Method for vaporizing fluidized organic materials

An organic substance and fluidization technology, applied in vacuum evaporation coating, coating, sputtering coating, etc., can solve problems such as changes in the geometry of steam pipes, reduce the risk of decomposition, stabilize evaporation rate, and stabilize heating The effect of device temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

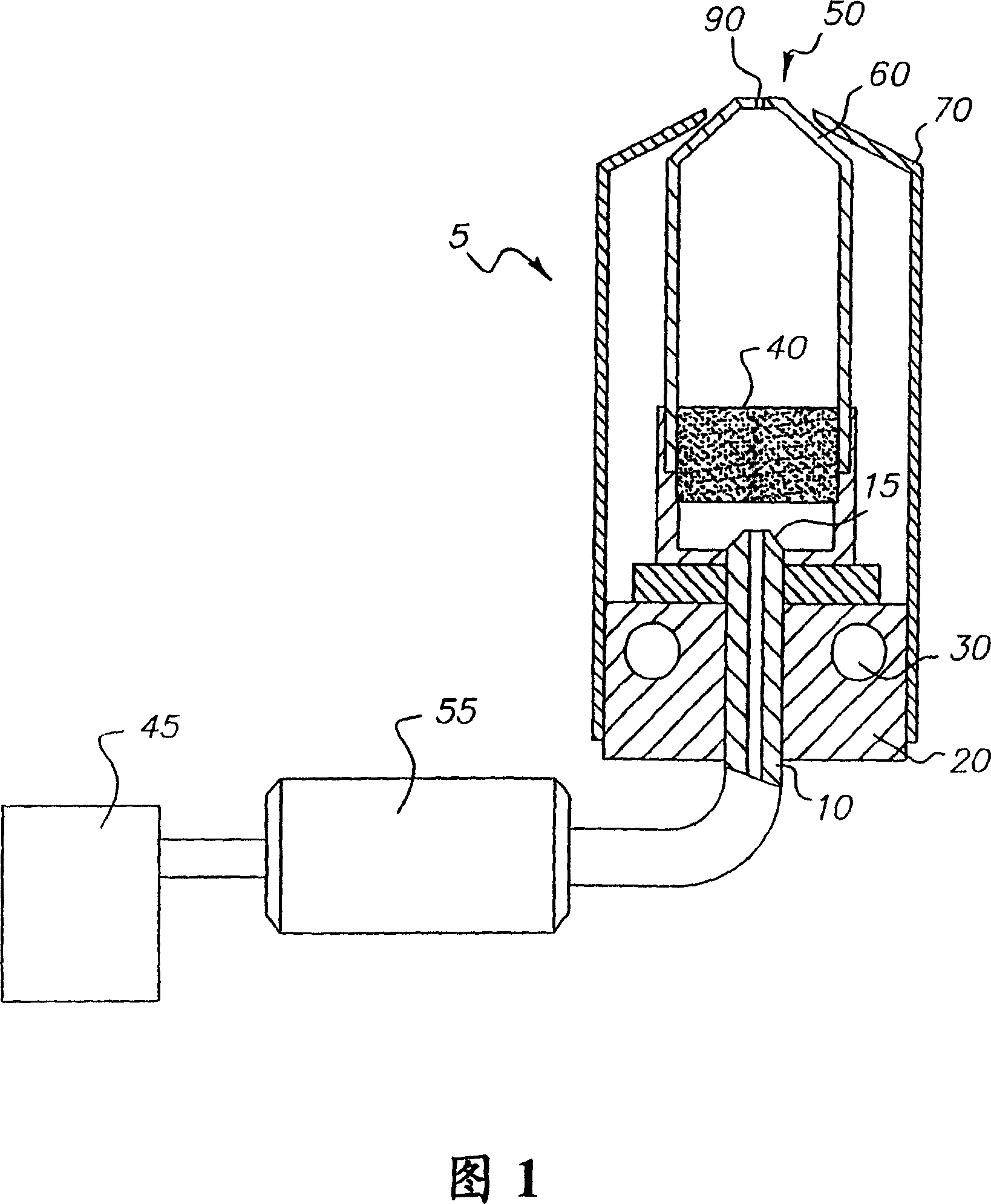

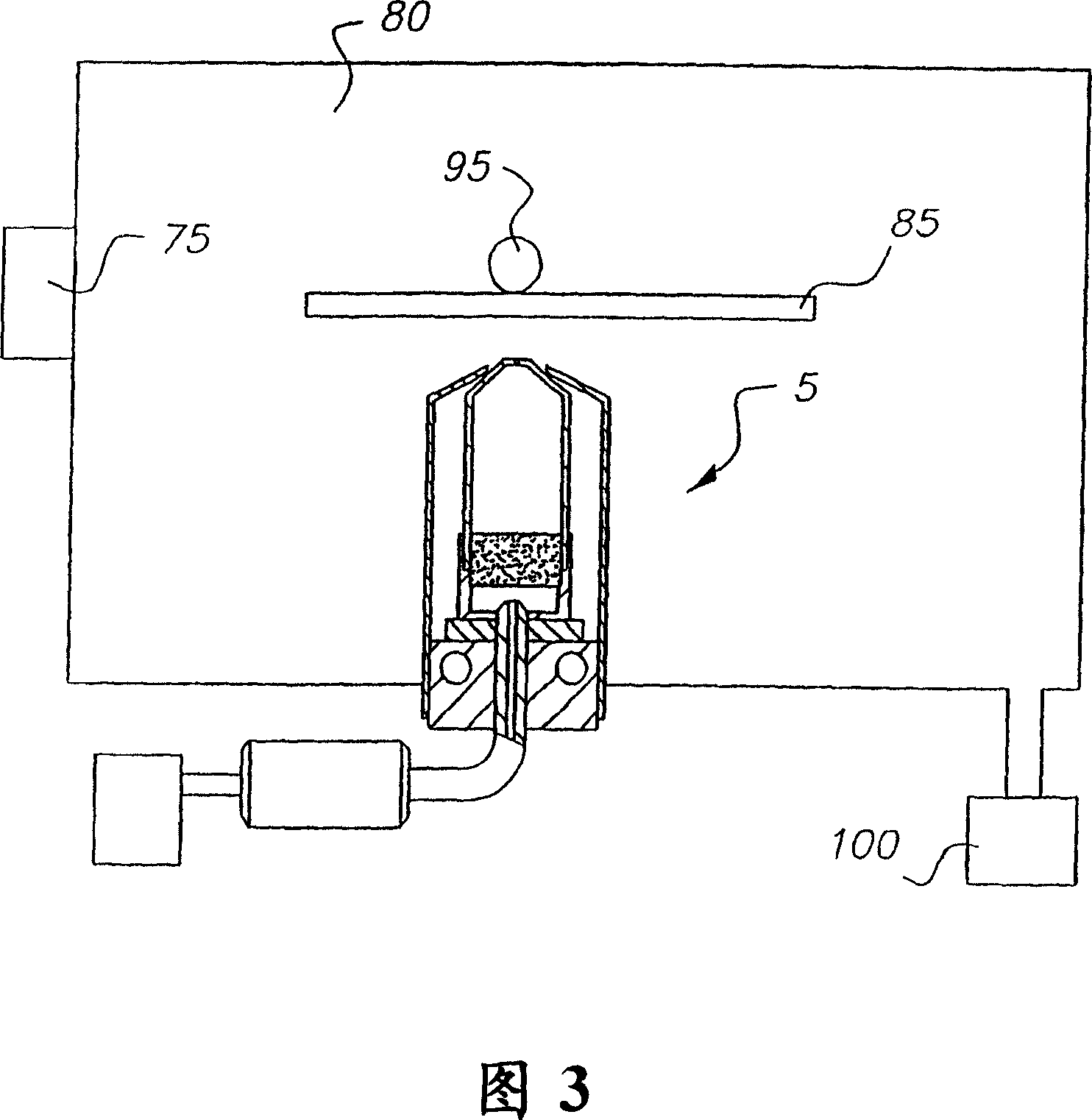

[0028] Reference is now made to Figure 1 which shows a cross-sectional view of one embodiment of the device of the present disclosure. The evaporation device 5 is a device for evaporating organic substances to the surface of the substrate to form a thin film, and includes a permeable first member 40, a pipe 60, and a metering device, which refers to the organic substance in the form of fluidized powder or provides fluidization. The powder form of the organic substance is measured, and the fluidized powder flow is directed to the device of the permeable first part 40. The permeable first part 40 may be part of the pipe 60. The pipe 60 also includes one or more holes 90. The evaporation device 5 also includes one or more protective covers 70.

[0029] In one embodiment, the container 45 is a container that receives a certain amount of organic matter in powder form. In this embodiment, the metering valve 55 includes a device for fluidizing the organic substance and metering the organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com