Crucible type evaporator source used for organic electrofluorescence type film plating machines

A technology of luminescence and coating machine, applied in the field of evaporation source, can solve the problems of troublesome operation, short life of evaporation source, low voltage, etc., and achieve the effect of convenient filling and refueling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

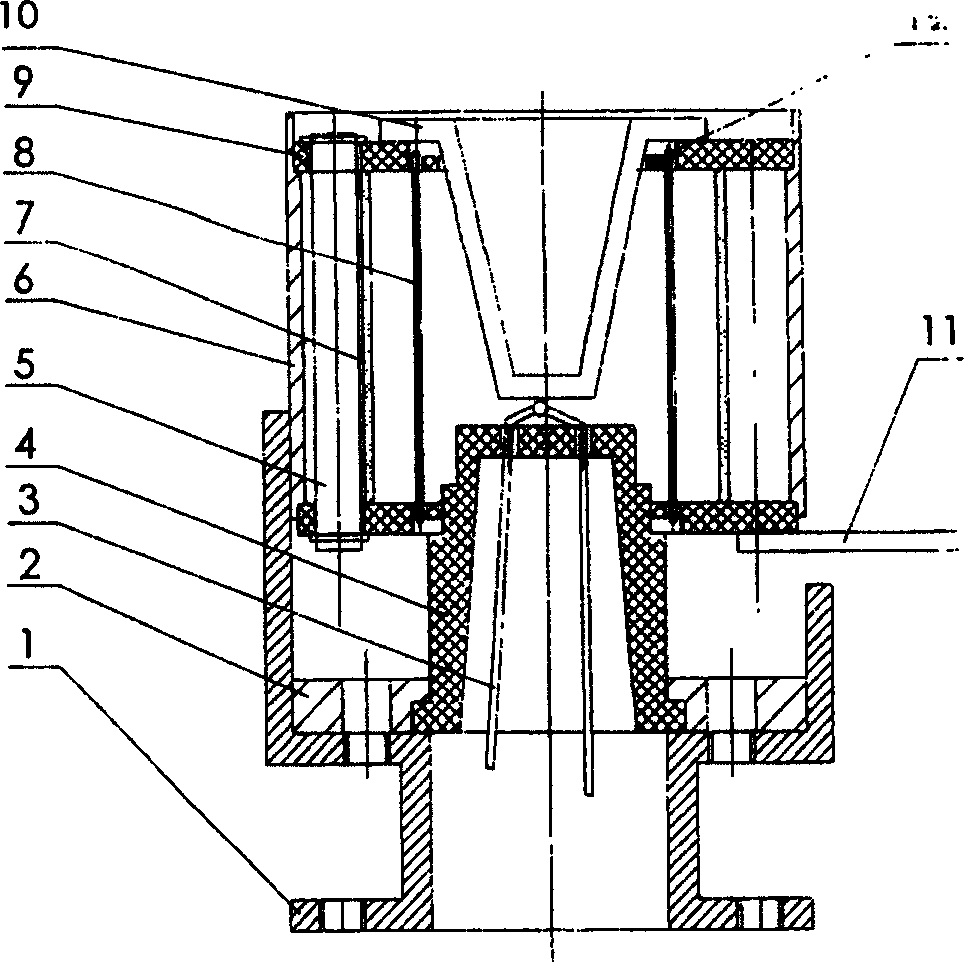

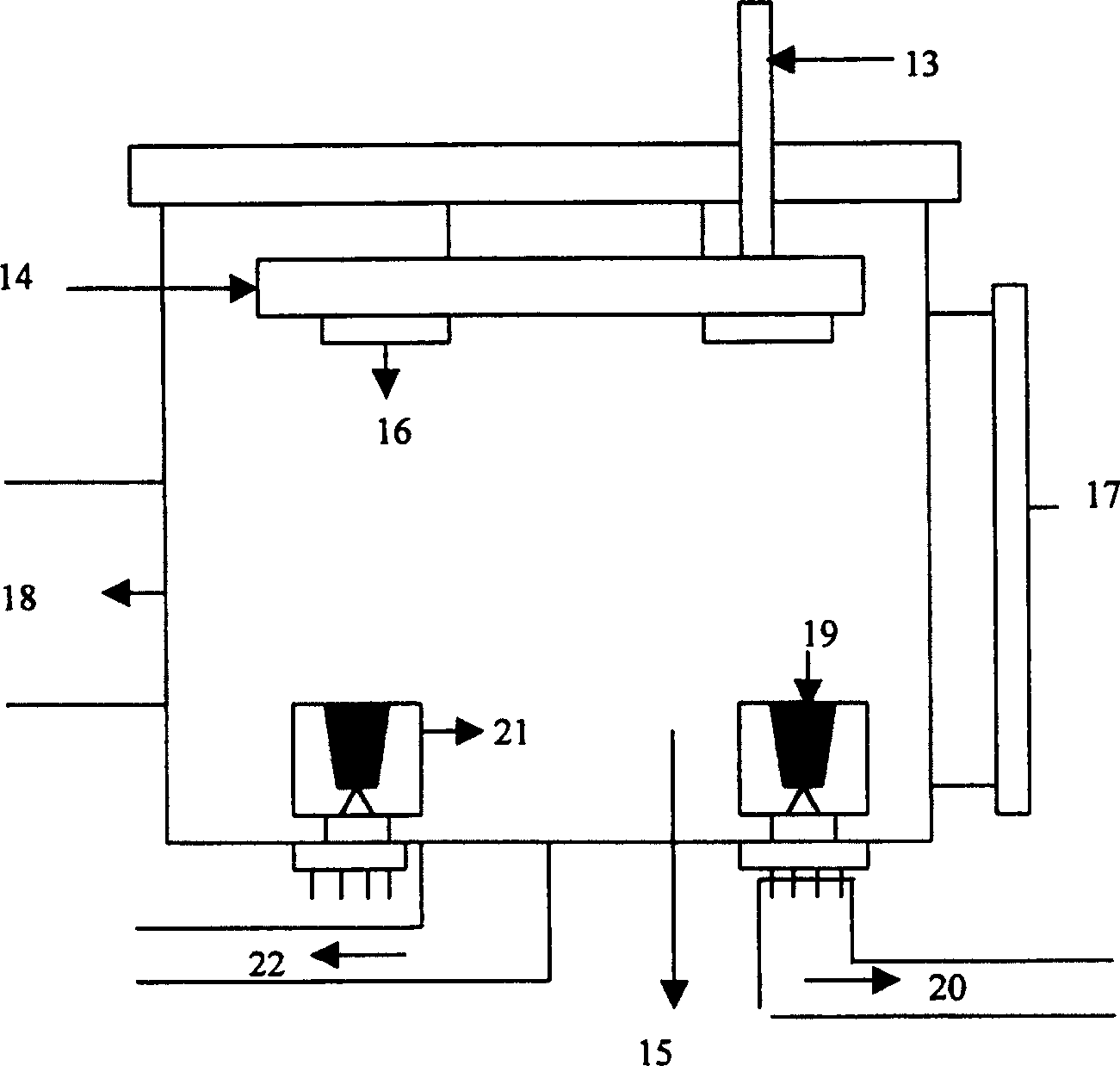

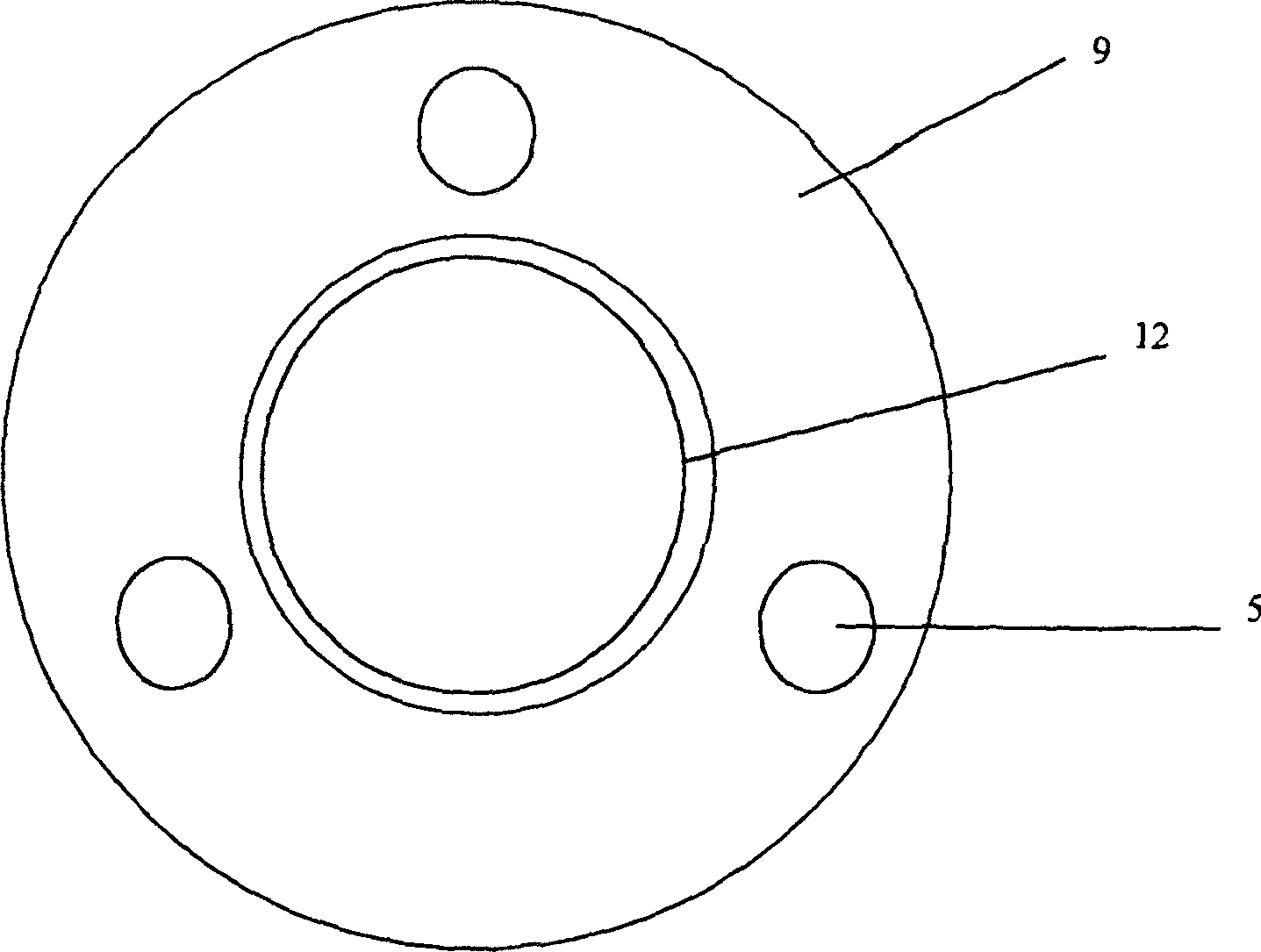

Embodiment Construction

[0014] The following takes the growth process of a double-layer green OLED device as an example to illustrate the use of the crucible-type evaporation source of the organic electroluminescence coating machine.

[0015] The material is ITO / NPB(60nm) / Alq(40nm) / Al(100nm), the steps are as follows:

[0016] 1. Load the used organic materials (Alq and NPB) into a quartz crucible;

[0017] 2. Put the crucibles with Alq and NPB into No. 3 and No. 4 furnaces of this equipment respectively. There are 5 furnaces in the equipment, which are respectively marked as No. 1-5 furnaces;

[0018] 3. Fix the processed ITO glass sheet to the substrate holder;

[0019] 4. Fix the substrate holder on the rotating system in the equipment through the slot;

[0020] 5. Close the large baffle below the substrate and the small baffle above the crucible;

[0021] 6. Close the opening of the system and turn on the mechanical pump to draw a low vacuum;

[0022] 7. When the vacuum reaches 100Pa, turn on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com