High-damage threshold laser lens and manufacturing method thereof

A technology with high damage threshold and manufacturing method, applied in optics, mirrors, optical components, etc., can solve the problems of reduced damage threshold of zirconia thin film, limited application of zirconia materials, insufficient auxiliary energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

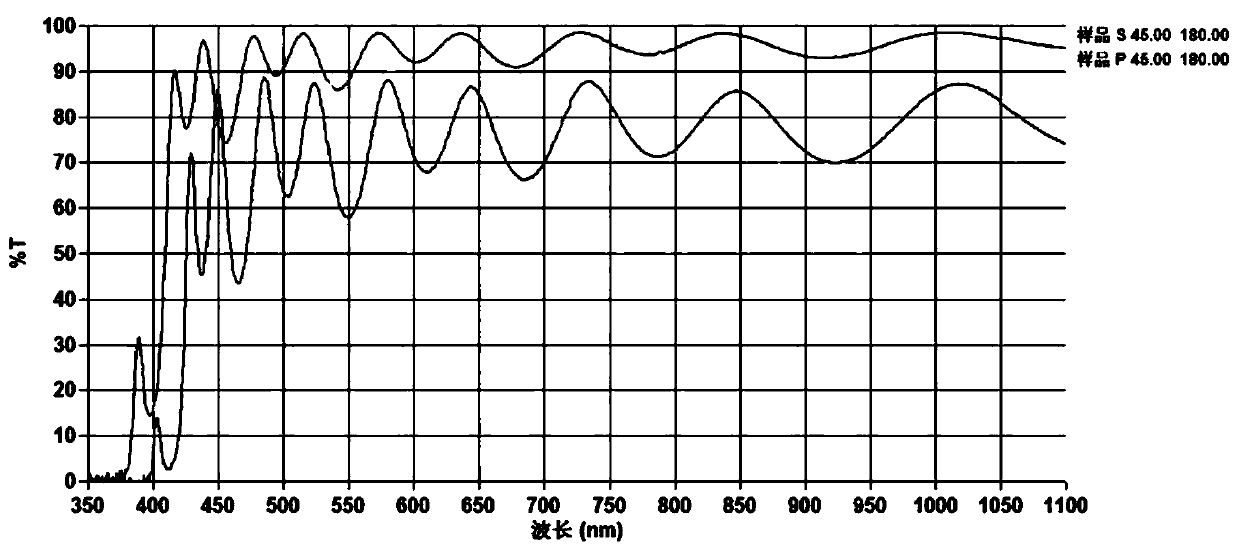

[0047] Example 1 is a laser lens made by directly evaporating zirconia material, and the measured average damage threshold of the laser lens is 5.6 J / cm 2 10ns@355nm.

[0048] 1. Directly evaporate zirconia material to make reflective film:

[0049] Use TFCALC35 software to design 355nm reflective film, center wavelength 393nm, incident angle 45°, incident medium air, base material JGS1, exit medium JGS1, design layers 30 layers, including 15 layers of zirconium dioxide, each layer thickness 48.77nm, cumulative thickness 731.6nm, 15 layers of silicon dioxide, the thickness of each layer is 66.96nm, the cumulative thickness is 1004.35nm, and the total thickness of the film is 1735.96nm. Among them, the refractive index of zirconia at 355nm is 2.038, the refractive index of silicon dioxide at 355nm is 1.467, and the reflectivity of the designed film layer at 355nm is 99.8%. The glass substrate adopts domestic JGS1 grade fused silica, the size is D25.4*5mm, the surface shape r...

Embodiment 2

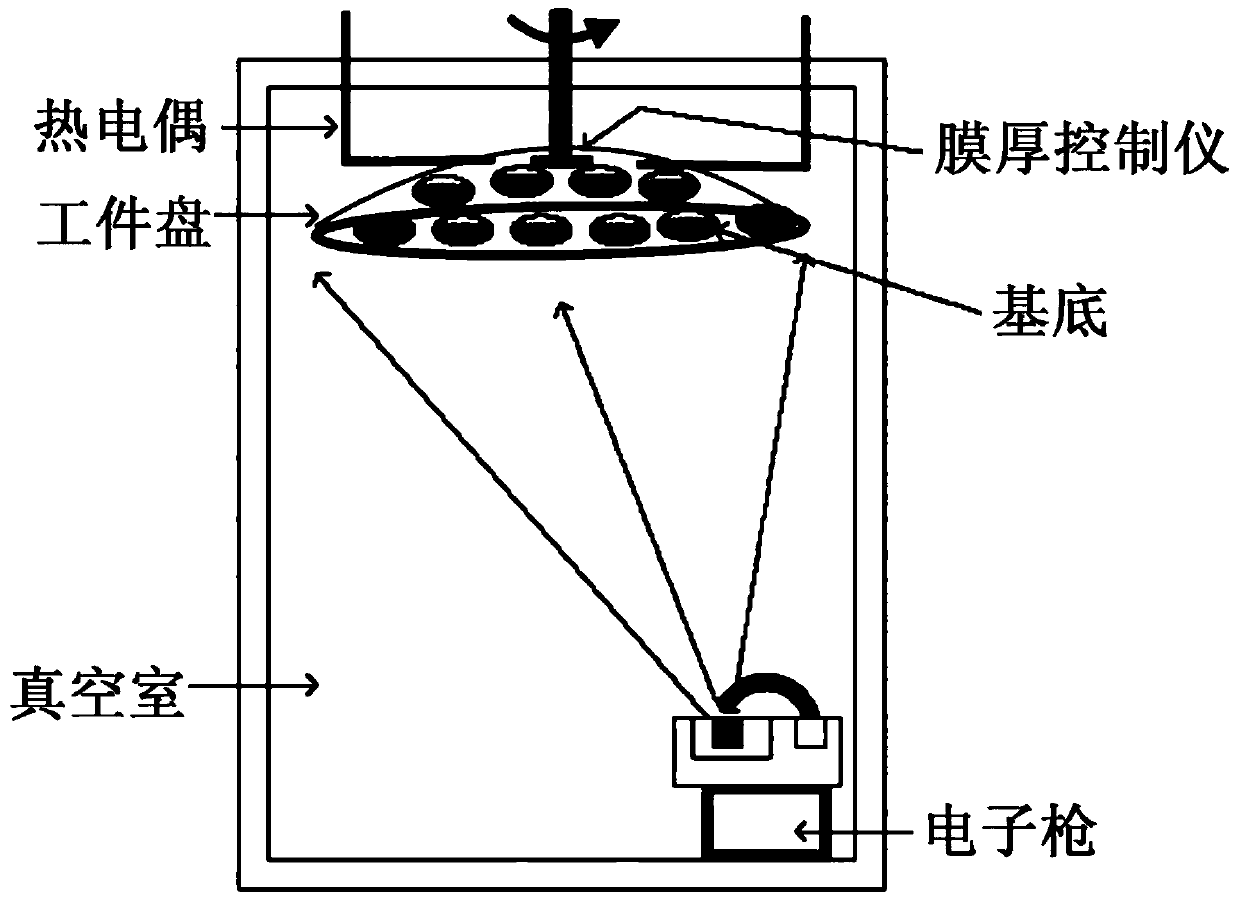

[0053] Such as figure 1 with figure 2 Shown, a kind of manufacturing method of high damage threshold laser lens, the method step comprises:

[0054] Step 1: Substrate preparation: Wipe the surface of the fused silica, put the wiped lens into the sheet holder, and put the sheet holder on the workpiece tray of the coating machine; the glass substrate is made of domestic JGS1 grade fused silica, the size is φ25.4* 5mm, the surface shape reaches 1 / 4λ@633nm, and the surface quality is 10-5. Use a solution of 7:3 volume ratio of 100-grade non-woven fabric to wipe the surface, and put the wiped lens into the lens holder. The sheet holder is placed on the workpiece tray of the coating machine.

[0055] Step 2: Preparation before plating: such as figure 1 As shown, the zirconium tin alloy is placed in the acupoint crucible, the background of the vacuum chamber is evacuated, and the zirconium tin alloy is pre-melted several times in batches; 1000g of the zirconium tin alloy with a...

Embodiment 3

[0064] Such as figure 1 Shown, a kind of manufacturing method of high damage threshold laser lens, the method step comprises:

[0065] Step 1: Substrate preparation: Wipe the surface of the fused silica, put the wiped lens into the sheet holder, and put the sheet holder on the workpiece tray of the coating machine; the glass substrate is made of domestic JGS1 grade fused silica, the size is φ25.4* 5mm, the surface shape reaches 1 / 4λ@633nm, and the surface quality is 10-5. Use a 4:1 volume ratio solution of 100-grade non-woven fabric to wipe the surface, and put the wiped lens into the lens holder. The sheet holder is placed on the workpiece tray of the coating machine.

[0066] Step 2: Preparation before plating: such as figure 1 As shown, the zirconium tin alloy is placed in the acupoint crucible, the background of the vacuum chamber is evacuated, and the zirconium tin alloy is pre-melted several times in batches; 1000g of the zirconium tin alloy with a tin content of 0.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com