Crucible to prevent splashing and plugging of evaporation materials

A technology of evaporation materials and plug holes, which is applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of easy blockage of air outlet, material splashing, unstable evaporation rate, etc. Achieve the effects of increasing utilization rate, improving stability, and solving unstable evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

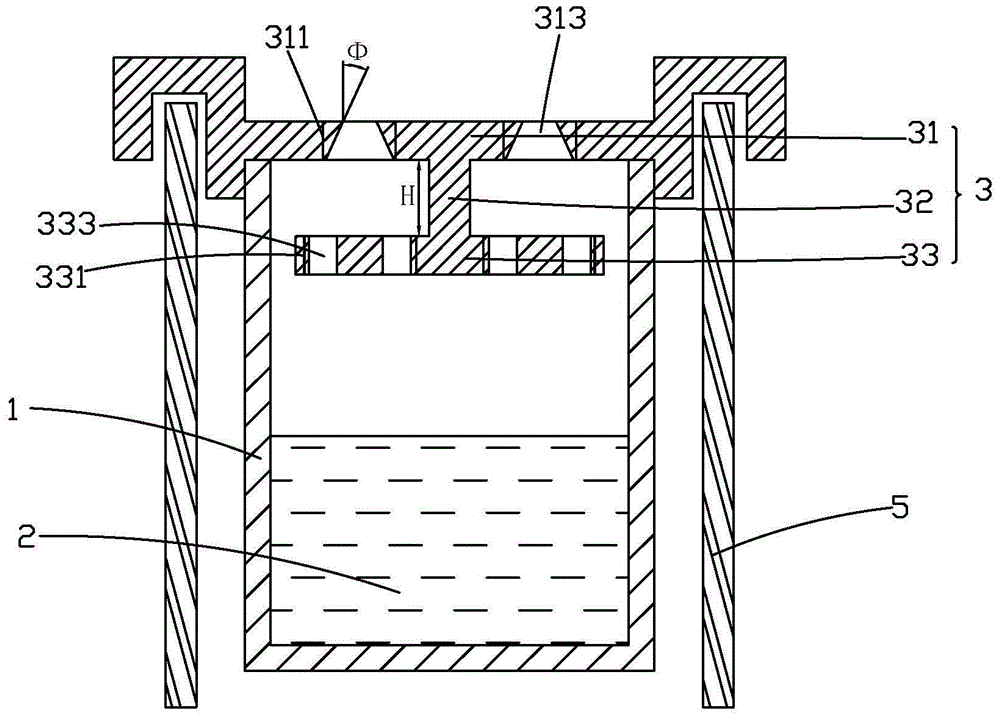

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

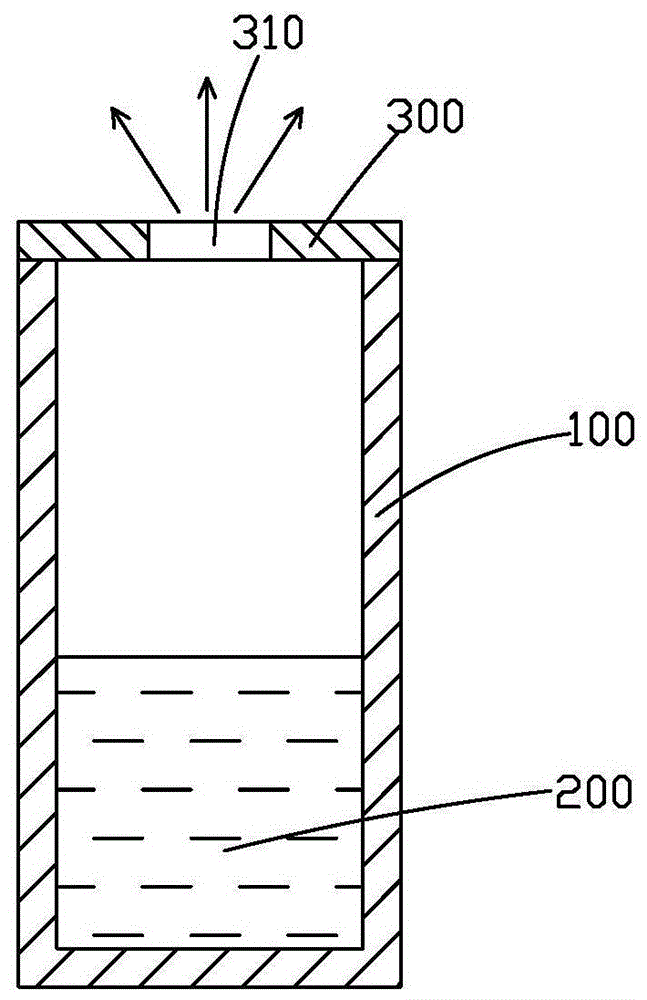

[0037] see figure 2 , image 3 , The present invention provides a crucible for preventing evaporation material splashing and hole plugging, comprising a crucible body 1 for containing evaporation material 2 and a cover body 3 covering the opening end of the crucible body 1 .

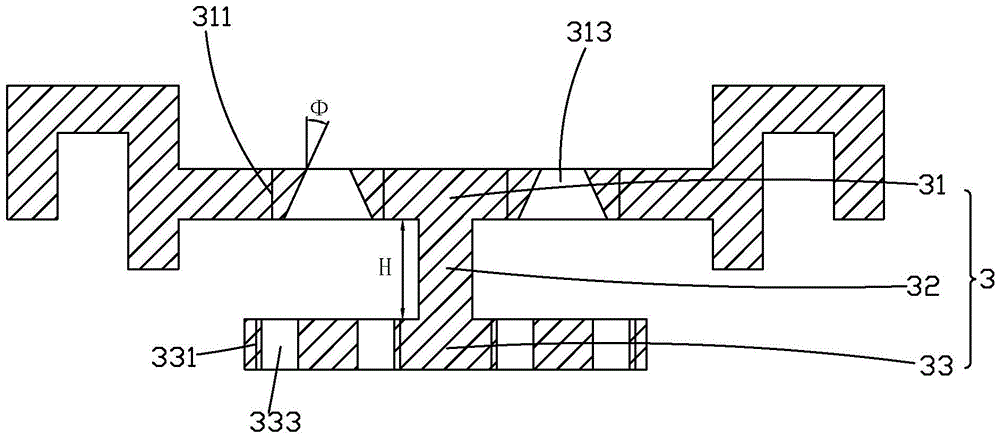

[0038] The cover body 3 includes an upper cover 31 , a lower cover 33 and a connecting portion 32 connecting the upper cover 31 and the lower cover 33 ; the upper cover 31 and the lower cover 33 are spaced apart along the axial direction of the crucible body 1 .

[0039] The inner diameter of the upper cover 31 is equal to the outer diameter of the crucible body 1 and is located at the opening end of the crucible body 1; the outer diameter of the lower cover 33 is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com