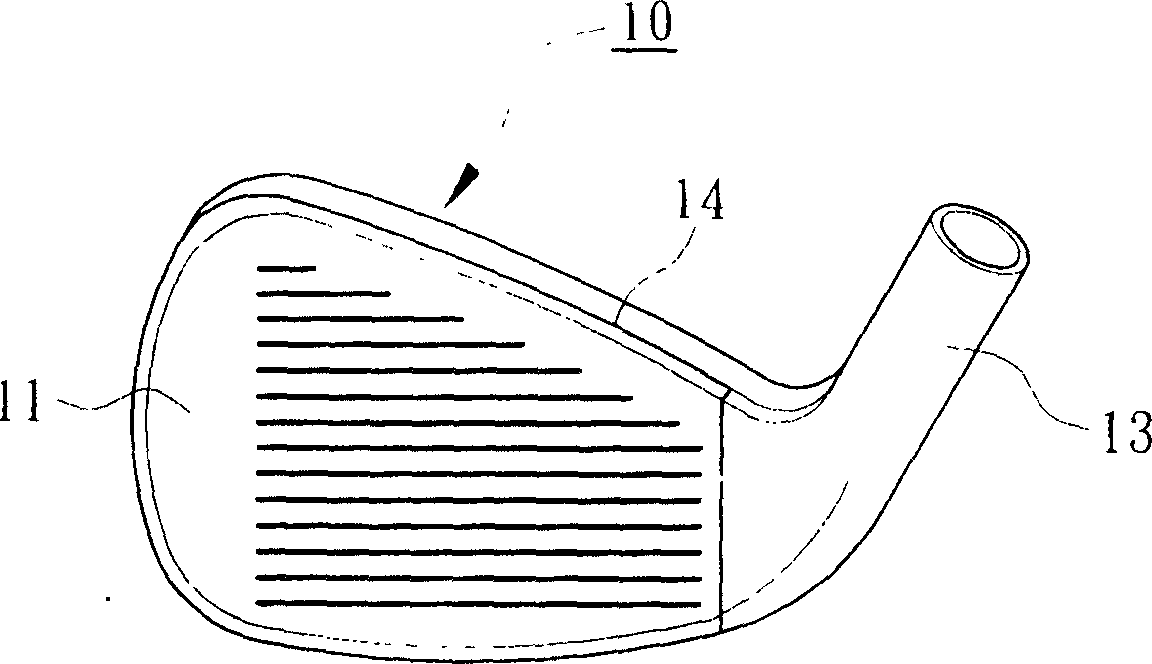

Head of golf club and manufacturing method

A technology for golf club heads and manufacturing methods, which can be applied to golf balls, golf clubs, rackets, etc., and can solve the problems of the overall center of gravity, the impact of long-distance hitting ability and elastic deformation ability, and increase the cost of mold opening, so as to increase the design The effect of margin, improving elastic deformation capacity, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

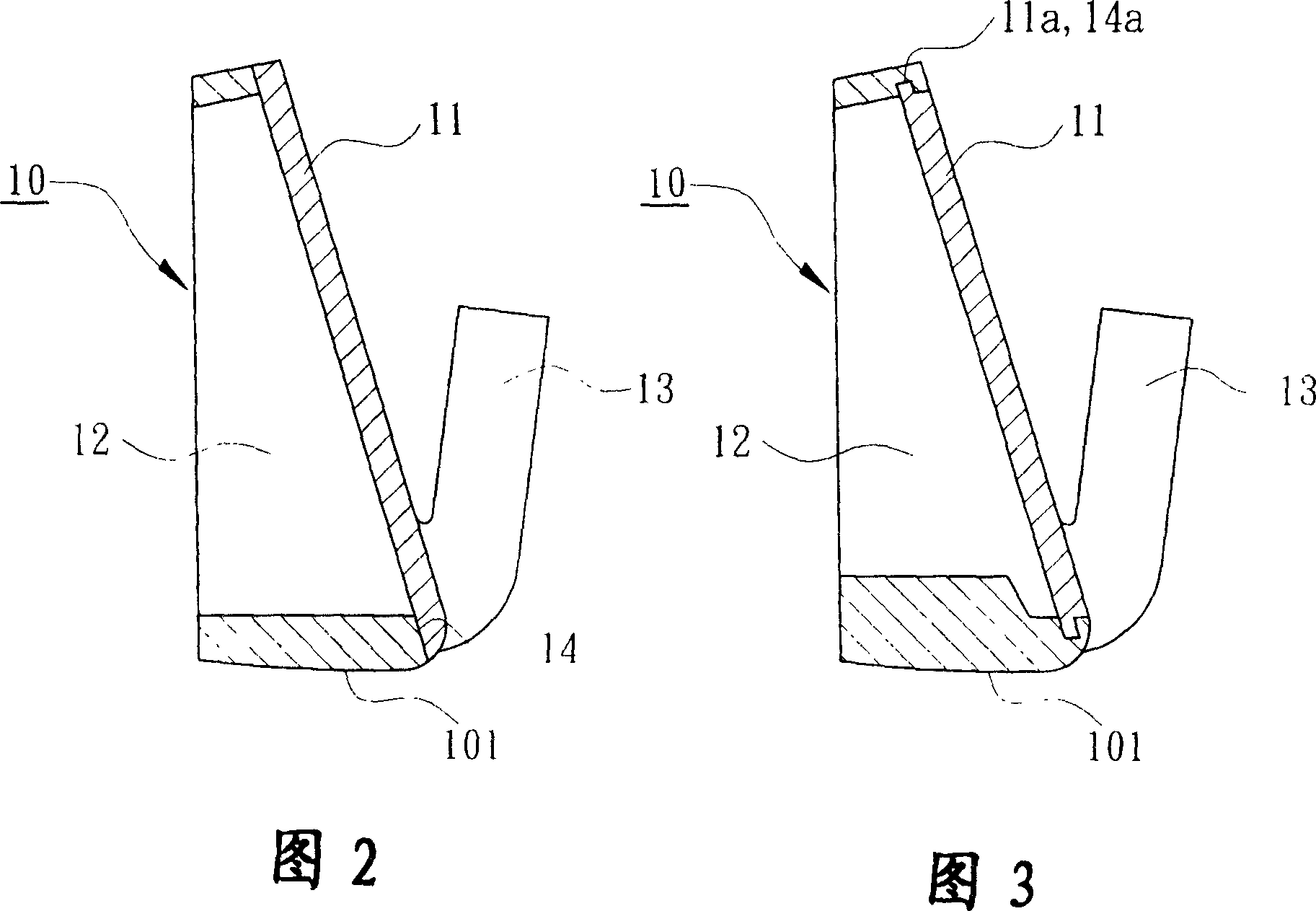

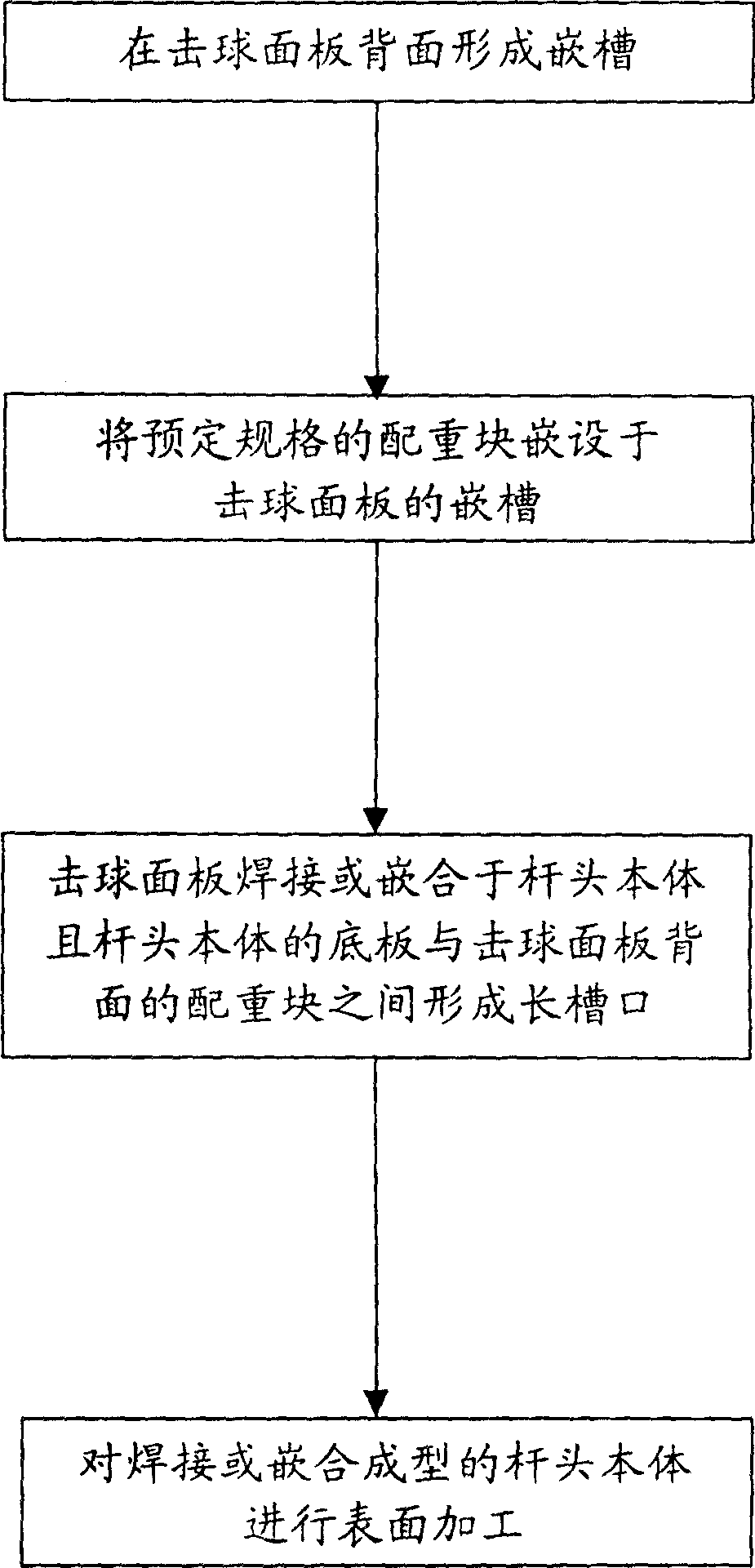

[0056] In order to make the above-mentioned technical solutions, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and detailed descriptions are as follows:

[0057] Figure 4 It is a flow block diagram showing the manufacturing method of the golf club head of the present invention; FIG. 5 is an exploded perspective view showing the golf club head of the first embodiment of the present invention; Figure 6 To reveal the combined rear view of the golf club head according to the first embodiment of the present invention; FIG. 7 is a combined sectional view showing the golf club head according to the first embodiment of the present invention; FIG. 8 is a combined sectional view showing the golf club head according to the second embodiment of the present invention combined sectional view; Figure 9 An assembled sectional view of a golf club...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com