Sustained-release microcapsules for attractant of Beetle beetle, preparation method and application thereof

A slow-release microcapsule and attractant technology, which is applied in the direction of microcapsule preparation, microsphere preparation, and attractant pests, can solve the problems of easy volatilization of pheromones and unsatisfactory slow-release effects of pheromones, and achieve environmental pollution. The effect of small size, long-lasting effect and less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

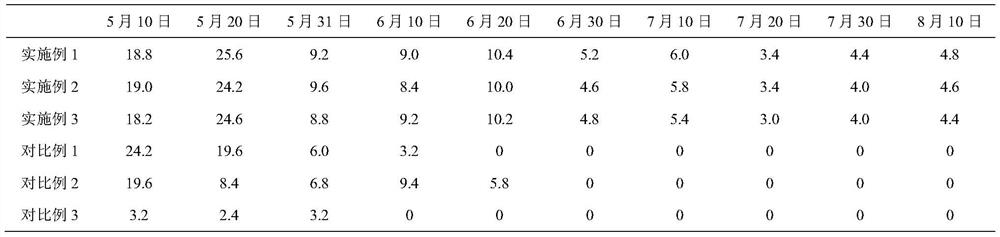

Examples

Embodiment 1

[0026] A kind of slow-release microcapsules of the lupus beetle attractant, when specifically prepared:

[0027] (1) 0.5 g of dibenzoyl peroxide was added to the mixed solution containing 40 g of 2-methyl-2-methyl acrylate and 10 g of 2-methyl-2-acrylic acid, and carried out in a water bath at 70° C. Heating, after heating for 30 minutes, stirring was performed at a rate of about 300 rpm to obtain a prepolymerized liquid (wall material).

[0028] (2) Take 0.05 g of the beetle pheromone Conophthorin with a purity of more than 90%, dissolve it in 5 g of n-hexane solution, and finally add 5 g of paraffin solution to obtain a microcapsule core material mixture.

[0029] (3) Take 10g of the above-mentioned prepolymerization liquid and the microcapsule core material mixture, mix with 20g of a polyvinyl alcohol (PVA) aqueous solution with a mass concentration of 0.2% to carry out shear emulsification, and the emulsification process is carried out in a high shear emulsifier, The reac...

Embodiment 2

[0031] A kind of slow-release microcapsules of the lupus beetle attractant, when specifically prepared:

[0032] (1) Add 0.5g of dibenzoyl peroxide to the mixed solution containing 37.5g of 2-methyl-2-methyl acrylate and 9g of 2-methyl-2-acrylic acid, and place in a water bath at 70°C. Heating was carried out in the medium, and after heating for 30 minutes, stirring was performed at a rate of about 280 rpm to obtain a prepolymerized liquid (wall material).

[0033] (2) Take 0.05 g of the beetle pheromone Conophthorin with a purity of more than 90%, dissolve it in 4.9 g of n-hexane solution, and finally add 4.9 g of paraffin solution to obtain a microcapsule core material mixture.

[0034] (3) Take 9g of each of the above-mentioned prepolymerization liquid and the microcapsule core material mixture, mix with 18g of a polyvinyl alcohol (PVA) aqueous solution with a mass concentration of 0.2%, and perform shear emulsification, and the emulsification process is carried out in a hi...

Embodiment 3

[0036] A kind of slow-release microcapsules of the lupus beetle attractant, when specifically prepared:

[0037] (1) Add 0.5 g of dibenzoyl peroxide to a mixed solution containing 42.5 g of methyl 2-methyl-2-acrylate and 12.5 g of 2-methyl-2-acrylic acid, and place in a water bath at 80° C. The pot was heated, and after heating for 30 minutes, stirring was carried out at a rate of about 330 rpm to obtain a prepolymerized liquid (wall material).

[0038] (2) Take 0.05 g of beetle pheromone Conophthorin with a purity of more than 90%, dissolve it in 5.25 g of n-hexane solution, and finally add 5.15 g of paraffin solution to obtain a microcapsule core material mixture.

[0039] (3) Take 10g of each of the above-mentioned prepolymerization liquid and capsule core material mixture, mix with 20g of polyvinyl alcohol (PVA) aqueous solution with a mass concentration of 0.2%, and perform shear emulsification, and the emulsification process is carried out in a high shear emulsifier. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com