A high-tight gas-tight rapid pressure regulation system and method

A pressure-regulating system and high-sealing technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as high price, toxicity and radioactive hazards, improve technical capabilities, maintain stability, and reduce expensive The effect of gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

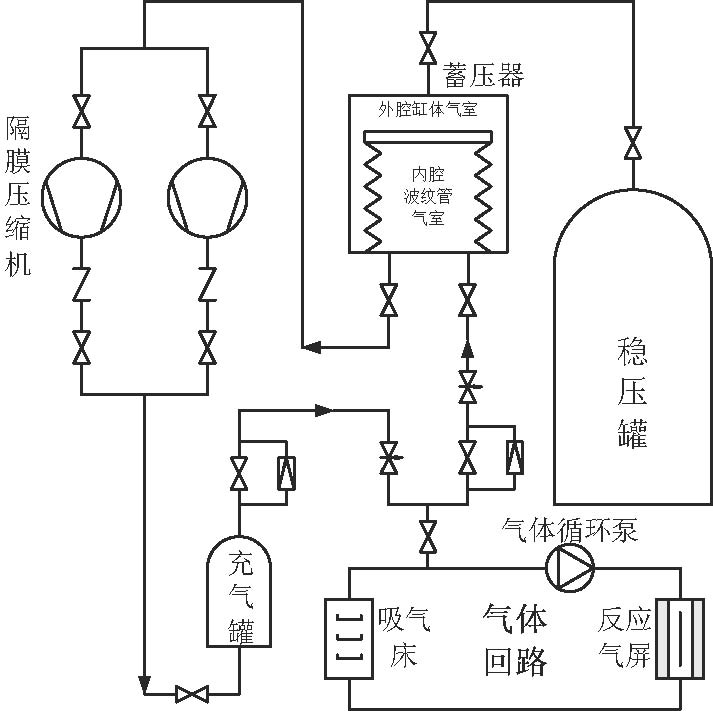

[0032] A process flow diagram of a gas high-tightness rapid pressure regulation system, as attached figure 1 shown. The rapid pressure regulating system of the present invention is mainly composed of a gas circuit, a pressure accumulator, a pressure-stabilizing tank, two diaphragm compressors, an inflatable tank, valves, pipelines and instruments. The reaction gas screen in the reactor is connected with equipment such as the getter bed outside the reactor and the gas circulation pump through the inlet and outlet pipelines to form a gas circuit with high sealing and forced circulation. The pressure regulating branch of the gas circuit is respectively connected to the inlet of the pressure accumulator and the outlet of the gas charging tank, the outlet of the pressure accumulator is connected to the inlet of the metal diaphragm compressor, and the outlet of the metal diaphragm compressor is connected to the inlet of the gas charging tank.

[0033] For the fuel element power tra...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the present invention provides a volume compensation method through a flexible bellows to ensure the inlet pressure requirements of the diaphragm compressor when venting or pumping air from the accumulator, and also proposes a The device and method for reducing the amount of gas remaining in the pressure accumulator, the specific setting method is as follows:

[0038] In order to make all the expensive process gas in the pressure accumulator enter the metal diaphragm compressor for compression and ensure that the inlet pressure of the metal diaphragm compressor is close to normal pressure or a certain set pressure, the pressure accumulator of the present invention is designed to be variable Volume compensation form. The pressure accumulator is composed of an outer cylinder body air chamber and an inner bellows air chamber. The air inlet of the inner bellows air chamber of the pressure accumulator communica...

Embodiment 3

[0042] The difference between this embodiment and Embodiment 2 or Embodiment 3 is that the sealing setting and material selection are optimized to ensure the ultra-high sealing and safety of the entire pressurization and pressure regulation system. The specific setting method is as follows:

[0043] The pressure accumulator of the present invention uses a fully sealed metal bellows diaphragm to divide the inside of the pressure accumulator into inner and outer sides, and the volume change chamber of the pressure accumulator is completely contained by a sealed welded bellows to avoid the volume change process of the inner cavity Seal leaks in. At the same time, the pressure accumulator also has an outer cylinder block, which is connected with the surge tank to form a second containment boundary. The inside of the surge tank is fully welded and sealed. Even if the bellows breaks, radioactive or dangerous gases will only leak into the pressure accumulator. The space of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com