Attractant sustained-release microcapsule for Xylosandrus crassiusculus as well as preparation method and application thereof

A technology for slow-release microcapsules and attractants, which is applied in the directions of microcapsule preparations, microsphere preparation, and harmful attractants, etc., can solve the problems of unsatisfactory slow-release effect of pheromones and volatile pheromones, and achieve environmental pollution. Small, easy to use, stable volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

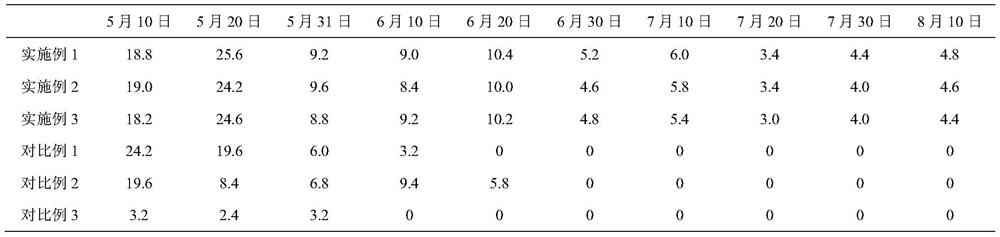

Examples

Embodiment 1

[0026] A kind of slow-release microcapsules of dark-winged bark beetle attractant, during specific preparation:

[0027] (1) Add 0.5g of dibenzoyl peroxide to the mixture of 40g of 2-methyl-2-acrylate methyl ester and 10g of 2-methyl-2-acrylic acid mixture, and carry out in a 70°C water bath Heating, after heating for 30 minutes, keep stirring at a speed of about 300 rpm to obtain a pre-polymerization solution (wall material).

[0028] (2) Take 0.05 g of bark beetle pheromone Conophthorin with a purity of more than 90%, dissolve it in 5 g of n-hexane solution, and finally add 5 g of paraffin wax solution to obtain a microcapsule core material mixture.

[0029] (3) 10g of the above-mentioned pre-polymerization solution and the microcapsule core material mixture are respectively taken, and mixed with 0.2% polyvinyl alcohol (PVA) aqueous solution with 20g mass concentration to carry out shear emulsification, and the emulsification process is carried out in a high-shear emulsifier...

Embodiment 2

[0031] A kind of slow-release microcapsules of dark-winged bark beetle attractant, during specific preparation:

[0032] (1) Add 0.5g of dibenzoyl peroxide to a mixture of 37.5g of 2-methyl-2-methyl acrylate and 9g of 2-methyl-2-acrylic acid, and place in a 70°C water bath After heating for 30 minutes, keep stirring at a speed of about 280rpm to obtain a prepolymerized solution (wall material).

[0033] (2) Take 0.05 g of bark beetle pheromone Conophthorin with a purity of more than 90%, dissolve it in 4.9 g of n-hexane solution, and finally add 4.9 g of paraffin wax solution to obtain a microcapsule core material mixture.

[0034] (3) 9g of the above-mentioned pre-polymerization liquid and the microcapsule core material mixture are respectively taken, and mixed with 0.2% polyvinyl alcohol (PVA) aqueous solution with 18g mass concentration to carry out shear emulsification, and the emulsification process is performed in a high-shear emulsifier To carry out, the reaction tempe...

Embodiment 3

[0036] A kind of slow-release microcapsules of dark-winged bark beetle attractant, during specific preparation:

[0037] (1) Add 0.5g of dibenzoyl peroxide to a mixture of 42.5g of 2-methyl-2-acrylic acid methyl ester and 12.5g of 2-methyl-2-acrylic acid in a water bath at 80°C Heat in the pot, and after heating for 30 minutes, keep stirring at a speed of about 330 rpm to obtain a pre-polymerized solution (wall material).

[0038] (2) Take 0.05 g of bark beetle pheromone Conophthorin with a purity of more than 90%, dissolve it in 5.25 g of n-hexane solution, and finally add 5.15 g of paraffin wax solution to obtain a microcapsule core material mixture.

[0039] (3) 10g of the above-mentioned pre-polymerization liquid and capsule core material mixture are respectively taken, mixed with 20g mass concentration of 0.2% polyvinyl alcohol (PVA) aqueous solution to carry out shear emulsification, and the emulsification process is carried out in a high-shear emulsifier , the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com