Vacuum evaporation crucible

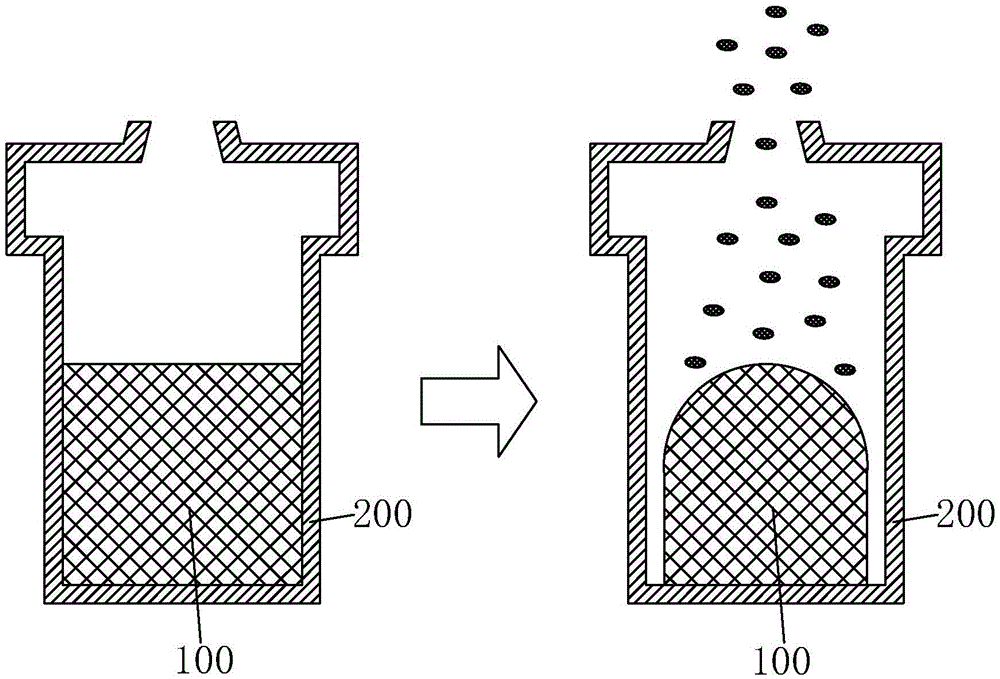

A crucible and evaporation technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of material deterioration, gaseous molecules running away, sublimation rate instability, etc., to increase the contact area , The evaporation rate is stable, and the effect of improving the evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

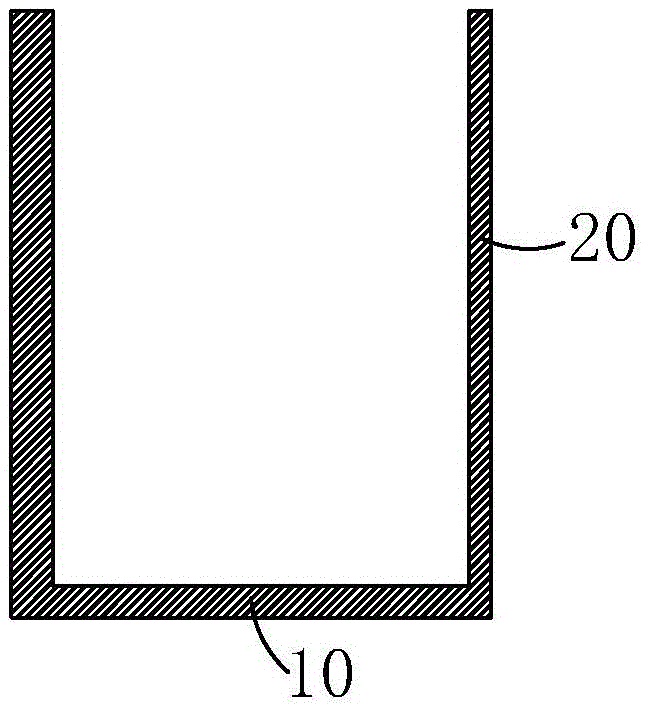

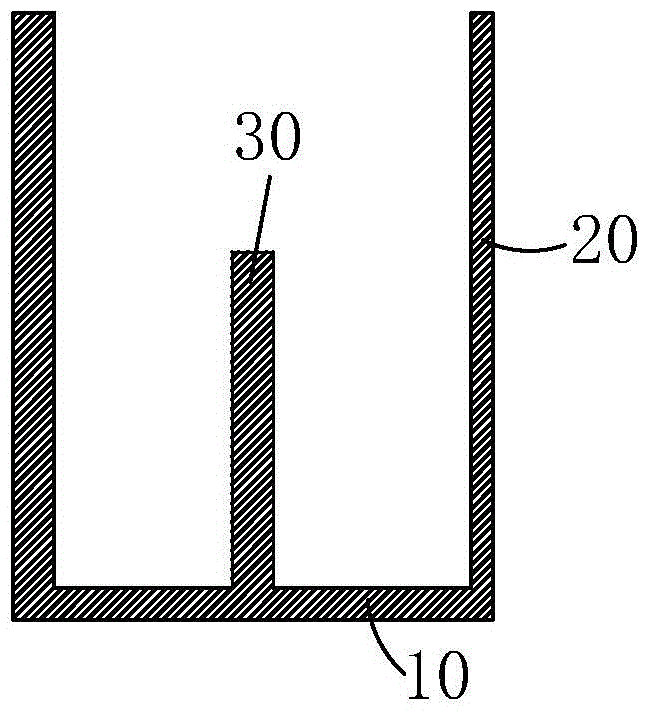

[0029] see Figure 2-7 , which is the first embodiment of the evaporation crucible of the present invention, the evaporation crucible includes a crucible bottom 10 and a side wall 20 connected to the crucible bottom 10, the side wall 20 and the crucible bottom 10 enclose a A hollow chamber, the hollow chamber includes several blind holes 23 that are connected and extend in the same direction as the side wall 20. The inner surface of the side wall 20 includes several recessed The first arcuate surfaces 21 , the plurality of first arcuate surfaces 21 are respectively part of the hole walls of the plurality of blind holes 23 .

[0030] Specifically, the crucible bottom 10 and the side wall 20 are made of metal, such as titanium or aluminum.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com