Heating device and evaporation device using same

A heating device and equipment technology, used in lighting and heating equipment, vacuum evaporation coating, sputtering coating and other directions, can solve problems such as uneven heating, achieve stable evaporation rate, improve accuracy, and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

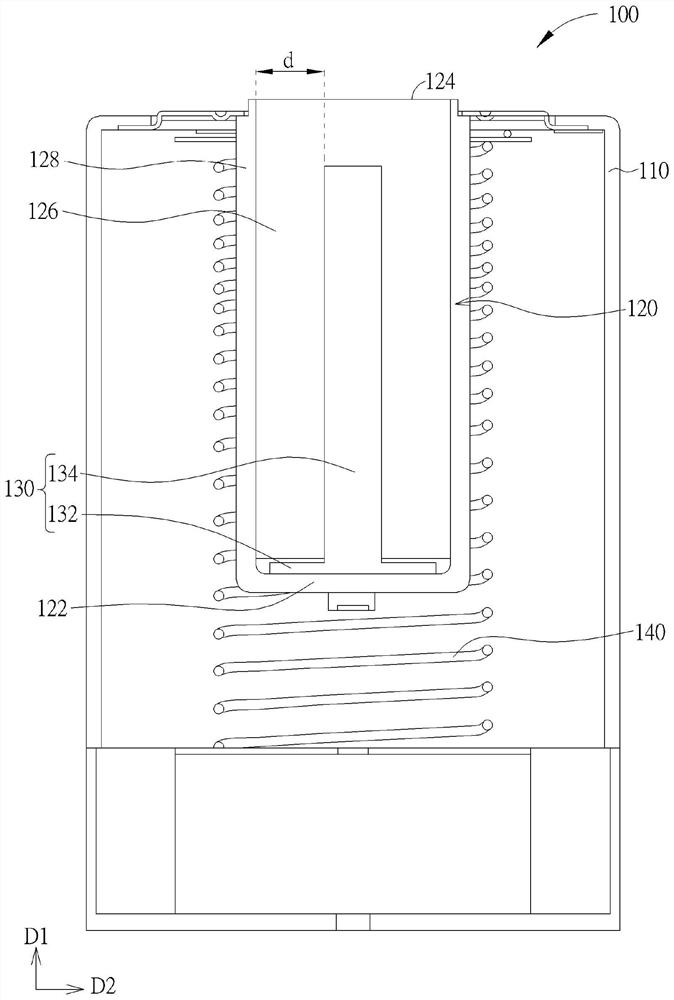

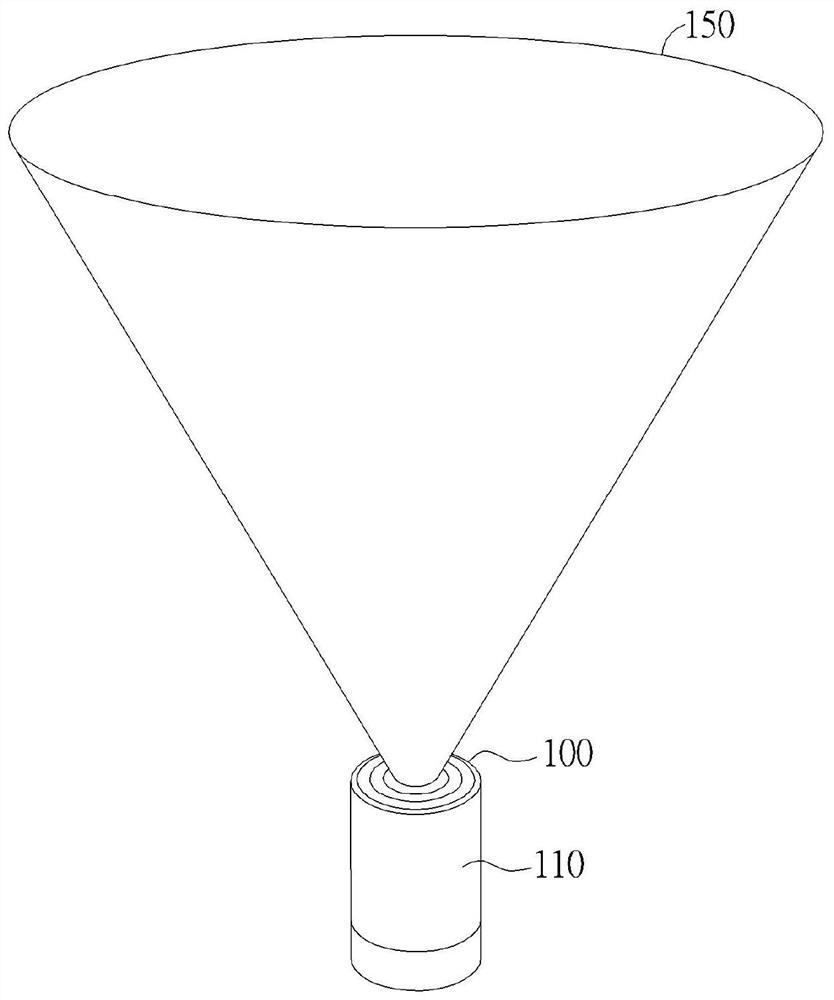

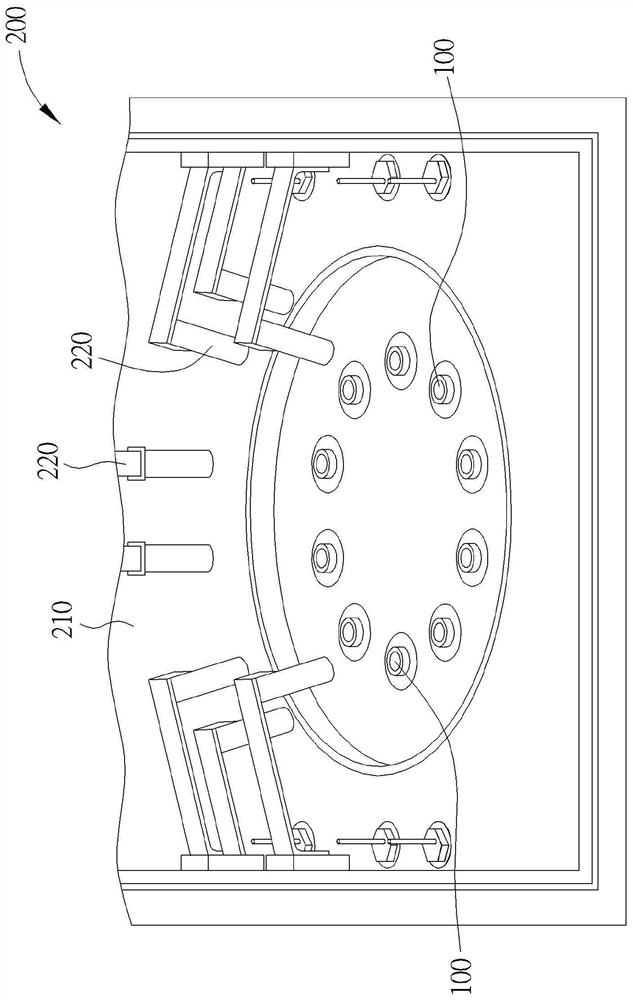

[0032] The present invention can be understood by referring to the following detailed description in conjunction with the drawings. It should be noted that, in order to make the readers easy to understand and the drawings are concise, the drawings of the present invention only draw at least a part of the heating device or the evaporation equipment and certain elements in the drawings are not drawn to actual scale. In addition, the quantity and size of each element in the drawings are only for illustration, and are not intended to limit the scope of the present invention.

[0033] Throughout this specification and the appended claims, certain terms will be used to refer to particular elements. Those skilled in the art should understand that evaporation equipment manufacturers or the industry may use different names to refer to the same component. This document does not intend to distinguish between those elements that have the same function but have different names. In the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com