A multifunctional anti-heat radiation coating and its spraying process on steel surface

A thermal radiation coating and multi-functional technology, applied in the direction of surface coating liquid devices, coatings, pre-treated surfaces, etc., can solve the problems of difficult precise control and realization, and achieve enhanced thermal radiation protection effect, Improve the binding force and improve the effect of heat radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

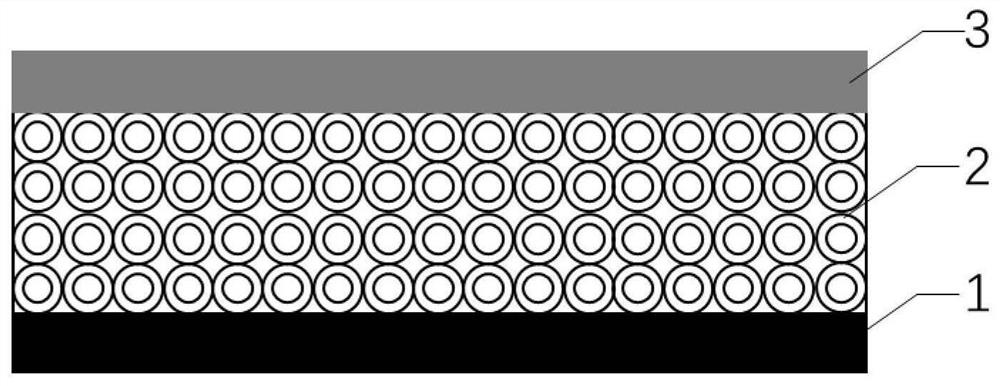

[0054] A multifunctional anti-heat radiation coating, from bottom to top, comprises a base coating of 0.3 mm, a thermal radiation protection coating of 2 μm and a wear-resistant coating of 0.3 mm;

[0055] The base coating includes the following components in parts by weight: 40 parts of polyether modified epoxy resin, 10 parts of titanium dioxide, 10 parts of hollow silica microspheres, 35 parts of water, 1.5 parts of defoamer, leveling 1.5 parts of agent and 2 parts of preservative;

[0056] The anti-heat radiation coating includes 4 layers of hollow silica microspheres with a particle size of 0.5 μm;

[0057] The wear-resistant coating includes the following components in parts by weight: 15 parts of zircon powder, 12 parts of diatomaceous earth, 36 parts of polyvinyl alcohol, 6 parts of sodium bentonite, 26 parts of water, 1.5 parts of defoamer, leveling 1.5 parts of the agent and 2 parts of the preservative.

[0058] The spraying process of the anti-heat radiation coati...

Embodiment 2

[0066] The difference between Example 2 and Example 1 is that step S4 is specifically: when the evaporation rate of the water in the base coating described in step S3 reaches 45-50%, the hollow silica microsphere particles The surface is coated with polyvinyl alcohol, and then sprayed onto the surface of the base coating to a thickness of about 2 μm. At this time, the number of layers of hollow silica microsphere particles is about 4 layers. Others are basically the same as those in Embodiment 1, and are not repeated here.

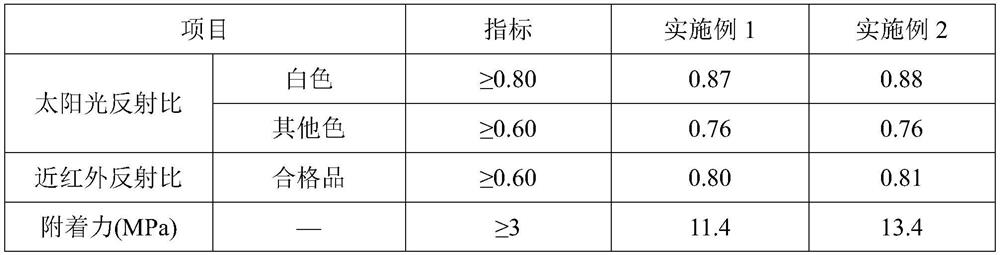

[0067] The test results are shown in Table 1. It can be seen that the exothermic radiation properties and adhesion of the steels sprayed with the multifunctional anti-heat radiation coating obtained in Examples 1 and 2 are significantly higher than the standard indicators, indicating that the present invention is more effective. The functional heat radiation protection coating has good heat radiation protection performance and good adhesion to steel. Afte...

Embodiment 3~9 and comparative example 1~4

[0071] Compared with Example 2, the multifunctional anti-heat radiation coatings provided in Examples 3-9 and Comparative Examples 1-4 are different in that the coating thickness and preparation conditions are shown in Table 2, and the others are basically the same as those in Example 1. are the same and will not be repeated here.

[0072] Table 2 Preparation conditions of Examples 3-9 and Comparative Examples 1-4

[0073]

[0074] Table 3 Test results of Examples 3 to 9 and Comparative Examples 1 to 4

[0075]

[0076]

[0077] It can be seen from Table 3 that the increase in the thickness of the anti-radiation coating helps to improve the anti-radiation performance of the steel, while the adhesion does not change much. With the increase of the particle size of the hollow silica microspheres, the thermal radiation resistance first increased and then decreased. This may be because the gap between the hollow silica microspheres is reduced if the particle size is too ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com