Device and method for the joint feeding of plastic particles and a liquid into a purification device

A technology of plastic granules and purification devices, which is applied in the direction of cleaning methods using liquids, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of unusable purification devices, difficulty in continuous charging of purification devices, etc., and achieve simple energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Unless stated otherwise, the same reference numbers refer to the same objects in the figures.

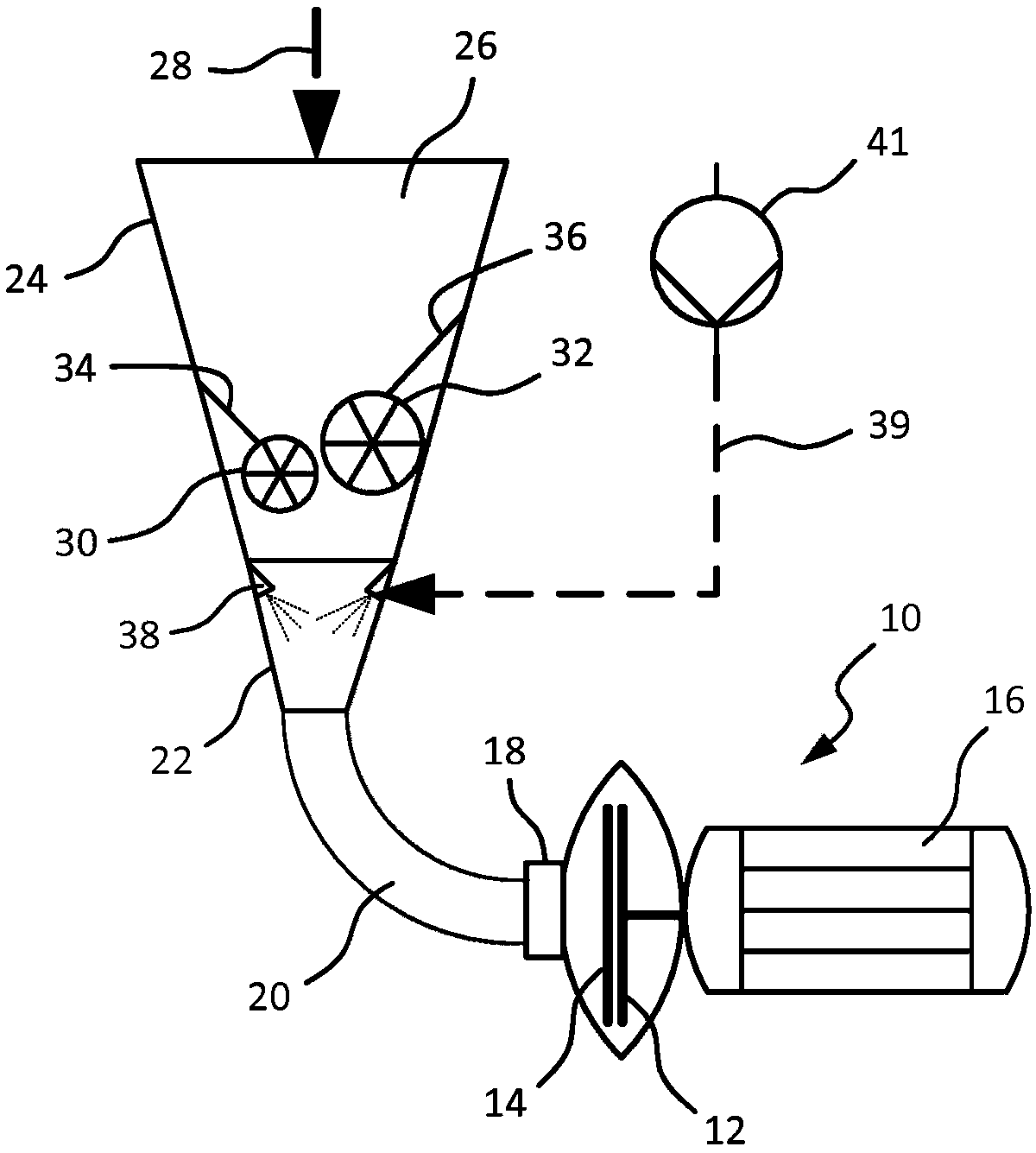

[0032] exist figure 1 10 shows a cleaning device for removing contaminants from plastic particles, for example plastic flakes. In the example shown, the cleaning device is a disc refiner, the cleaning discs of which are indicated with reference numerals 12 and 14 . At least one cleaning disk 12 , 14 is driven in rotation by a motor 16 . Such a device is known per se and can be designed as shown in WO 2013 / 010654 A2. Although in figure 1 A disc refiner is shown, but other purification devices are also possible, such as drum or conical refiners.

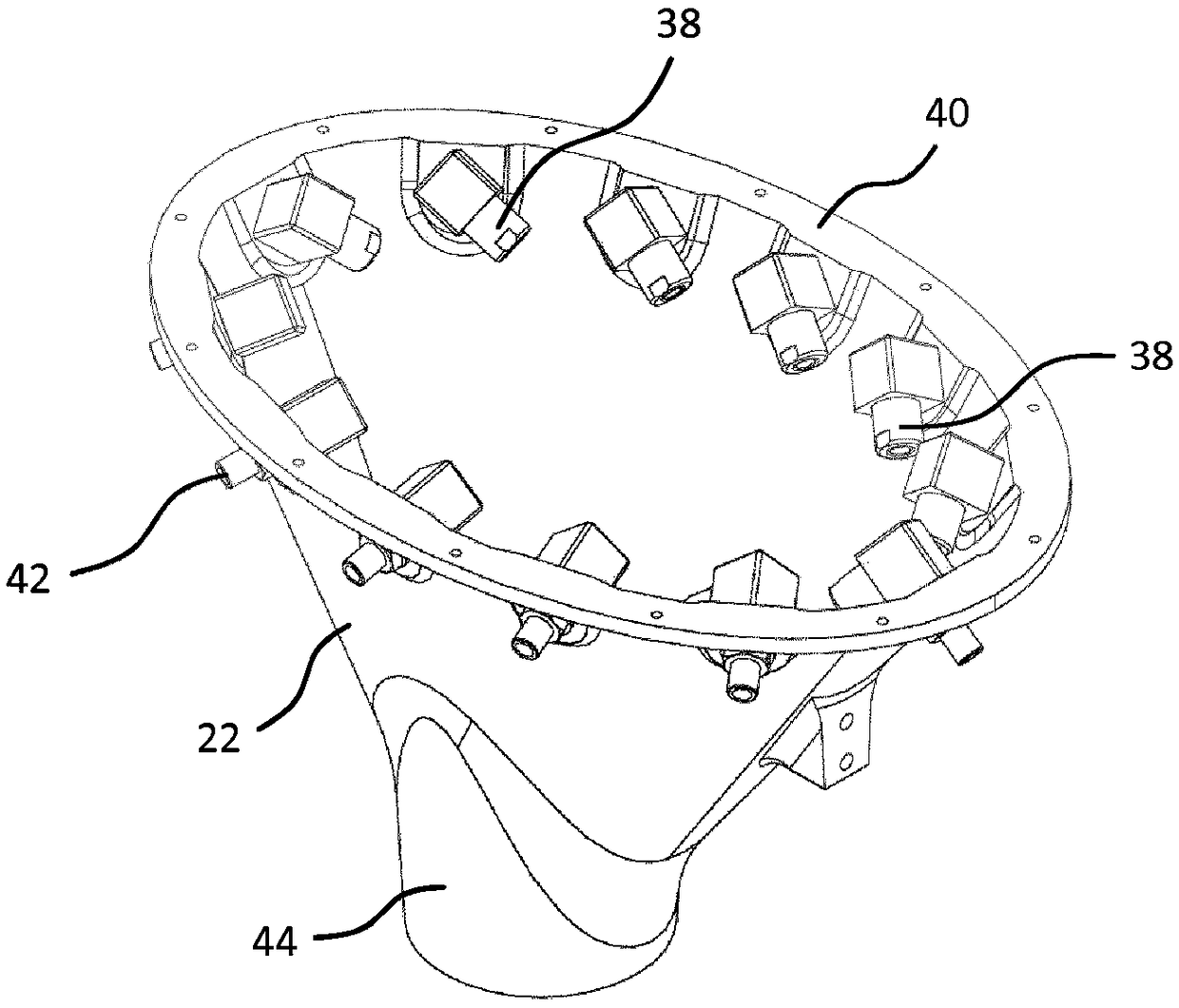

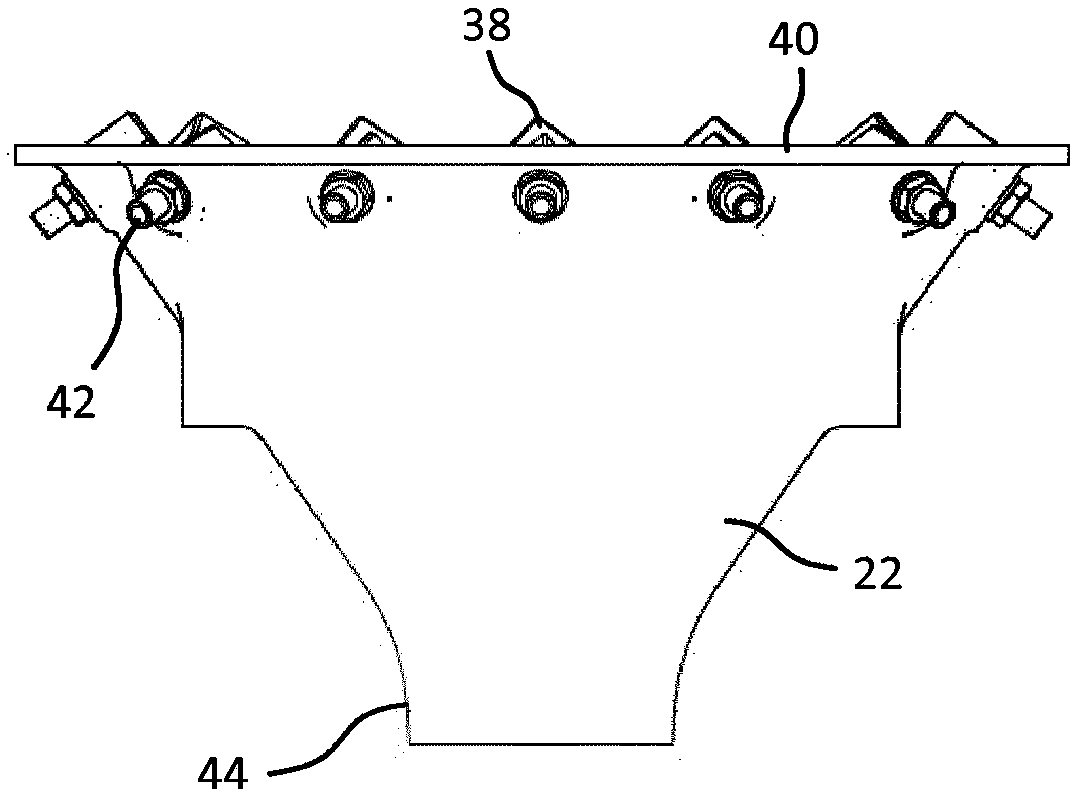

[0033] A line 20 is connected to the inlet 18 of the purification device 10 , said line being connected to the outlet of an input funnel 22 . Arranged above the inlet of the feed funnel 22 is a delivery funnel 24 which forms a delivery reservoir 26 into which the plastic particles to be cleaned are injected, as indicated graphica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com