Evaporation chamber lining device, evaporation system, and evaporation device

An evaporation device and lining technology, applied in the field of semiconductor technology, can solve the problems of high cost of crystal oscillator device, long heating time of materials, material leakage, etc., and achieve the effect of reducing the cost of crystal oscillator device loss, improving product production capacity, and reducing installation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

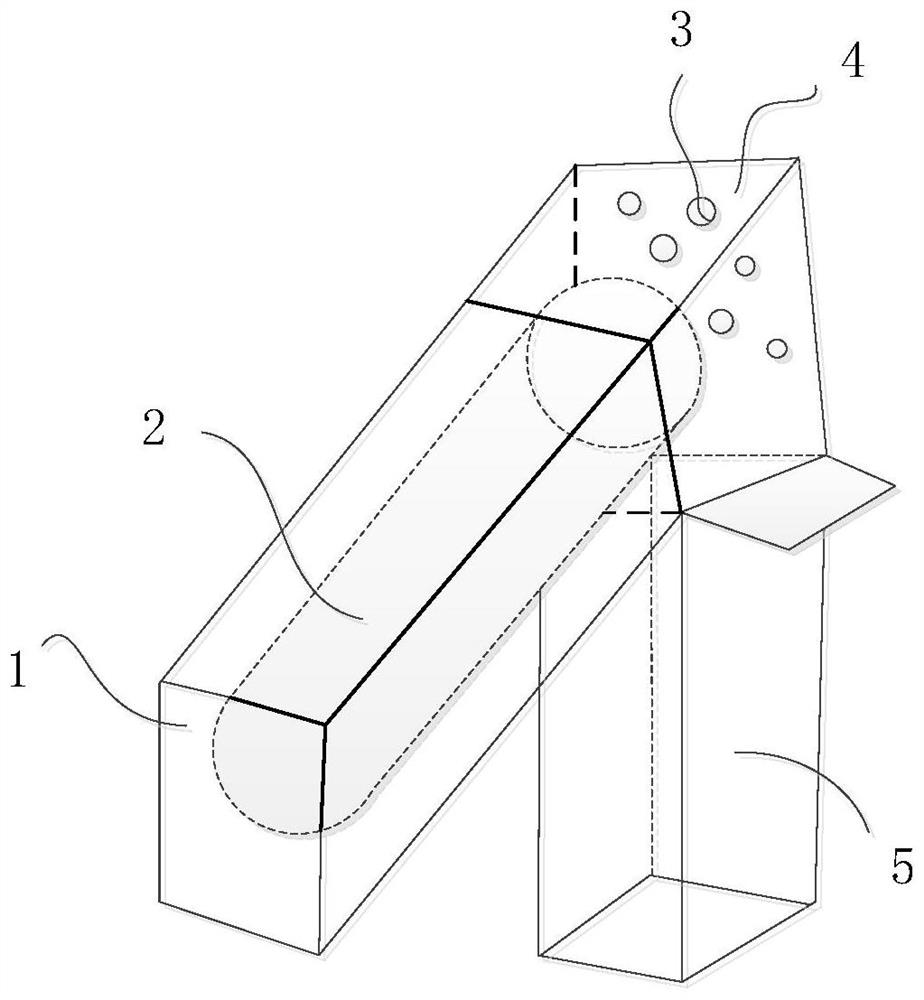

[0046] This embodiment provides an evaporation chamber lining device, such as figure 1 As shown, it includes a chamber assembly 1, and the chamber assembly 1 includes, a first housing, which has a first open end and a second open end oppositely arranged, and the first open end is externally connected to an evaporating device 6, and the A steam channel 2 suitable for steam circulation is formed in the first housing; a second housing is communicated with the second open end, and a material retention area 4 for retaining steam from the steam channel 2 is formed in the second housing .

[0047] Further, a recovery device 5 is also included, which communicates with the bottom of the second casing, so that the materials in the material storage area 4 can be recovered into the recovery device 5 without worrying that the materials will pollute the overall evaporation environment. Preferably, the recovery device 5 is in detachable communication with the second housing. The present in...

Embodiment 2

[0051] This embodiment provides an evaporation chamber lining device. On the basis of the above-mentioned embodiment 1, it also includes a heating assembly, which is arranged on the steam channel 2 to heat the material remaining on the inner wall of the steam channel 2. And make it into the material retention area. This embodiment does not specifically limit the specific structure of the heating assembly. Optionally, the heating assembly is an annular heating assembly, and the annular heating assembly is wound on the first casing to Steam channel 2 is heated. Optionally, the annular heating component may be a heating wire or a heating rod. Optionally, the shape of the heating wire may be wavy, helical or a combination of wavy and helical.

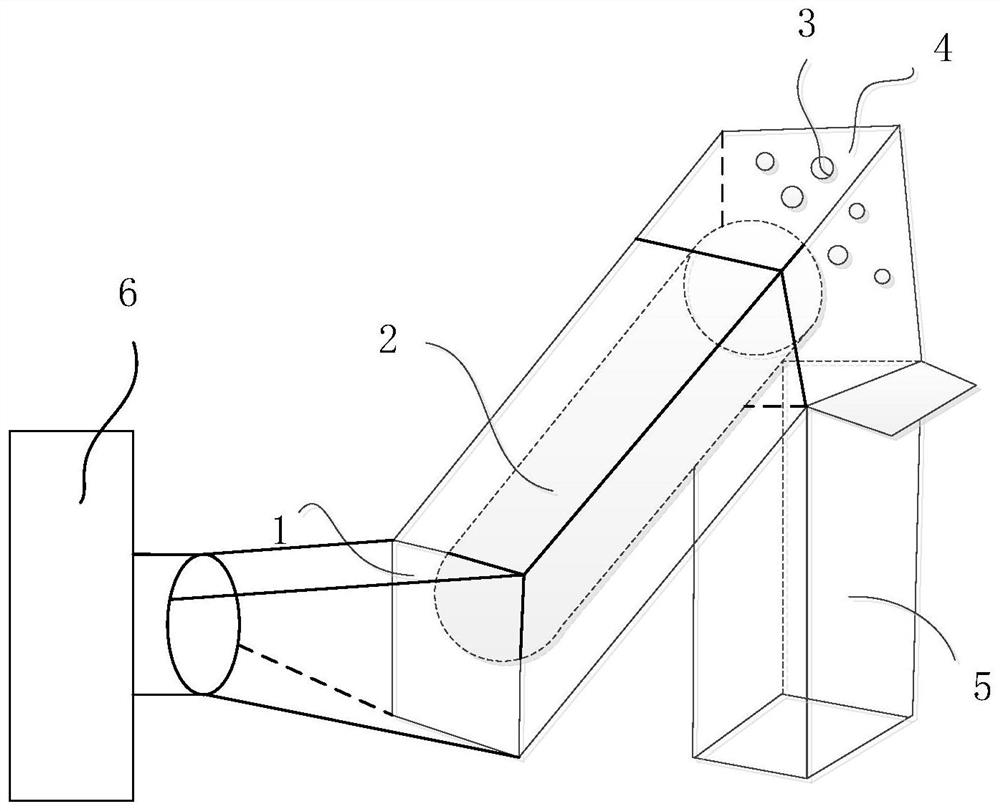

[0052] Further, such as figure 2 As shown, the evaporation device 6 is set to heat up the organic material for evaporation. The present invention does not specifically limit the structure of the evaporation device 6, as long as the orga...

Embodiment 3

[0054] This embodiment provides an evaporation chamber lining device. On the basis of the above-mentioned embodiments 1 and 2, the shape of the first casing is a cuboid; the shape of the second casing is a cuboid or a cube; The shape of the recovery device 5 is a cuboid. Optionally, the first housing, the second housing and the recovery device 5 may also be circular or cube structures. Optionally, the materials of the first casing, the second casing and the recovery device 5 are all stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com