Vacuum coating machine evaporation crucible

A vacuum coating machine and crucible technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of material splashing, uneven heating of evaporated material, etc., to avoid condensation and realize evaporation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

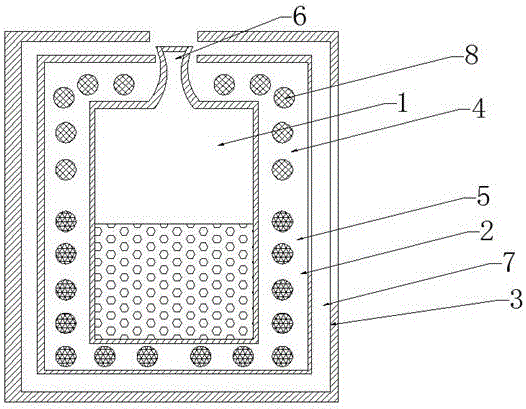

[0018] An evaporation crucible of a vacuum coating machine, comprising a housing chamber 1 for accommodating heated materials, a heating chamber 2 surrounding the periphery of the housing chamber 1, and an outer wall 3 surrounding the heating chamber 2, the heating chamber 2. In order from top to bottom, there are upper heating unit 4 for ensuring that the temperature of the evaporation port of the crucible is higher than the freezing point of the evaporation material and independent temperature control, and a lower heating unit 5 located on the periphery of the crucible for independent temperature control. The top of the heating chamber 2 There is a flow channel 6 for the heated material to pass through, the top of the flow channel 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com