A three-dimensional integrated light-to-heat conversion material and its preparation method

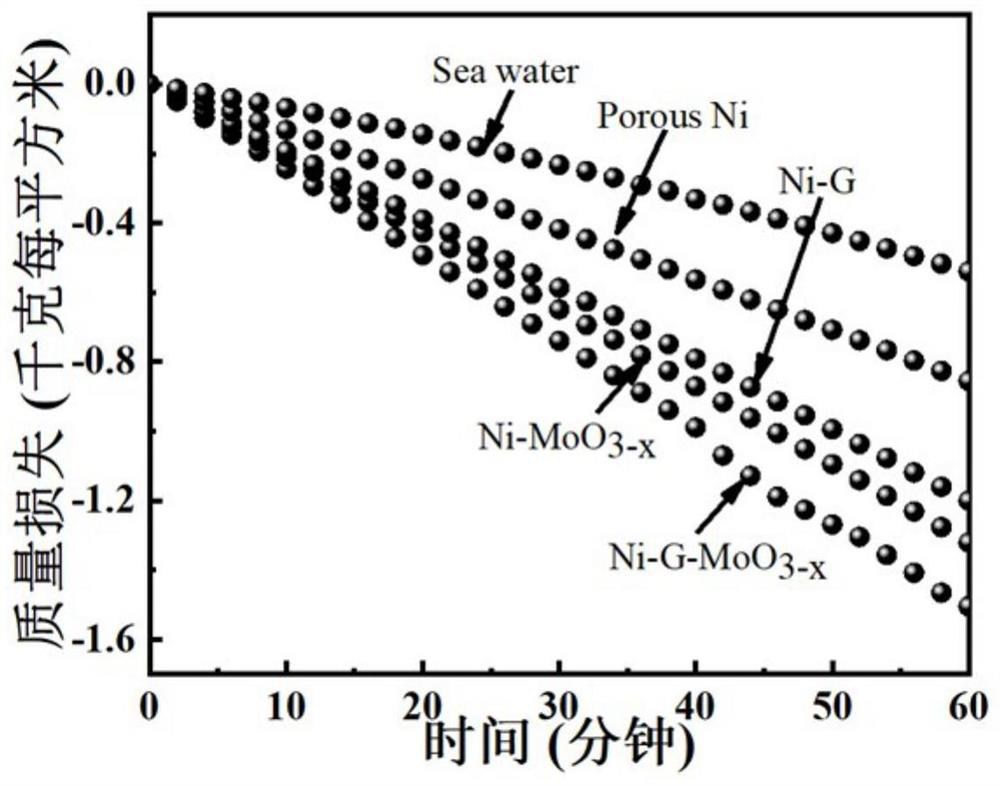

A photothermal conversion material and integrated technology, applied in chemical instruments and methods, metal material coating process, general water supply saving, etc., can solve problems such as inappropriate photothermal seawater desalination, uneven graphene growth, and complex preparation. , to achieve the effect of excellent self-cleaning ability, stable evaporation rate and fast preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

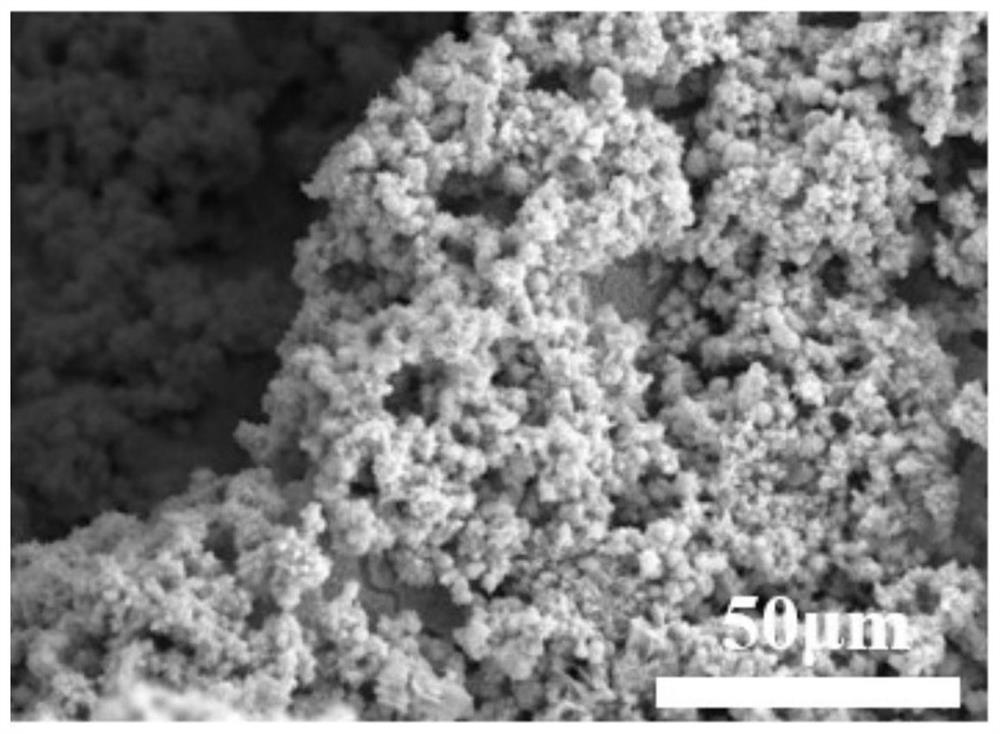

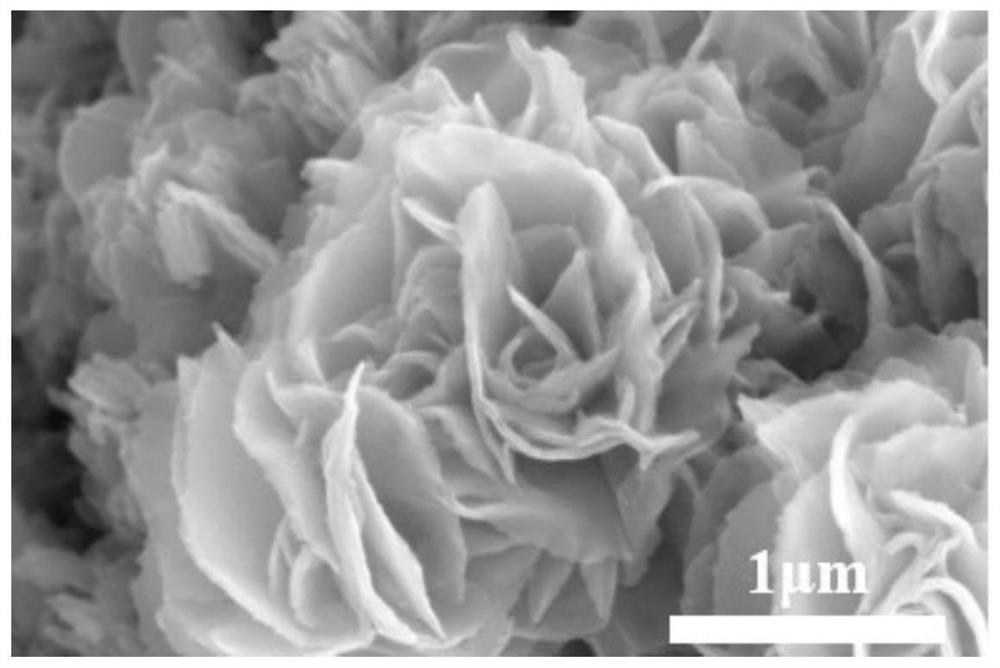

[0031] Preparation process in embodiment 1 is:

[0032] The first step: nickel foam pretreatment

[0033]Sonicate 3*3cm nickel foam in dilute hydrochloric acid (3mol / L), acetone, absolute ethanol, and deionized water for 5 minutes respectively.

[0034] The second step: CVD growth of graphene

[0035] First, put nickel foam into a tube furnace and heat it to 1035°C at 10°C / min under an atmosphere of argon (300sccm); secondly, heat-preserve and anneal foamed nickel at a temperature of 1035°C and a mixed atmosphere of argon (50sccm) and hydrogen (50sccm) 15 minutes; after the annealing is completed, the gas atmosphere in the tube furnace remains unchanged, and the temperature drops to 1000°C; after reaching the growth temperature of 1000°C, methane is introduced as a carbon source, and the mixed gas in the tube furnace becomes 20sccm hydrogen, 50sccm Argon and 100 sccm methane, incubation for 20 minutes. After the growth is completed, stop feeding hydrogen and methane, and sl...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is that the hydrothermal time reduces, specifically as follows:

[0043] The first step: nickel foam pretreatment

[0044] Nickel foam was ultrasonically treated in dilute hydrochloric acid (3mol / L), acetone, absolute ethanol and deionized water for 5 minutes respectively.

[0045] The second step: CVD growth of graphene

[0046] First, put nickel foam into a tube furnace and heat it to 1035°C at 10°C / min under an atmosphere of argon (300sccm); secondly, heat-preserve and anneal foamed nickel at a temperature of 1035°C and a mixed atmosphere of argon (50sccm) and hydrogen (50sccm) 15 minutes; after the annealing is completed, the gas atmosphere in the tube furnace remains unchanged, and the temperature drops to 1000°C; after reaching the growth temperature of 1000°C, methane is introduced as a carbon source, and the mixed gas in the tube furnace becomes 20sccm hydrogen, 50sccm Argon and 100 sccm methane, incubation ...

Embodiment 3

[0053] The difference between embodiment 3 and embodiment 1-2 is to reduce the hydrothermal time again, specifically as follows:

[0054] The first step: nickel foam pretreatment

[0055] Nickel foam was ultrasonically treated in dilute hydrochloric acid (3mol / L), acetone, absolute ethanol and deionized water for 5 minutes respectively.

[0056] The second step: CVD growth of graphene

[0057] First, put nickel foam into a tube furnace and heat it to 1035°C at 10°C / min under an atmosphere of argon (300sccm); secondly, heat-preserve and anneal foamed nickel at a temperature of 1035°C and a mixed atmosphere of argon (50sccm) and hydrogen (50sccm) 15 minutes; after annealing, the gas atmosphere in the tube furnace remains unchanged, and the temperature drops to 1000°C; after reaching the growth temperature of 1000°C, methane is introduced as a carbon source, and the mixed gas in the tube furnace becomes 20sccm hydrogen, 50sccm Argon and 100 sccm methane, incubation for 20 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com