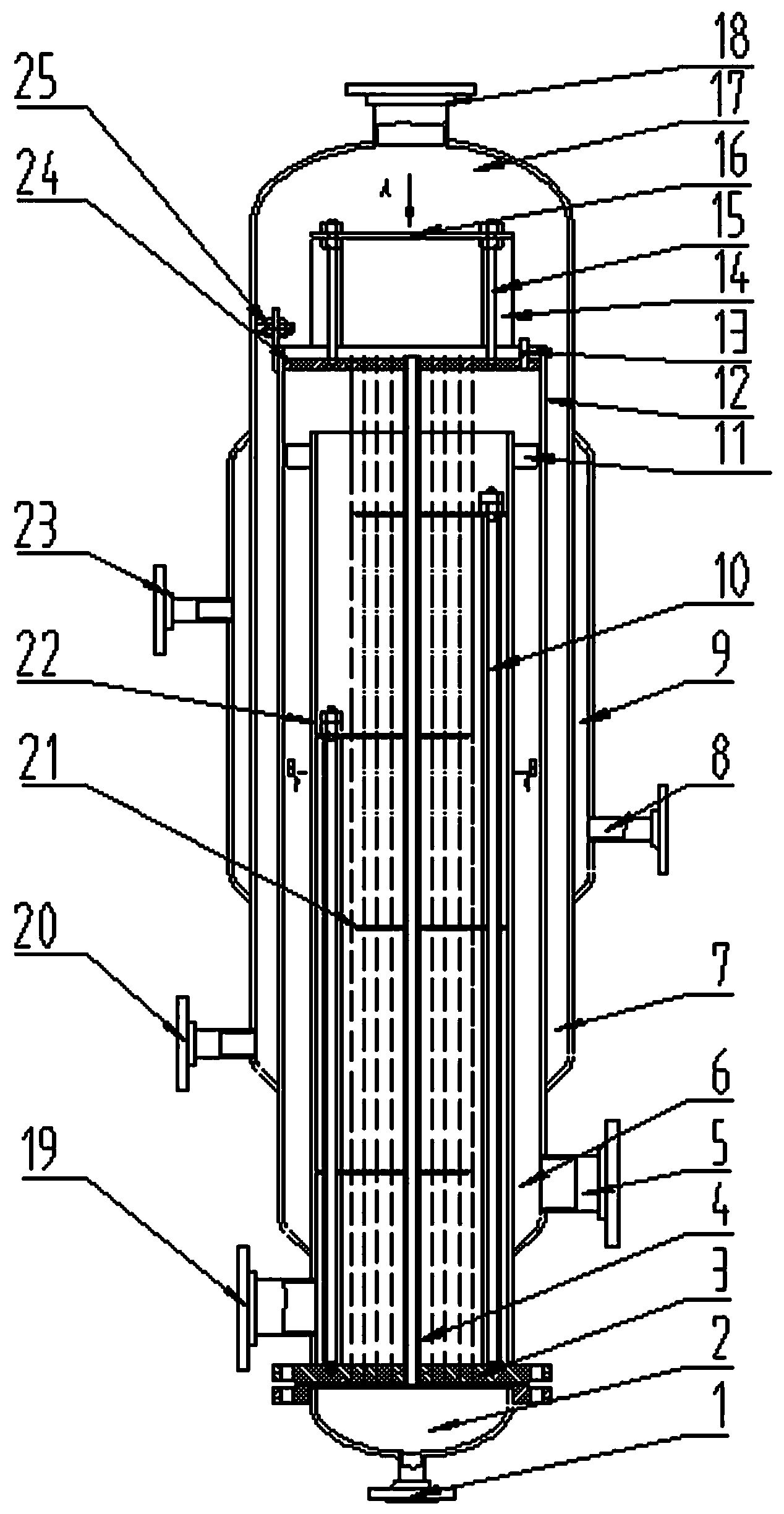

Integrated lifting film evaporation device

A technology of evaporation device and lifting film, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve the problems of affecting evaporation effect, low material recovery rate, short material evaporation time, etc., to improve gas-liquid separation efficiency, material High recycling rate and good material evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

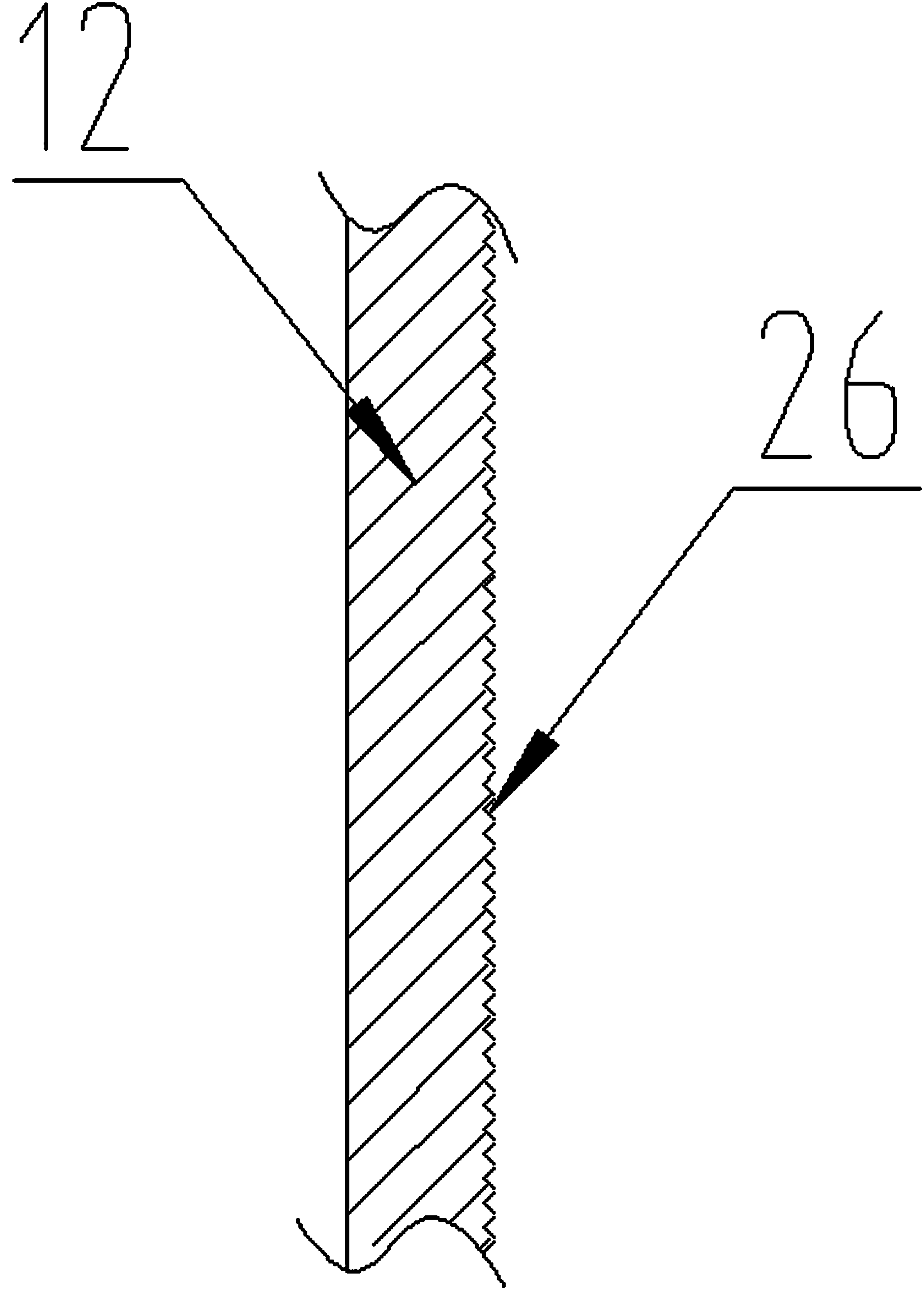

[0029] One side of the upper tube plate 24 of the present invention is provided with an exhaust hole 13 for exhausting gas in the cavity.

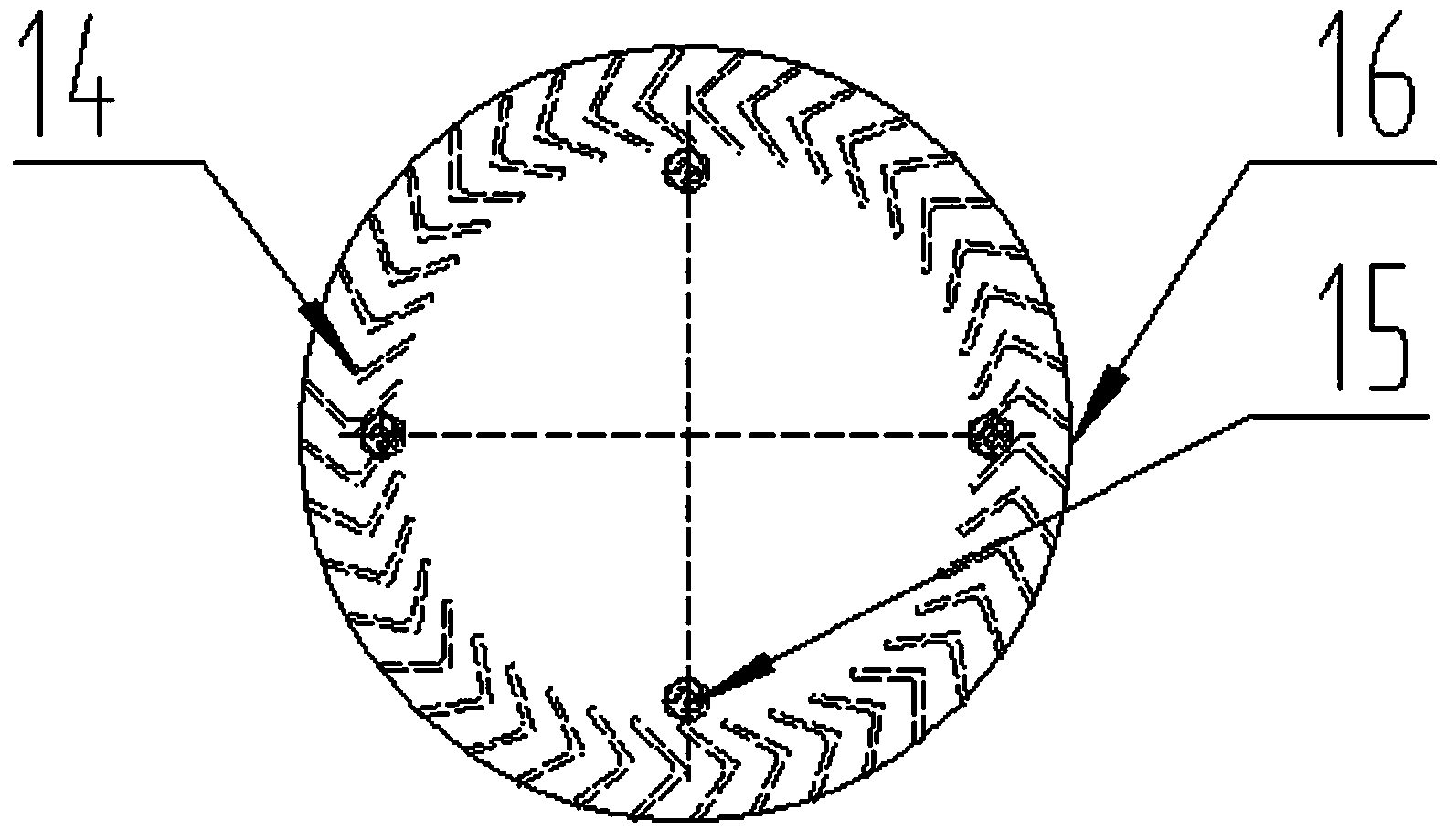

[0030] During operation, the heated heat transfer oil is circulated into the first heat transfer oil chamber 6 and the second heat transfer oil chamber 9, and then the pumped bubble point material enters the feed chamber 2 through the feed valve 1, and the material is evenly distributed in the feed chamber 2. Introduced into the evaporating tube bundle 4, the rising high-temperature airflow simultaneously drives the material to form a film along the tube wall of the evaporating tube bundle 4, and the high-temperature heat transfer oil infiltrated outside the evaporating tube bundle 4 continues to heat the material until it forms a gas-liquid mixture, and the high-temperature gas-liquid mixture is discharged Afterwards, it continuously impacts the circular plate 16 set on the top; a large amount of foam generated during the impact process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com