Environment-friendly cultivation bag material for container grafting camellia oleifera seedlings

A container-grafted seedling and cultivation bag technology, which is applied in application, culture medium, planting substrate, etc., can solve the problems of easy water loss and dryness of seedlings, insufficient supply of trace elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

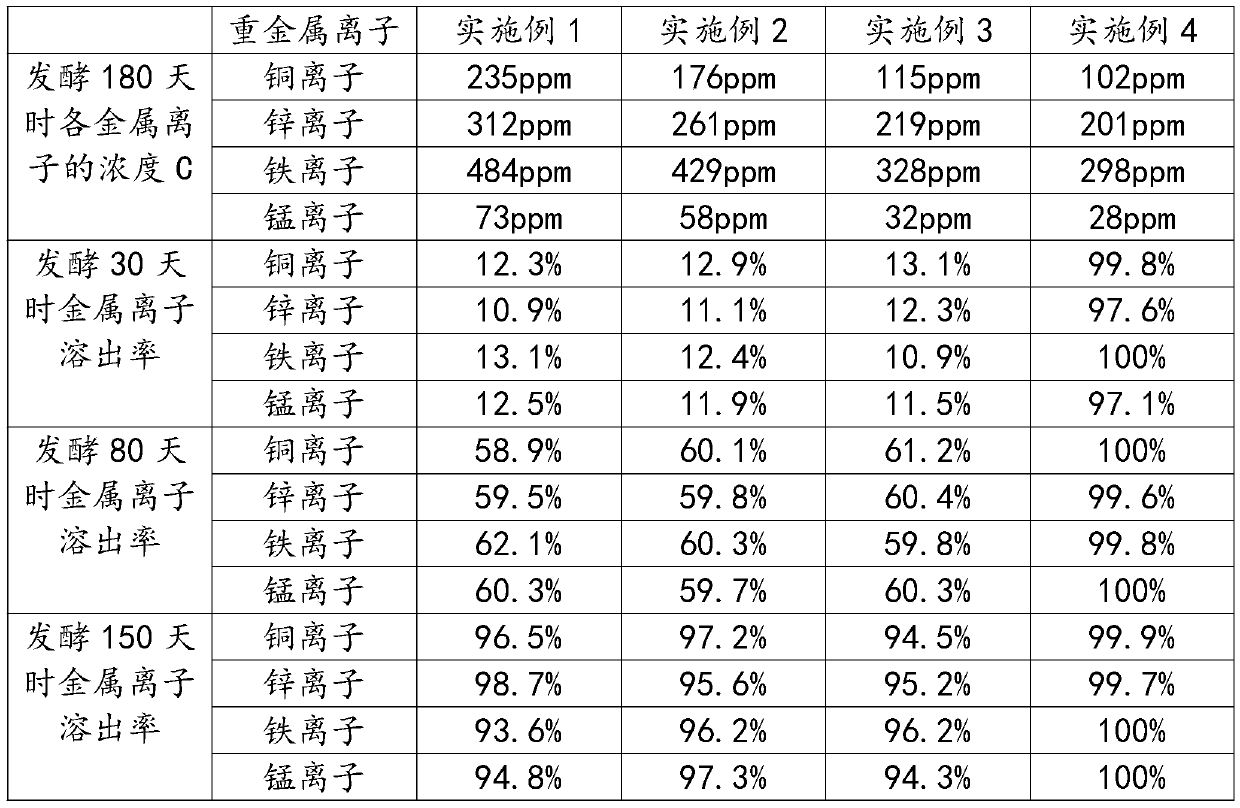

Examples

Embodiment 1

[0023] The specific preparation process of modified diatomite is as follows:

[0024] Step 1: Add 10 g of diatomite to 80 mL of 7% hydrochloric acid solution and stir for 1-1.5 hours, then filter and wash until neutral, then dry to obtain pretreated diatomite;

[0025]Step 2: the copper nitrate solution with a mass concentration of 2.8-3.1%, the zinc nitrate solution with a mass concentration of 3.6-3.9%, the ferric nitrate solution with a mass concentration of 5.2-5.8%, and the manganese nitrate with a mass concentration of 0.8-0.9% Mix according to the mass ratio of 1:1:1:1 to form a metal mixture;

[0026] Step 3: Weigh 90mL of metal mixed solution into the reaction vessel, add 10g of pretreated diatomite to it, stir and impregnate for 30-40min, then add 90mL of sodium hydroxide solution with a mass concentration of 5% to the reaction vessel dropwise , control the rate of addition to 8-9mL / min, stir while adding dropwise, add 8-9mL dropwise until a white precipitate precip...

Embodiment 2

[0030] The specific preparation process of modified diatomite is as follows:

[0031] Step 1: Copper nitrate solution with a mass concentration of 2.8-3.1%, zinc nitrate solution with a mass concentration of 3.6-3.9%, ferric nitrate solution with a mass concentration of 5.2-5.8% and manganese nitrate with a mass concentration of 0.8-0.9% Mix according to the mass ratio of 1:1:1:1 to form a metal mixture;

[0032] Step 2: Take 90mL metal mixed solution and add it to the reaction vessel, add 10g of diatomaceous earth therein, stir and impregnate for 30-40min, then add 90mL of sodium hydroxide solution with a mass concentration of 5% dropwise to the reaction vessel, control The dropping rate is 8-9mL / min, stir while adding dropwise, add 8-9mL dropwise until white precipitates are precipitated to stop the dropwise addition, then stir and react at constant temperature for 2-3h, then filter, wash and dry to obtain the loaded diatomite;

[0033] Step 3: Weigh 100mL of metal mixed s...

Embodiment 3

[0036] The specific preparation process of modified diatomite is as follows:

[0037] Step 1: Add 10 g of diatomite to 80 mL of 7% hydrochloric acid solution and stir for 1-1.5 hours, then filter and wash until neutral, then dry to obtain pretreated diatomite;

[0038] Step 2: the copper nitrate solution with a mass concentration of 2.8-3.1%, the zinc nitrate solution with a mass concentration of 3.6-3.9%, the ferric nitrate solution with a mass concentration of 5.2-5.8%, and the manganese nitrate with a mass concentration of 0.8-0.9% Mix according to the mass ratio of 1:1:1:1 to form a metal mixture;

[0039] Step 3: Weigh 100mL of metal mixed solution and heat it to 85-90°C, then add 13g of polyvinyl alcohol to it and stir to dissolve, then add 21g of starch to it, stir while adding, stir and disperse evenly after the addition is complete, and then use ultrasonic Disperse at low temperature for 10-15min to obtain the coating agent;

[0040] Step 4: Add the pretreated diato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com