Wire feeding mechanism of vacuum film plating machine

A technology of vacuum coating machine and wire feeding mechanism, which is used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions to ensure production quality, improve square resistance uniformity, and ensure continuity and smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

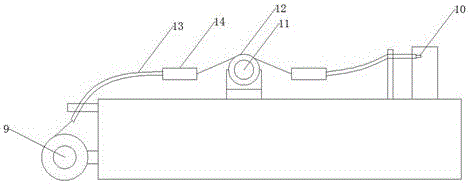

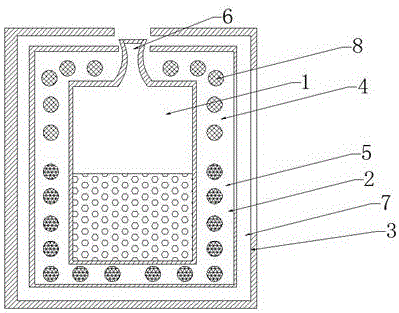

[0021] A wire feeding mechanism of a vacuum coating machine, comprising a wire feeding reel 9, a wire feeding mechanism, a wire outlet nozzle 10 and a heating crucible, the wire outlet nozzle 10 extending into the heating crucible, and the wire feeding mechanism including a wire feeding rotating shaft 11 , a number of wire feed rollers 12 fixed on the wire feed shaft 11, a power device that provides power for the wire feed shaft 11, the two ends of the wire feed roller 12 are provided with wire guards 13 and crimping blocks 14; the heating crucible An accommodating cavity 1 for accommodating heated materials, a heating cavity 2 surrounding the periphery of the accommodating cavity 1, and an outer wall 3 surrounding the heating cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com