Simple mechanism for testing cycle indexes of springs of windscreen wipers

A technology of cycle times and simple mechanism is applied in the field of testing tools for tensile spring performance and simple mechanism for testing the cycle times of automobile wiper springs. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

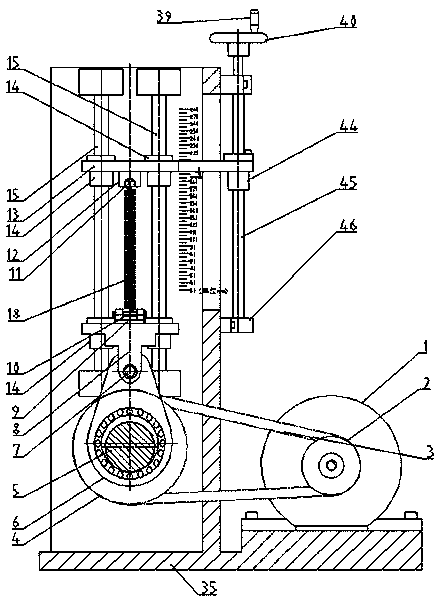

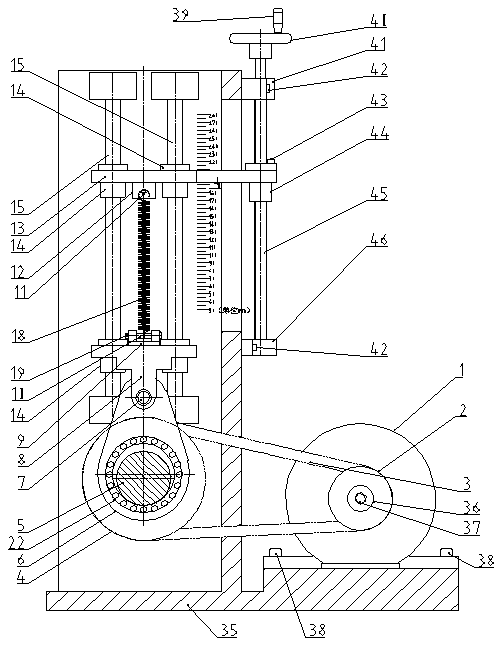

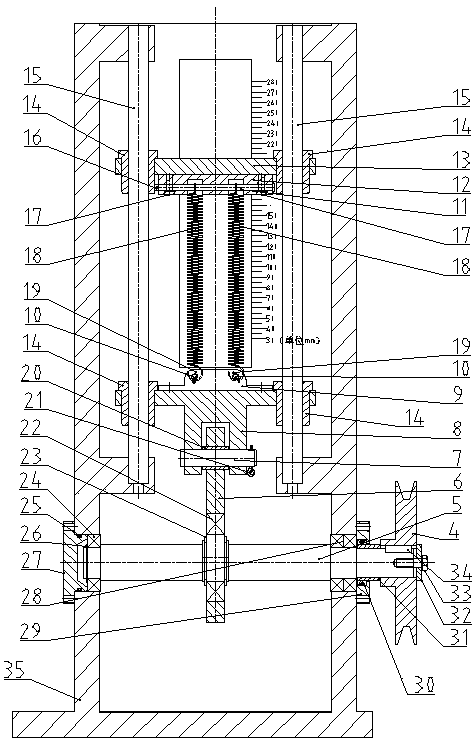

[0018] Such as figure 1 As shown, the present invention comprises main frame 35, electric motor 1, large pulley 4, eccentric shaft 5, connecting rod 6, lower slider 8, lower mold 9, spring 18, upper mold 12, upper slider 13, guide column 15 , screw mandrel 45, handle 39, hand wheel 40, motor 1, large pulley 4, eccentric shaft 5 are housed on main frame 35, small pulley 2 is housed on motor 1, and small pulley 2 drives large pulley by belt 3 4. The large pulley 4 drives the eccentric shaft 5 through the key 34, the eccentric shaft 5 makes a circular motion, the eccentric body of the eccentric shaft 5 drives the connecting rod 6 to make a reciprocating motion, and the connecting rod 6 drives the lower slider 8 through the connecting rod pin 7, The lower mold 9 and the lower hanging pin 10 mounted on the lower slider 8 reciprocate together with the slider 8, the lower end of the spring 18 is hung on the lower hanging pin 10, the upper end of the spring 18 is hung on the upper han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com