Simplified powder feeding and vaporization apparatus

A technology of evaporation device and evaporator, which is applied in the direction of vacuum evaporation plating, metal material coating process, coating, etc., can solve the problems of unexpected main body and dopant material metering control, etc., to reduce the risk of degradation, high The effect of evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

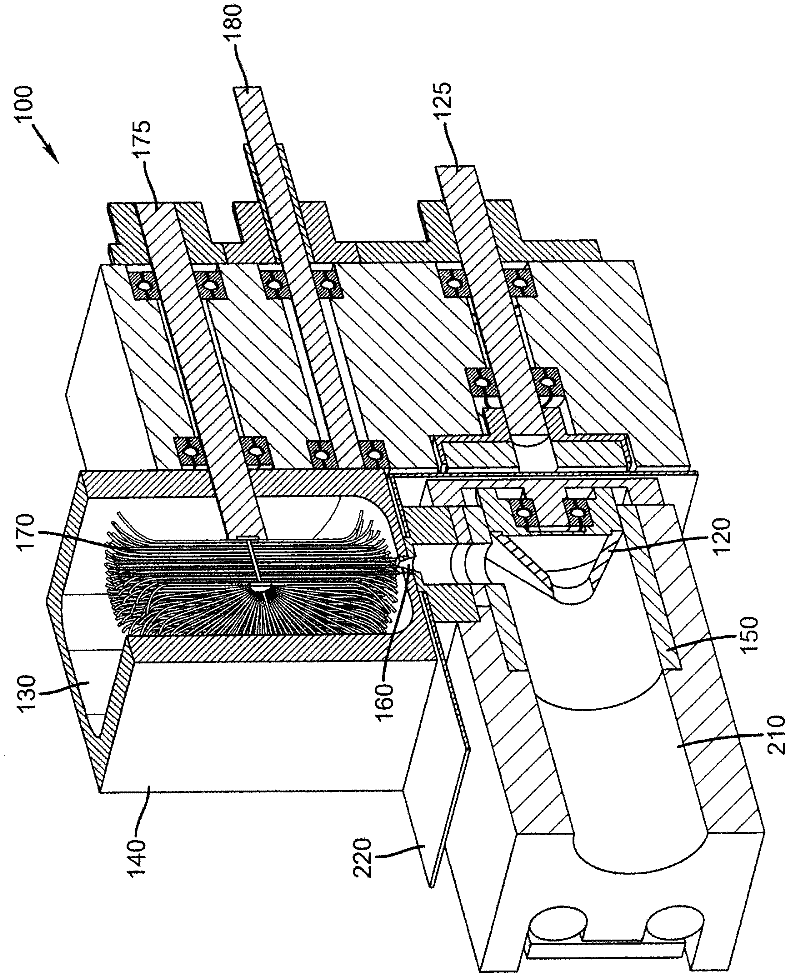

[0032] now turn image 3 , shows a three-dimensional cross-sectional view of an embodiment of a device according to the invention. The evaporation device 100 is a device for evaporating particulate material. The evaporation device 100 comprises a metering device comprising: a housing having a reservoir for containing particulate material; an opening in the reservoir for discharging material into the evaporation chamber; rotatable wire wheel brush in the brush. These components are described in more detail below. Reservoir 130 is located within housing 140 for containing particulate material. The particulate material may comprise a single component, or it may comprise two or more different material components, each material component having a different vaporization temperature. Although not shown, the reservoir 130 may also include larger storage and supply means located thereon to increase the volume of particulate material that may be loaded. Such containers and feeders ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com