Procedure for manufacturing an undershirt and undershirt obtained with this procedure

A sweater and construction technology, applied in the field of clothing, can solve the problems of processing time, high energy cost, wasting raw materials, slowing down production, etc., and achieve the effect of reducing time and labor costs, simplifying sewing and dyeing operations, and reducing manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

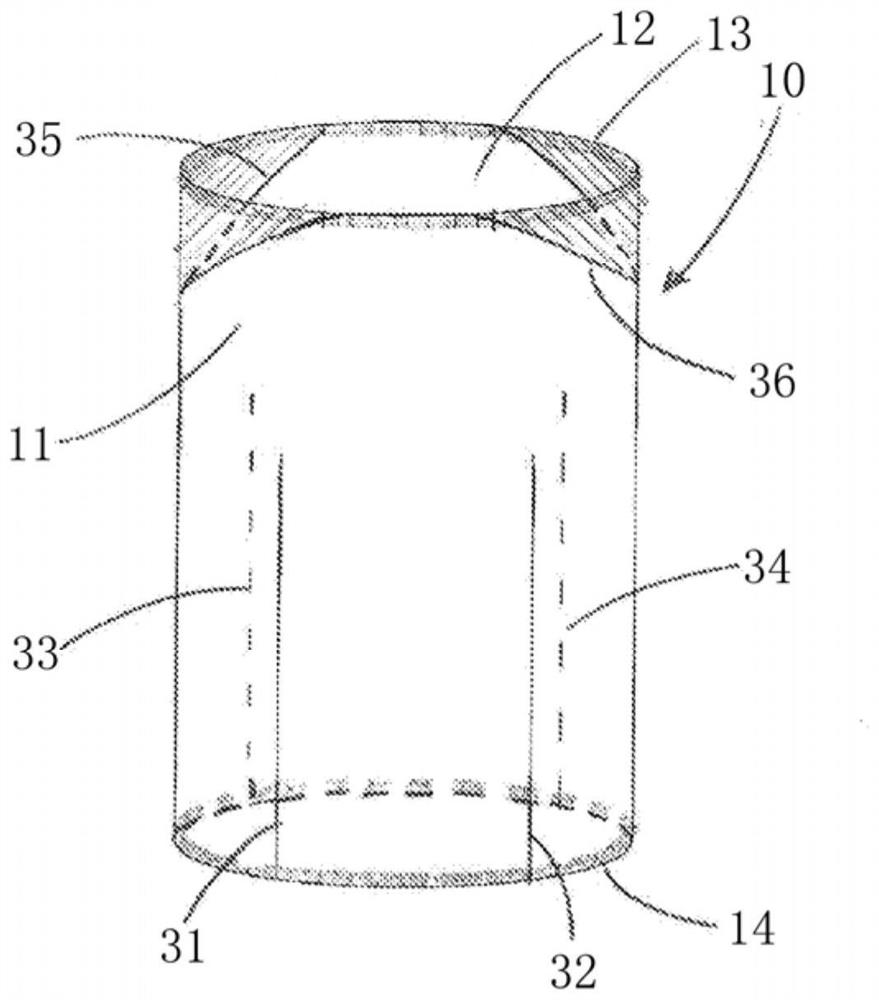

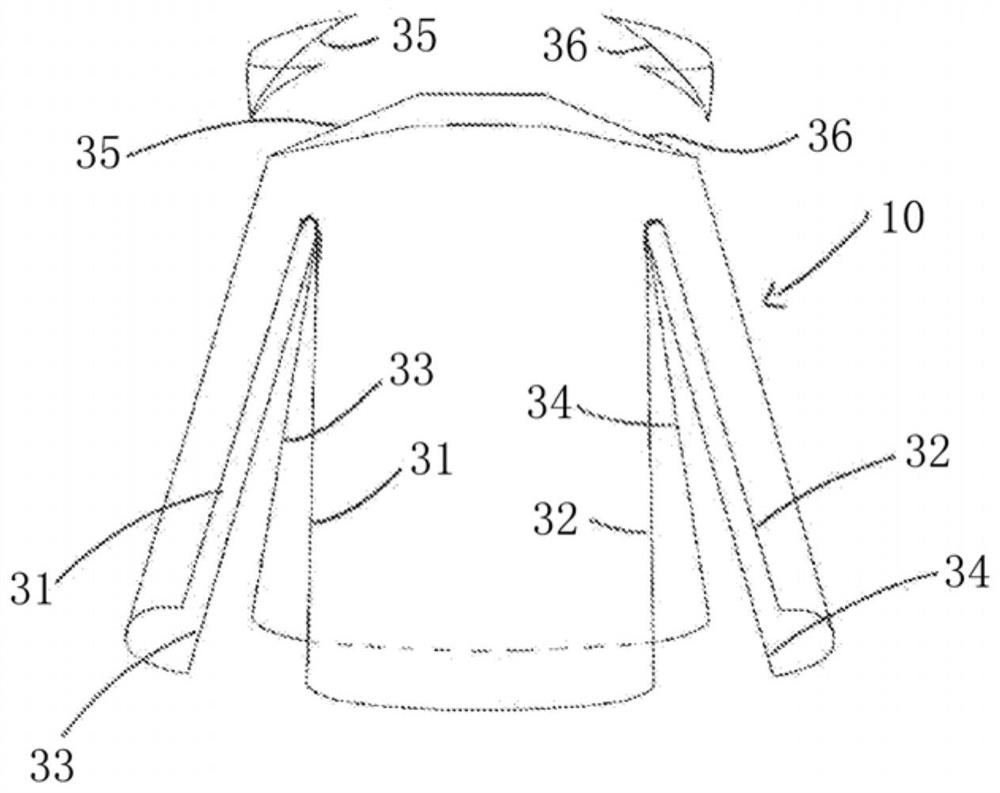

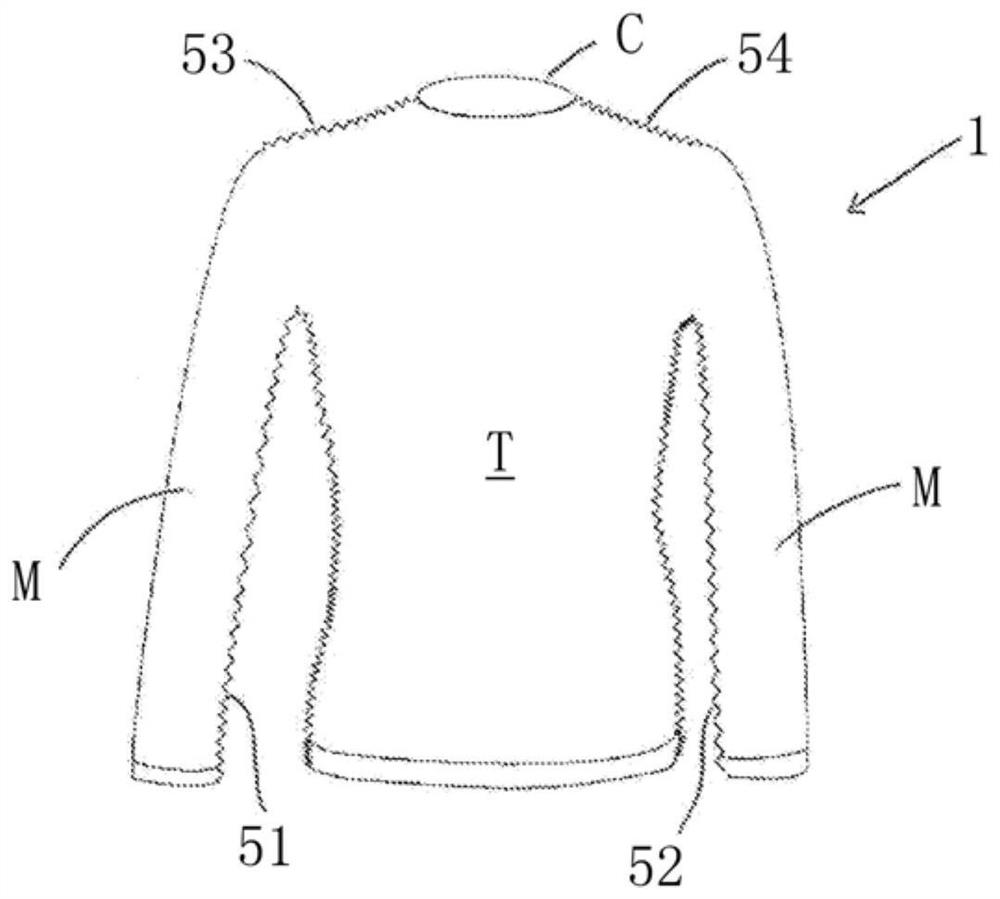

[0058] specific reference Figure 1A , Figure 1B and Figure 1C , these figures show three different steps of a method according to the invention for manufacturing an undershirt 1 of the type provided with a torso, two long sleeves and a collar.

[0059] The method involves the use of circular knitting machines utilizing seamless technology.

[0060] The first step of the method involves using said knitting machine to configure the first tubular element 10 as a cylindrical fabric.

[0061] For ease of description and with reference to the final garment, said first tubular element 10 comprises a front side 11 , a rear side 12 , an upper edge 13 and a lower edge 14 .

[0062] Said knitting machine interacts with a graphic program for designing garments, during the construction step of said first tubular element 10 , producing on said first tubular element 10 structured areas characterized by specific elasticity and compression ( not shown), and draw multiple cutting lines ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com