Application of copper pollution prevention synergist to improvement of copper pollution prevention performance of nylon flame-retardant material

A technology for flame retardant materials and copper pollution, which is applied in the fields of improving the anti-copper pollution performance of nylon flame retardant materials and anti-copper pollution synergists, can solve problems to be improved, and achieve easy industrialized large-scale production, slowing down the formation of copper ions, Prepare simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

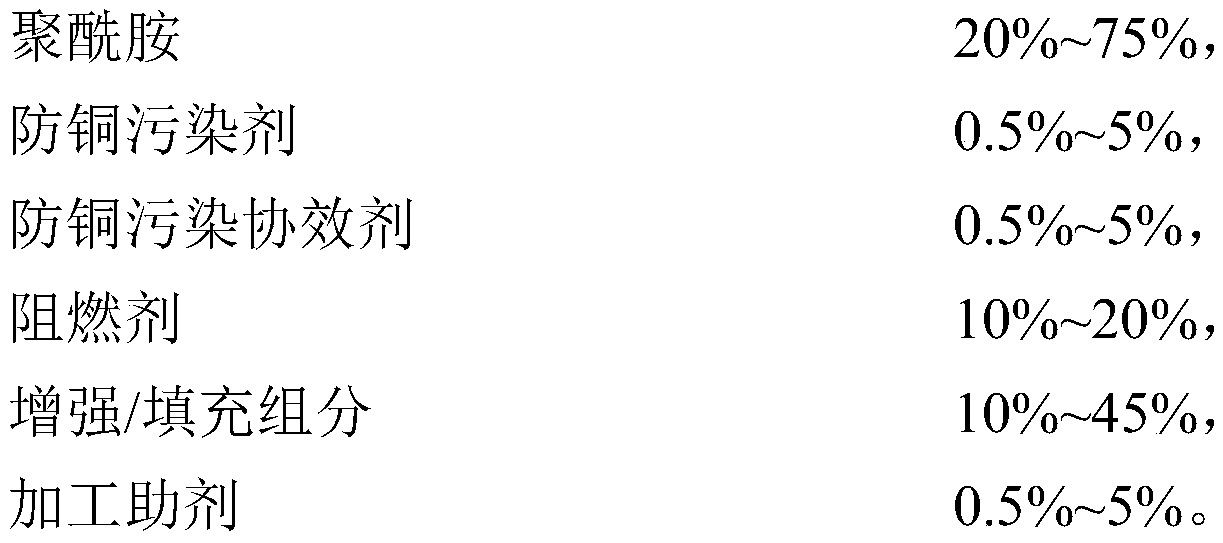

[0045] Use the following weights of ingredients:

[0046]

[0047] Mix polyamide, reinforcing / filling components and processing aids evenly, and feed them into the twin-screw extruder from the main feed, and then mix the flame retardant, anti-copper pollution agent and anti-copper pollution synergist evenly, and feed them from the side Add the twin-screw extruder, and after extruding, drawing, cooling, pelletizing and drying, the nylon flame-retardant material that prevents copper pollution can be obtained. Among them, the aspect ratio of the twin-screw extruder is 36:1, and the temperature of each section of the screw is: the temperature of each working section from the first barrel to the eighth barrel is 265±5°C, 265±5°C, 265°C ±5℃, 265±5℃, 245±5℃, 245±5℃, 245±5℃, 225±5℃, the temperature of the head is 255±5℃.

Embodiment 2

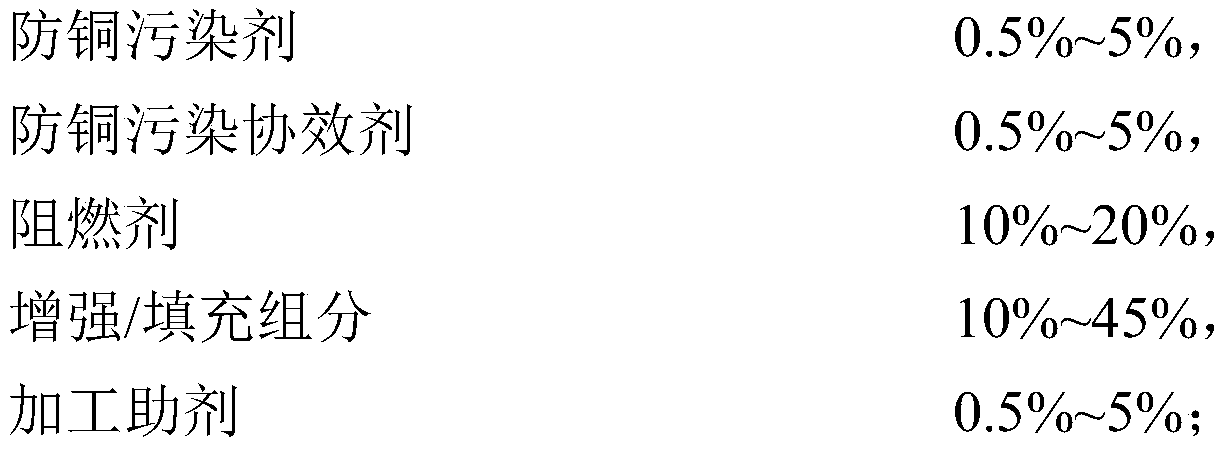

[0049] Use the following weights of ingredients:

[0050]

[0051] The preparation method of the nylon flame-retardant material that prevents copper pollution is the same as in Example 1. The temperature of each section of the screw is: the temperature of each working section from the first barrel to the eighth barrel is 260±5°C, 260±5°C, 260±5°C, 250±5°C, 230±5°C, 230±5°C 5°C, 230±5°C, 230±5°C, the temperature of the machine head is 260±5°C.

Embodiment 3

[0053] Use the following weights of ingredients:

[0054]

[0055]

[0056] The preparation method of the nylon flame-retardant material that prevents copper pollution is the same as in Example 1. The temperature of each section of the screw is: the temperature of each working section from the first barrel to the eighth barrel is 240±5°C, 240±5°C, 240±5°C, 230±5°C, 230±5°C, 230±5°C 5°C, 230±5°C, 230±5°C, the temperature of the machine head is 230±5°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com