Sintering device, calcination machine double-ramp type move plate slide track sealing device

A slope type, roasting machine technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of reduced sealing effect, loss of elastic effect, poor sealing effect, etc., to achieve small contact force, prevent deformation, and seal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

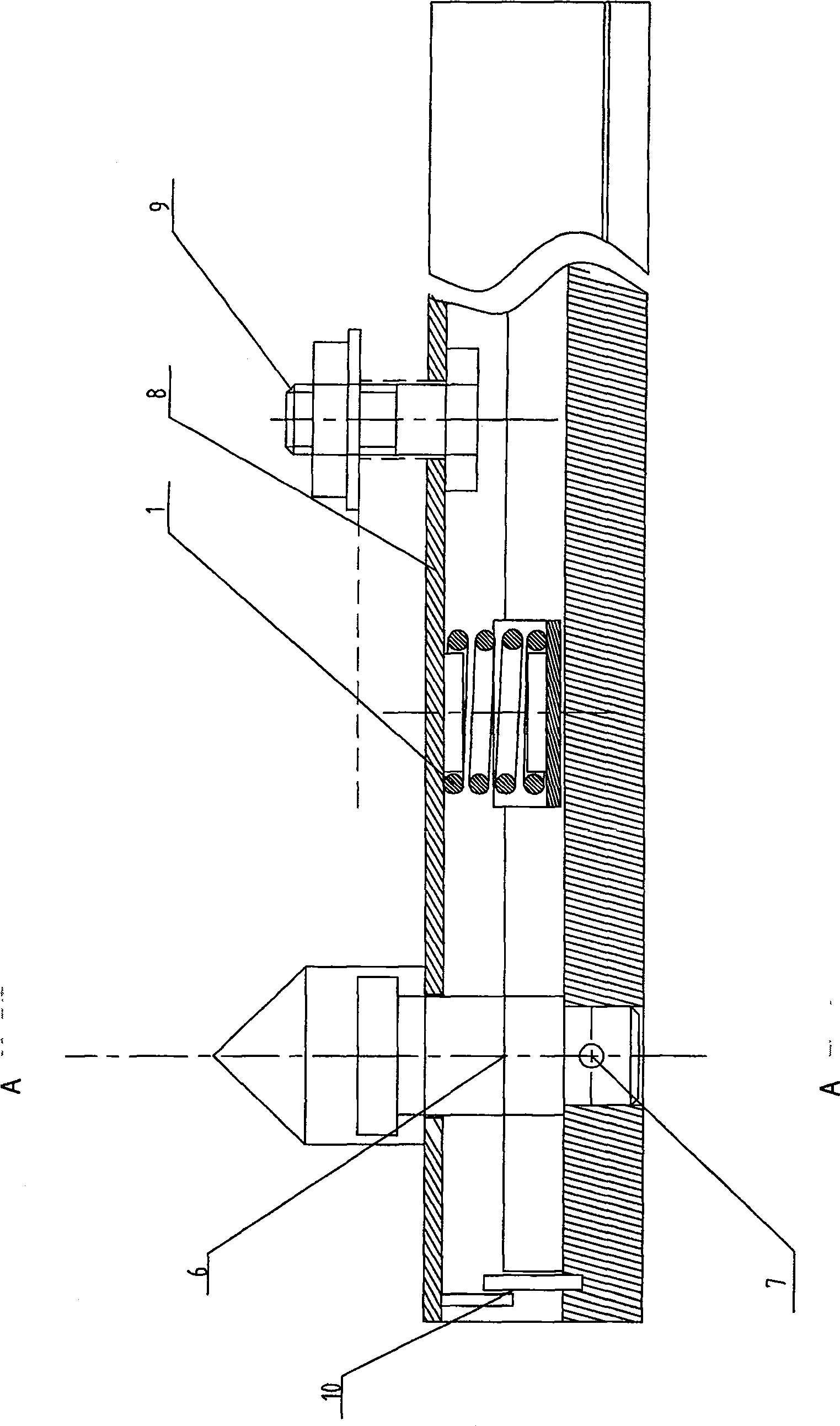

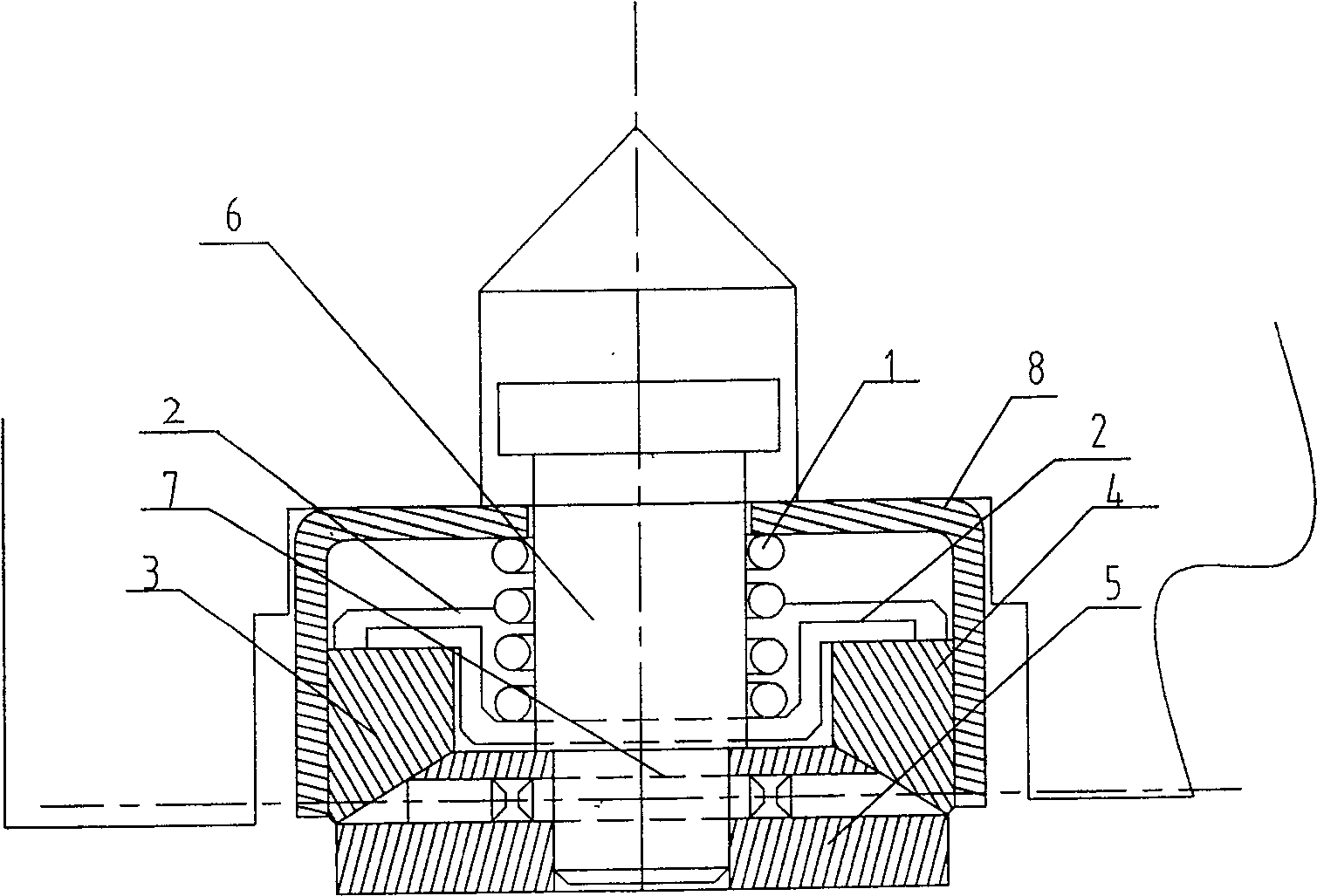

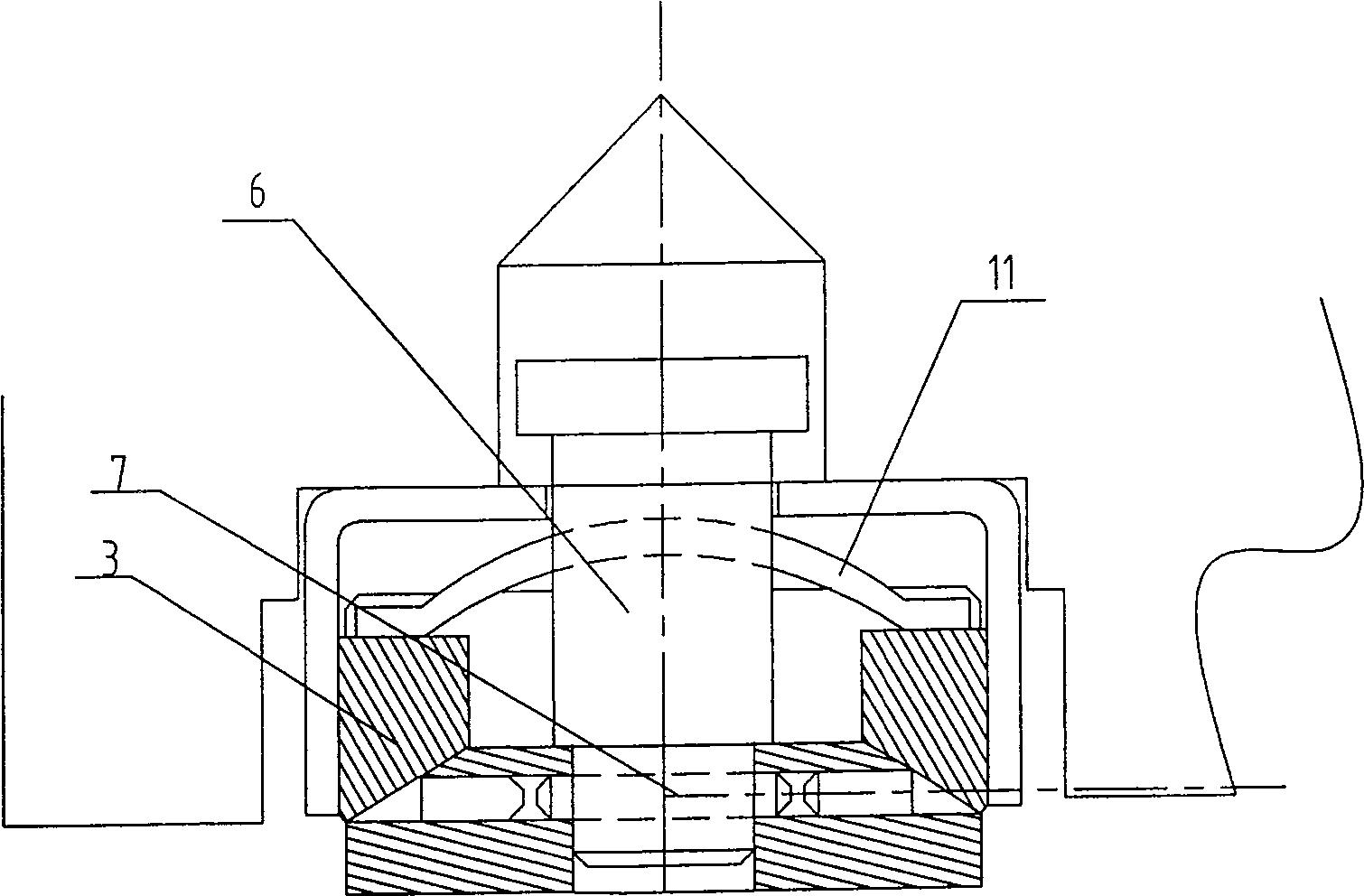

[0027] Such as figure 1 , figure 2 As shown, the sintering machine and roasting machine double-slope type travel plate slideway sealing device of the present invention is characterized in that: the device consists of a travel plate groove 8, an elastic component arranged in the travel plate groove 8, and the elastic component The crimped sealing blocks 3, 4, the double-slope type swimming plate 5 crimped with the sealing blocks 3, 4, the pin shaft 6, and the pin 7 are composed. The upper end of the elastic part is pressed on the inner surface of the swimming plate groove 8, and the lower end is pressed On the sealing blocks 3 and 4, the sealing blocks 3 and 4 are pressed on the double-slope swimming plate 5, and are close to the inner walls on both sides of the swimming plate groove 8, and the pin shaft 6 is passed through the upper side hole of the swimming plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com