositely arranged, and the first open end The evaporation device is externally connected, and a steam channel suitable for steam circulation is formed in the first housing; a second housing is communicated with the second open end, and a channel for retaining steam from the steam channel is formed in the second housing. Material storage area. The evaporation chamber lining device provided by the present invention can ensure that the evaporation device can raise the temperature of the organic material in advance, without worrying that the evaporated material will enter the evaporation area and cause interference to the substrate.

Owner:SUZHOU QUINGYUE OPTOELECTRONICS TECH CO LTD

Evaporation source device

InactiveCN105200372AImprove evaporation qualityReduce evaporation costVacuum evaporation coatingSputtering coatingEngineeringConductor Coil

The invention discloses an evaporation source device which comprises an evaporation boat and hollow pipelines, wherein the hollow pipelines are tightly clung to the outer side of the evaporation boat in a uniform winding manner; circulating mediums are introduced into the hollow pipelines, and comprise a heating circulating medium and a cooling circulating medium. The evaporation source device adopts the manner that the circulating mediums are directly used for heating and cooling; after the heating circulating medium is quickly introduced, the evaporation time of an evaporation material can be reached within a quite short time period; after the cooling circulating medium is quickly introduced, the evaporation boat can be quickly cooled after the evaporation is completed, the evaporation material is saved, and the evaporation cost is reduced.

Owner:SICHUAN CCO DISPLAY TECH

Sustained-release microcapsules for attractant of Beetle beetle, preparation method and application thereof

ActiveCN113841693BInhibit volatilization rateLong durationBiocidePest attractantsPolyvinyl alcoholCapsule

The present invention discloses a slow-release microcapsule for attracting beetles, and a preparation method and application thereof. The capsule comprises a wall material and a core material, wherein the wall material is made of 2-methyl-2-methyl acrylate, 2-methyl-2-methyl acrylate, 2-methyl-2-methyl acrylate, 2 ‑Methyl‑2‑acrylic acid and dibenzoyl peroxide; the core material is prepared from the beetle pheromone Conophthorin, n-hexane and paraffin, and the wall material and core material are emulsified with polyvinyl alcohol to obtain a sustained-release microbe. capsule. The capsules are installed in the trap to lure and kill the beetles, preventing or reducing their reproduction, so as to protect the host plants.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

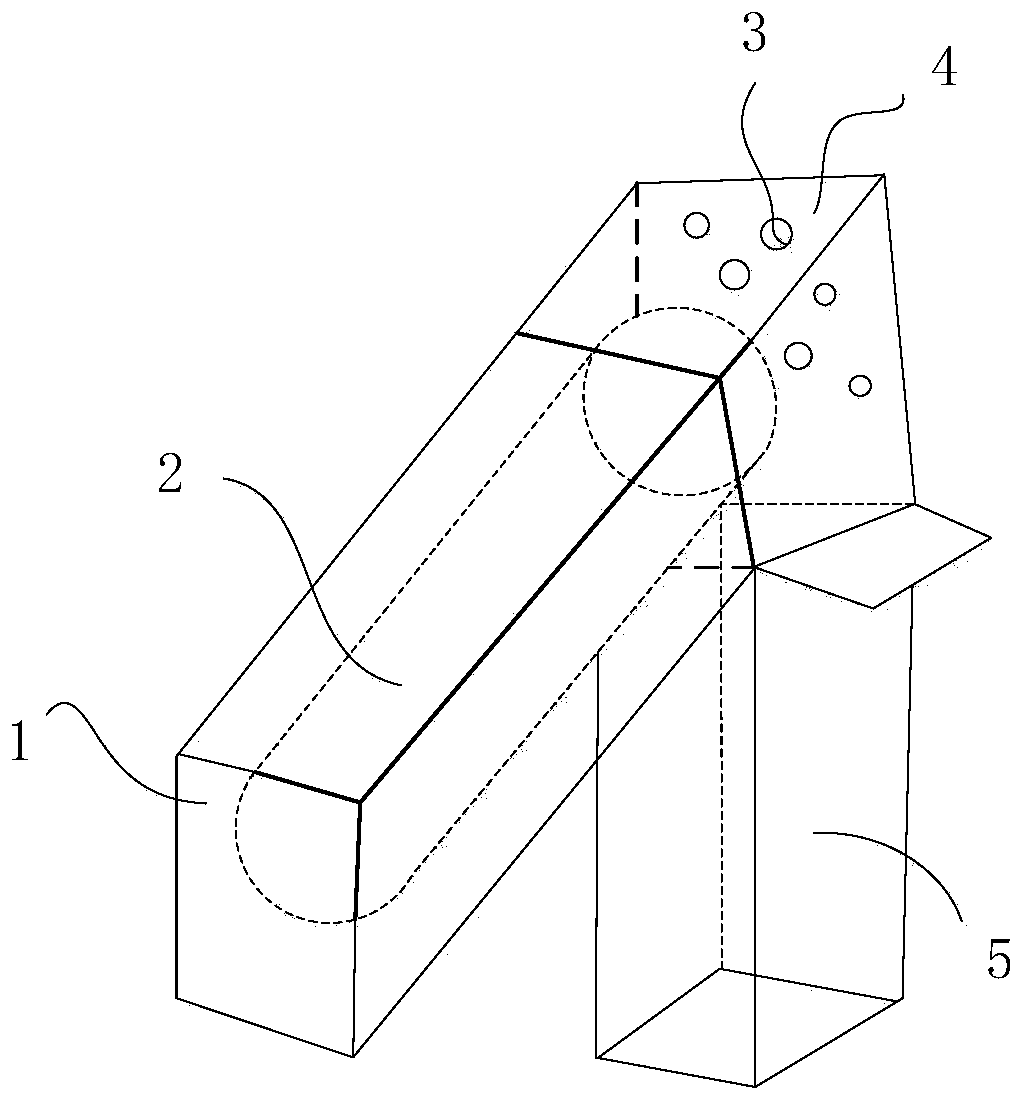

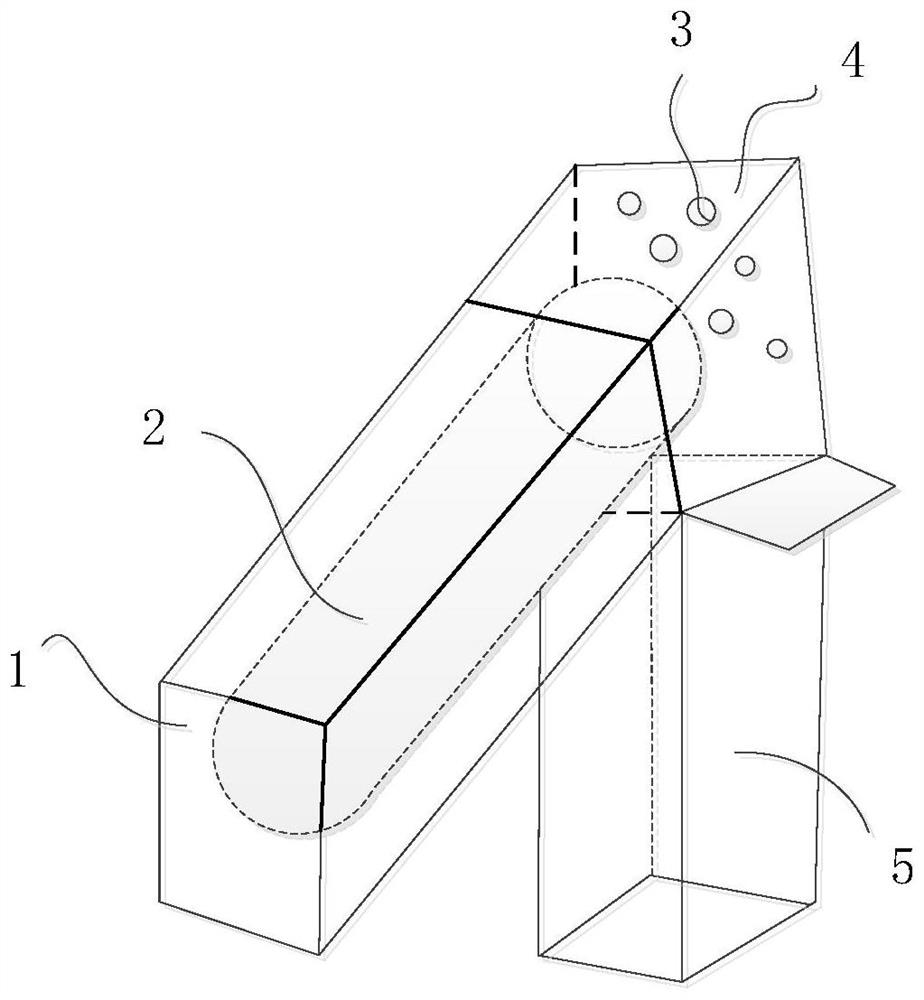

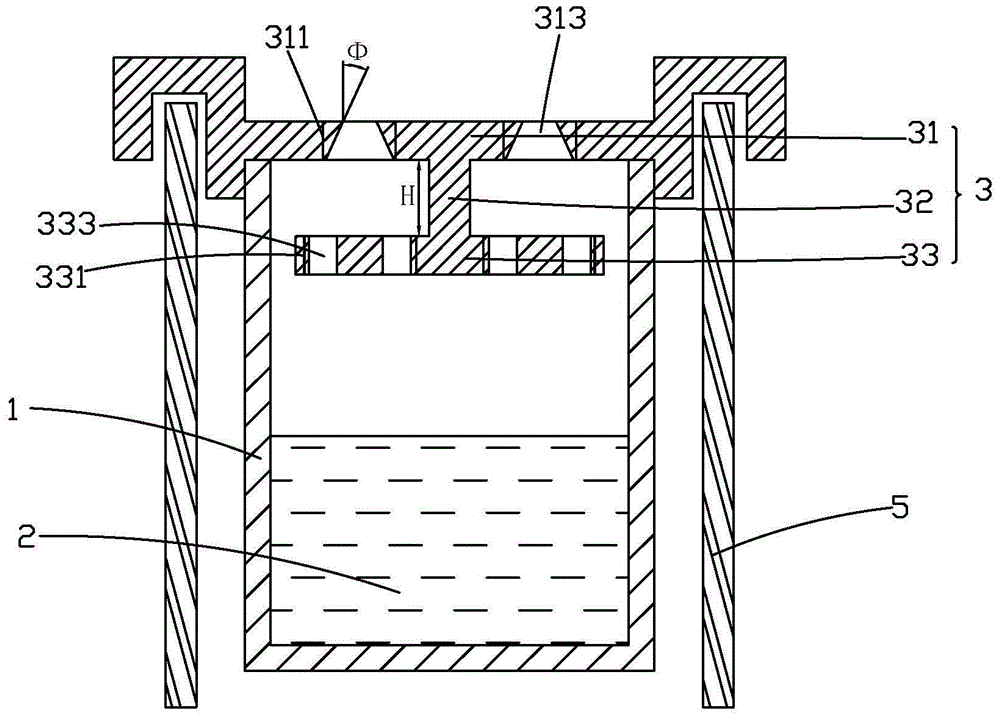

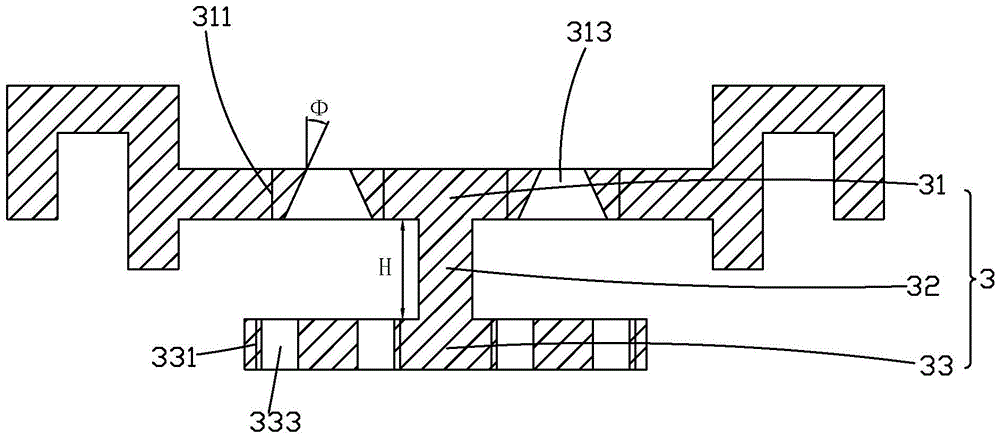

Crucible to prevent splashing and plugging of evaporation materials

ActiveCN104593729BImprove utilizationImprove stabilityVacuum evaporation coatingSolid-state devicesCrucibleEngineering

The invention provides a crucible for preventing evaporation materials from splashing and hole plugging, comprising a crucible body (1) for accommodating evaporation materials (2), and a cover body (3) covering the opening end of the crucible body (1) ); the lid (3) includes a loam cake (31), a lower lid (33) and a connecting portion (32) connecting the loam cake (31) and the lower lid (33); the loam cake (31) It is spaced apart from the lower cover (33) along the axial direction of the crucible body (1); several upper air outlets (313) are arranged in the upper opening area (311) of the upper cover (31), and the lower cover (33) Several lower air outlets (333) are arranged in the lower opening area (331), and the several upper air outlets (313) do not overlap with the several lower air outlets (333). The invention can improve the heat balance inside the large-diameter crucible and the balance between temperature and evaporation rate, solve the problems of unstable evaporation rate, easy blockage of air holes and material splashing during pre-melting, improve the stability of the evaporation process, and improve the evaporation rate. Plating equipment utilization rate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

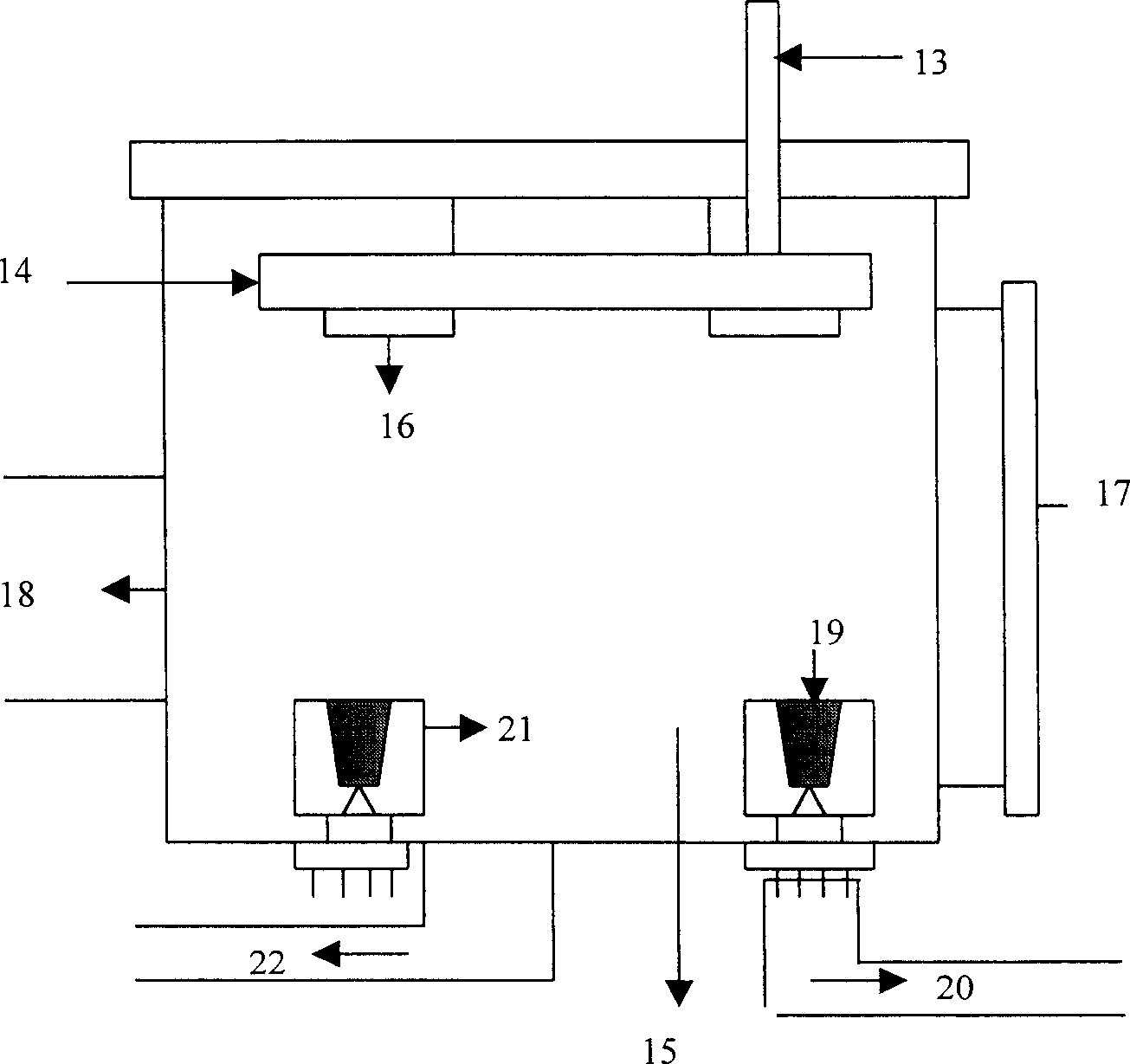

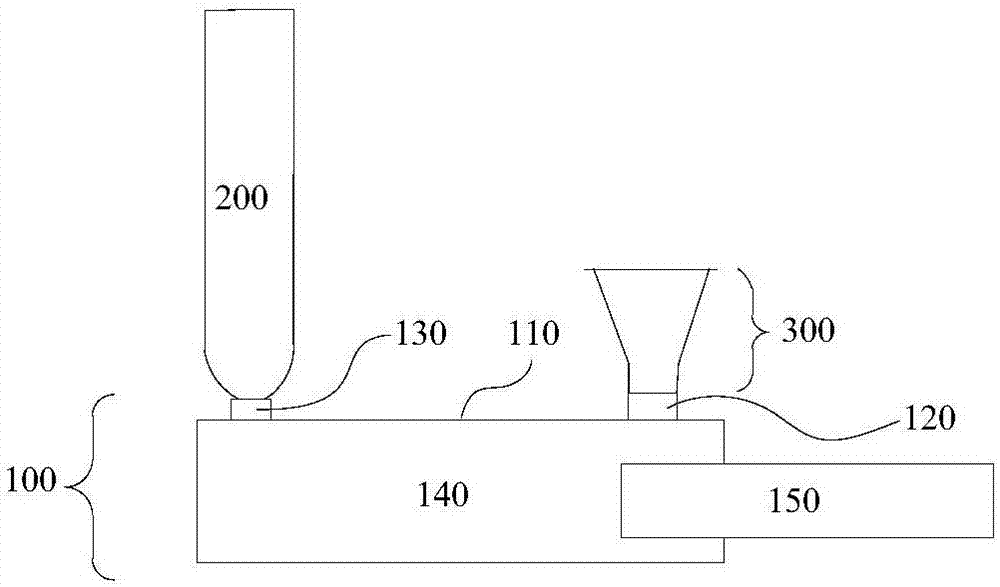

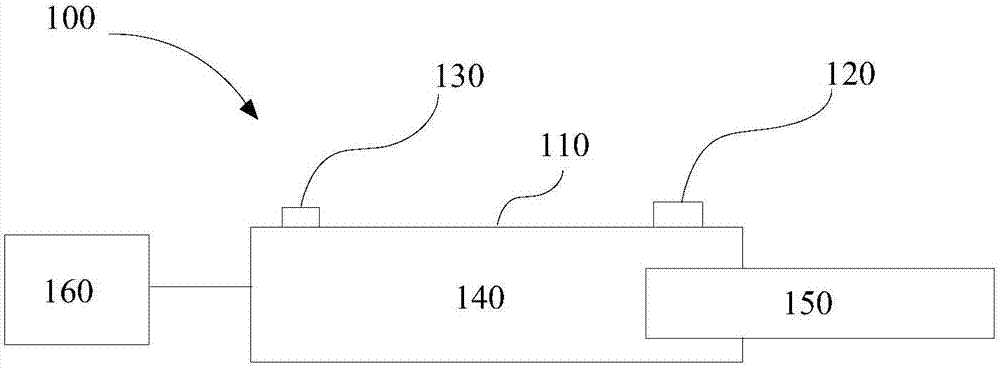

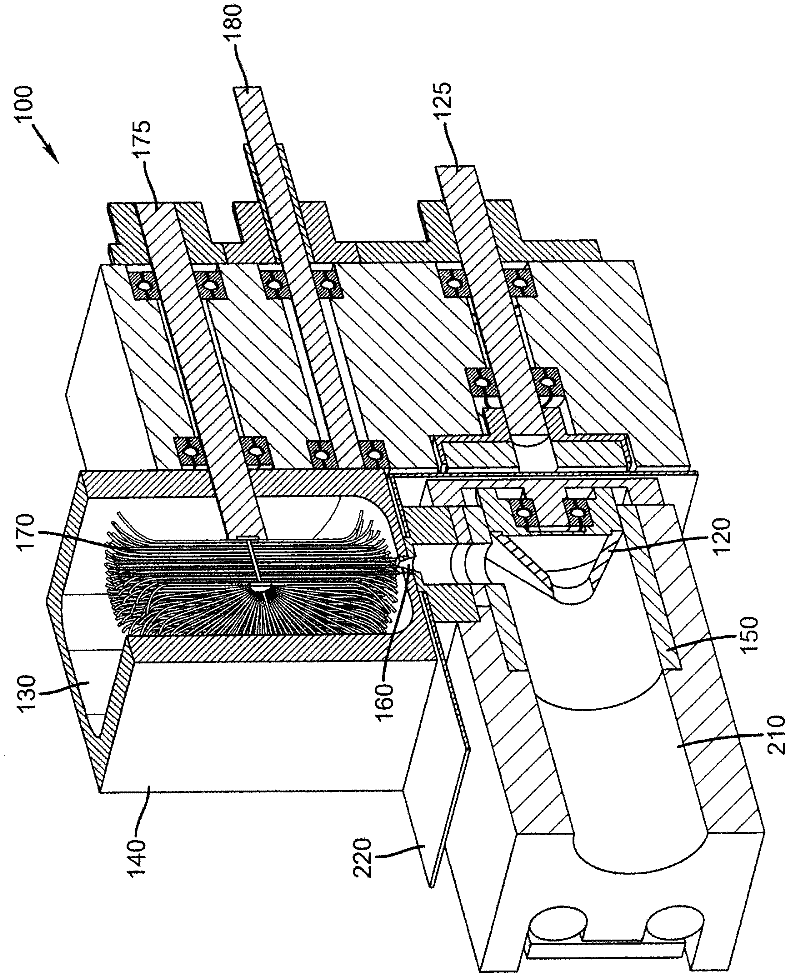

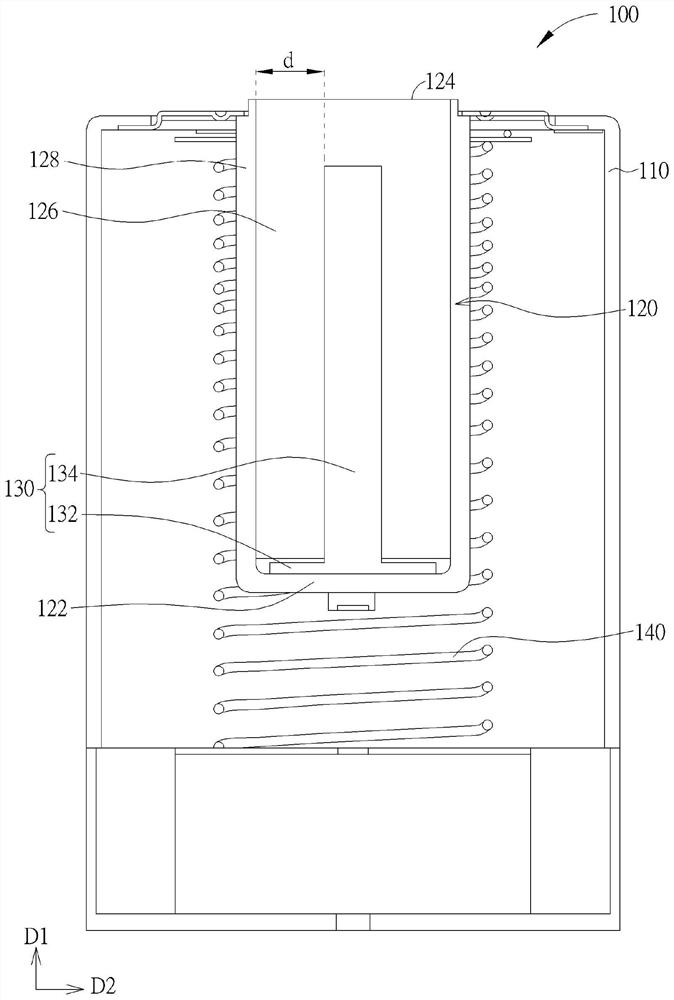

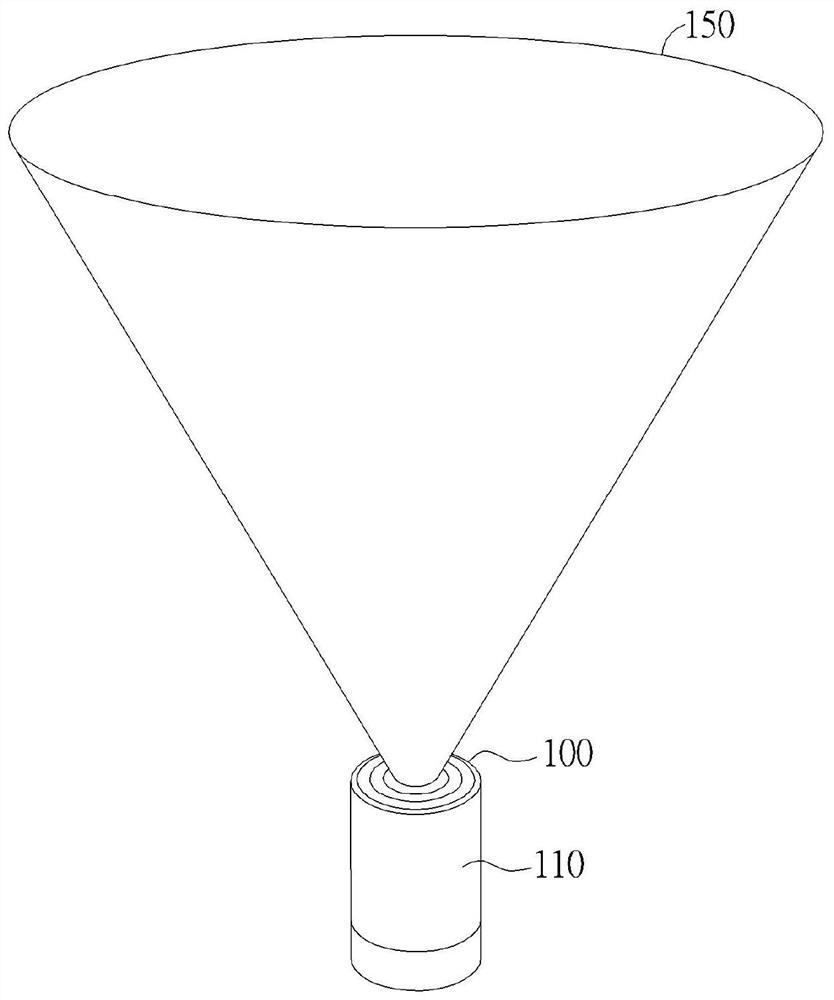

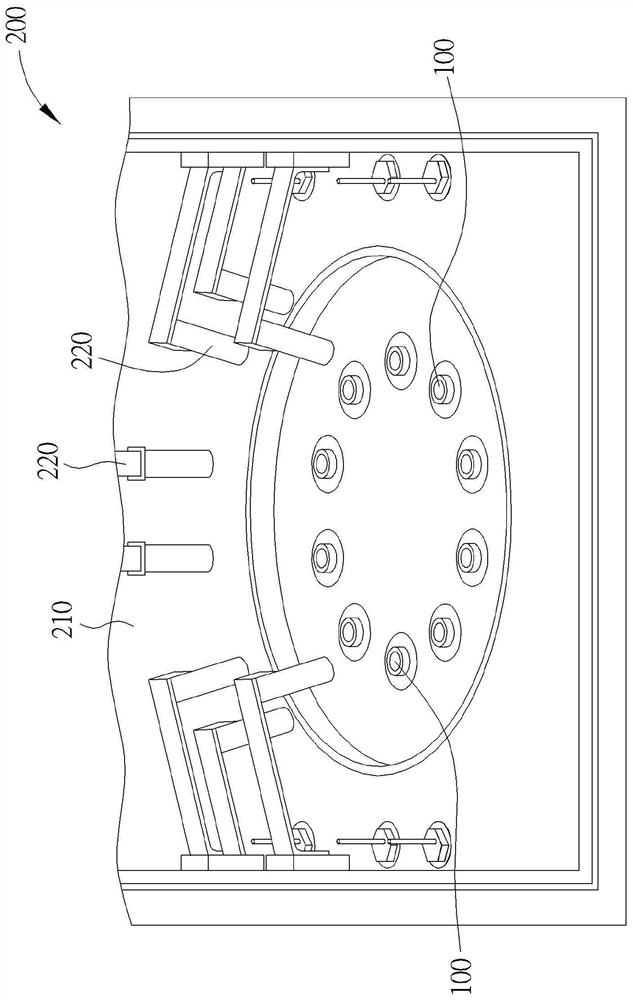

Simplified powder feeding and vaporization apparatus

InactiveCN102317497AUniform meteringEvaporation rate is stableVacuum evaporation coatingSputtering coatingVaporizationEngineering

An apparatus (100) for vaporizing a particulate material, including: a metering apparatus including: a reservoir (130) for receiving particulate material: the reservoir having an opening (160) for discharging the particulate material into a vaporizing chamber (210); a rotatable wire wheel brush (170) disposed in the reservoir; wherein the dimensions of the reservoir and the wire wheel brush are selected so that the wire wheel brush cooperates with the interior walls of the reservoir to fluidize the particulate material and wherein a metered portion of the particulate material is entrained in the tines of the wire wheel brush and subsequently forcefully released into the reservoir opening; and a flash evaporator (120) that receives and vaporizes the metered material.

Owner:GLOBAL OLED TECH

Heating device and evaporation device using same

PendingCN113817989AEvenly heatedUniform heating and evaporationVacuum evaporation coatingSputtering coatingThermodynamicsCrucible

Owner:SYSKEY TECH CO LTD

System for supplying stable liquid source for ammonia volatilization

InactiveCN102153108BEvaporation rate is stableEasy to operateAmmonia preparation/separationWater storage tankEngineering

The invention discloses a circulating system for supplying a stable liquid source for ammonia volatilization. A prepared ammonia solution is placed in a water storage tank; one end of a regulating valve is connected with a circulating pump arranged in the water storage tank through a first hose, and the other end of the regulating valve is connected into a test tank through a second hose; and oneend of a third hose is connected into the water storage tank, the other end of the third hose is connected with the end of a right-angle copper pipe, which is parallel to the liquid level, and the end of the right-angle copper pipe, which is perpendicular to the liquid level, keeps consistent with the level of the ammonia solution. The volatilization speed of ammonia on the surface of the solution can keep stable; by using the circulating system, the characteristics such as pH value and total ammonia nitrogen concentration of the solution can keep roughly same within long time; the pH value of the solution can be regulated as required, and the operation is convenient. The circulating system provided by the invention can be used for preparing ammonia in scientific researches.

Owner:ZHEJIANG UNIV

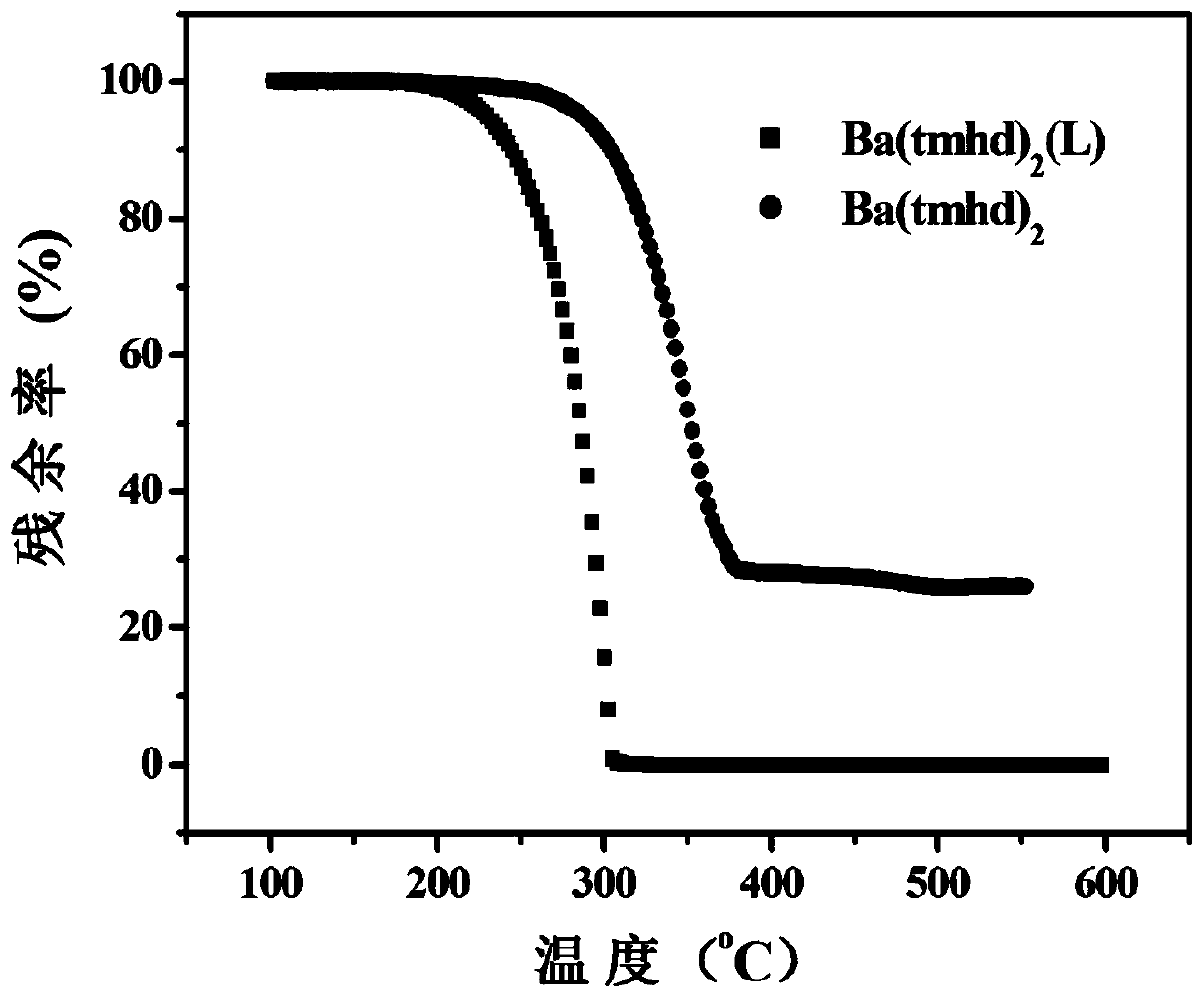

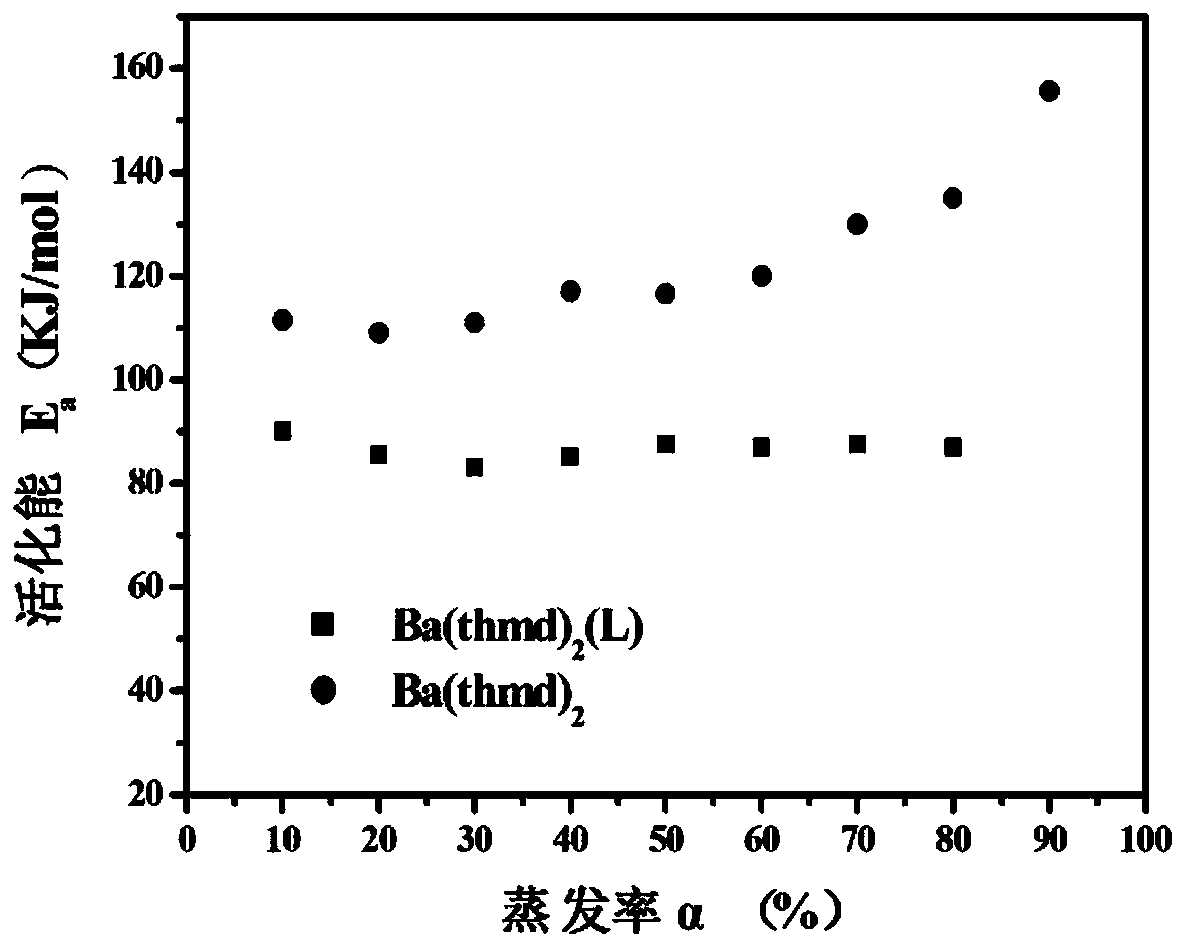

A kind of preparation method and application of highly volatile composite ligand barium precursor salt

InactiveCN108707159BEasy to manufactureImprove stabilitySuperconductors/hyperconductorsSuperconductor devicesBarium saltMethyl group

Owner:BEIJING JIAOTONG UNIV +1

Etching apparatus and technology thereof

InactiveCN100524651CAvoid air embolismReduce evaporation rateSemiconductor/solid-state device manufacturingTemperature controlRoom temperature

Owner:CHUNGHWA PICTURE TUBES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com