A kind of preparation method and application of highly volatile composite ligand barium precursor salt

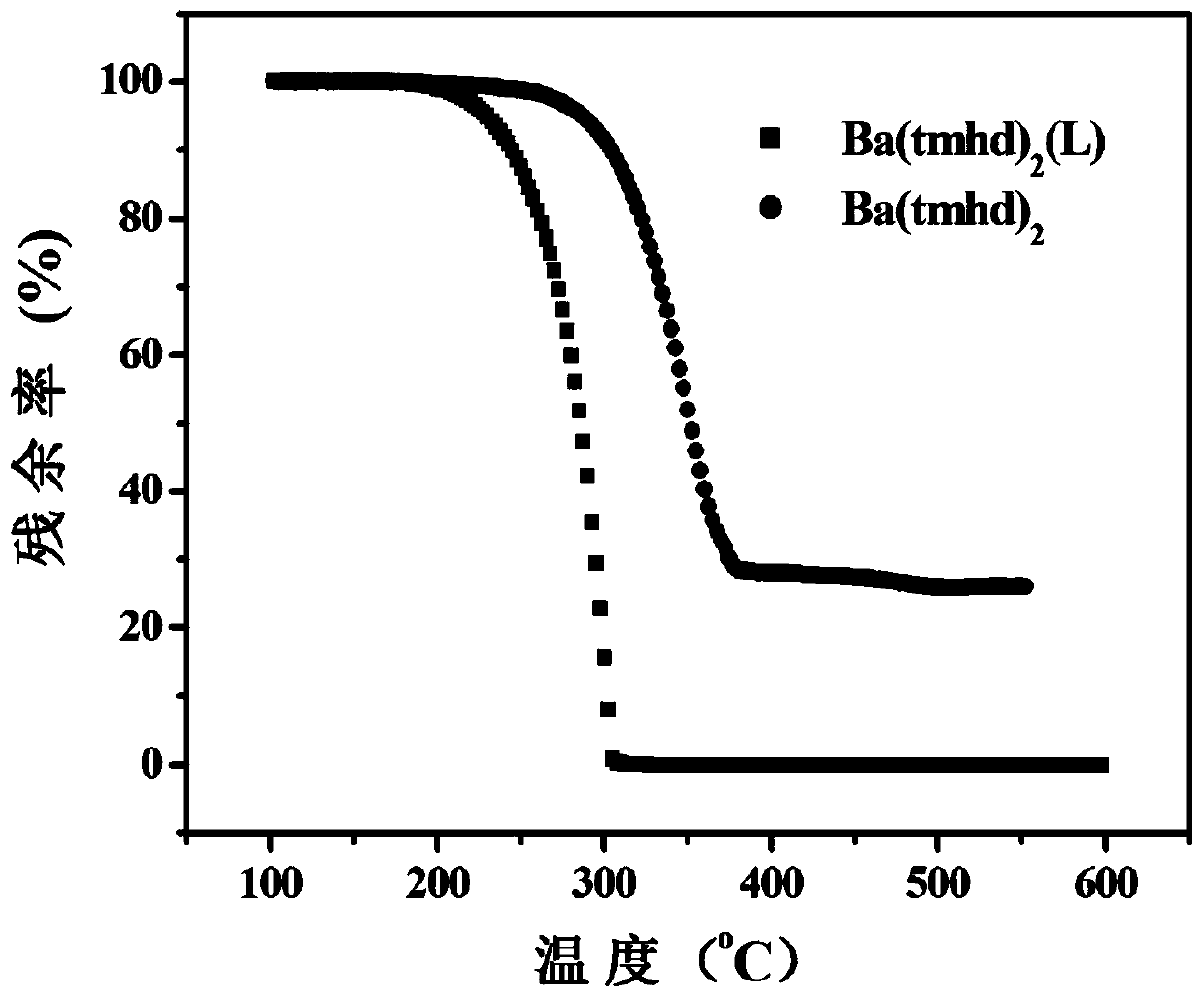

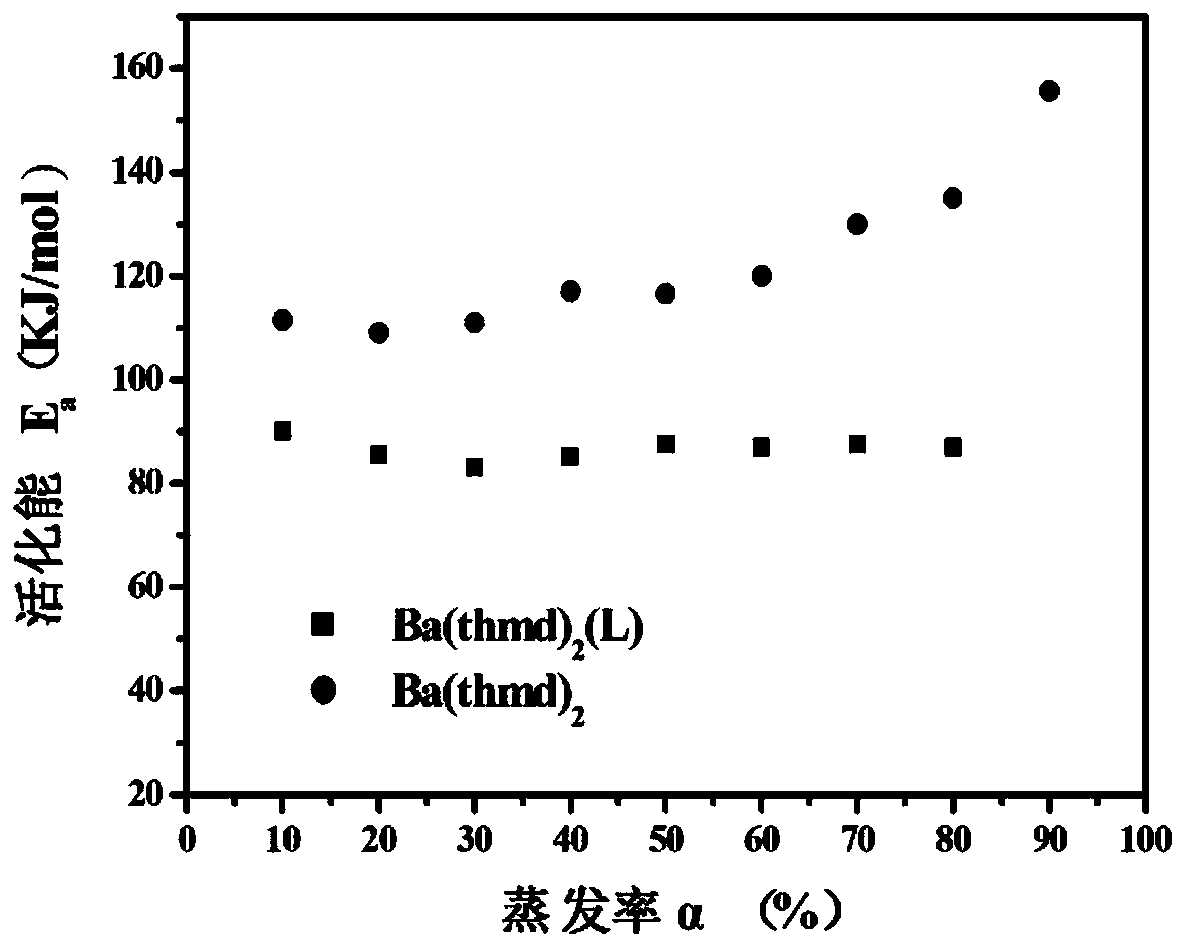

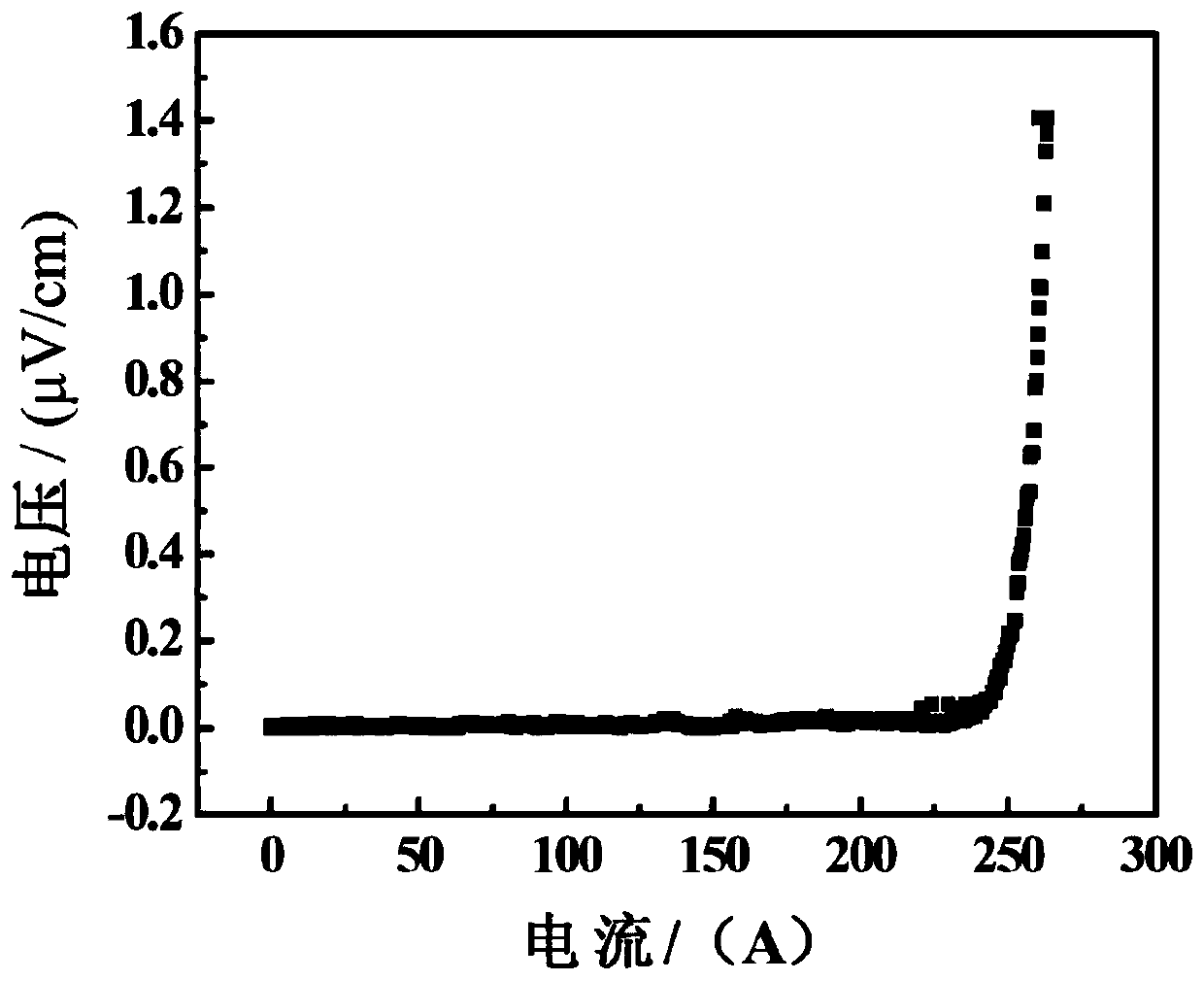

A technology with high volatility and ligands, which is applied in the usage of superconductor elements, chemical instruments and methods, cable/conductor manufacturing, etc., can solve the problems of volatility and poor thermal stability of metal barium precursor salts, and achieve excellent superconductivity , The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of a high volatility composite ligand barium precursor salt, comprising the following steps:

[0034] A, first join metal barium and dry organic solvent in the glass there-necked flask, then feed nitrogen, and the glass there-necked flask is provided with a condenser tube, a drying tube and a nitrogen gas inlet conduit;

[0035] B. Mix 2,2,6,6-tetramethyl-3,5-heptanedione and an organic solvent evenly to form a mixed solution;

[0036] C, first slowly drop the mixed solution described in the step B into the there-necked flask described in the step A, then react under the airtight conditions of anhydrous and oxygen-free, until the metallic barium disappears completely;

[0037] D, fluorinated bis-trifluoromethanesulfonimide auxiliary ligand L is dissolved in dry organic solvent two, forming mixed solution two;

[0038] E, first slowly drop the mixed solution two described in the step D into the glass there-necked bottle described in the step C, then...

specific Embodiment

[0052] In a 2000 ml three-necked flask equipped with a condenser tube, a drying tube and a nitrogen gas inlet conduit, 6.85 g of metal barium particles and 700 ml of dry n-pentane were sequentially added, and 18.4 g of 2,2,6,6 - Tetramethyl-3,5-heptanedione (β-diketone, tmhd) and 184 ml of n-pentane were mixed uniformly to form a mixed solution.

[0053] The above mixed solution was slowly added dropwise into the three-necked flask through a normal pressure dropping funnel, and under anhydrous and oxygen-free airtight conditions, the reaction was vigorously stirred at 30°C until the metal barium particles completely disappeared; then, 140 ml containing 14.1 g The chloroform solution of fluorinated bistrifluoromethanesulfonimide was slowly added dropwise into a glass three-necked flask, under anhydrous and oxygen-free airtight conditions, mixed and stirred at 60°C for 12 hours, and then the solvent was distilled off under reduced pressure through a rotary evaporator. , vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com