Flange structure

A technology of flange components and flanges, applied in the direction of passing components, engine components, lubricating parts, etc., can solve problems such as high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

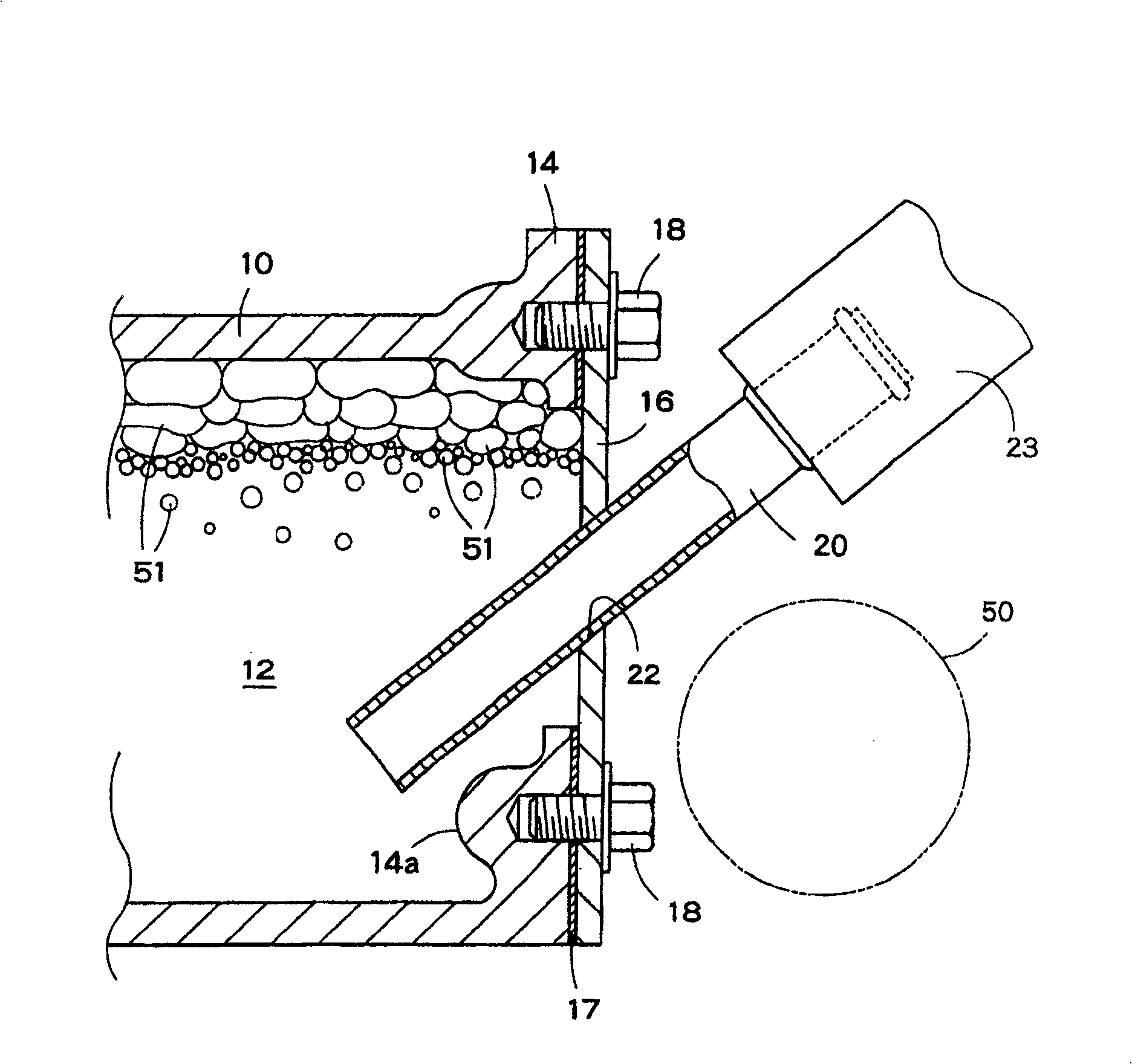

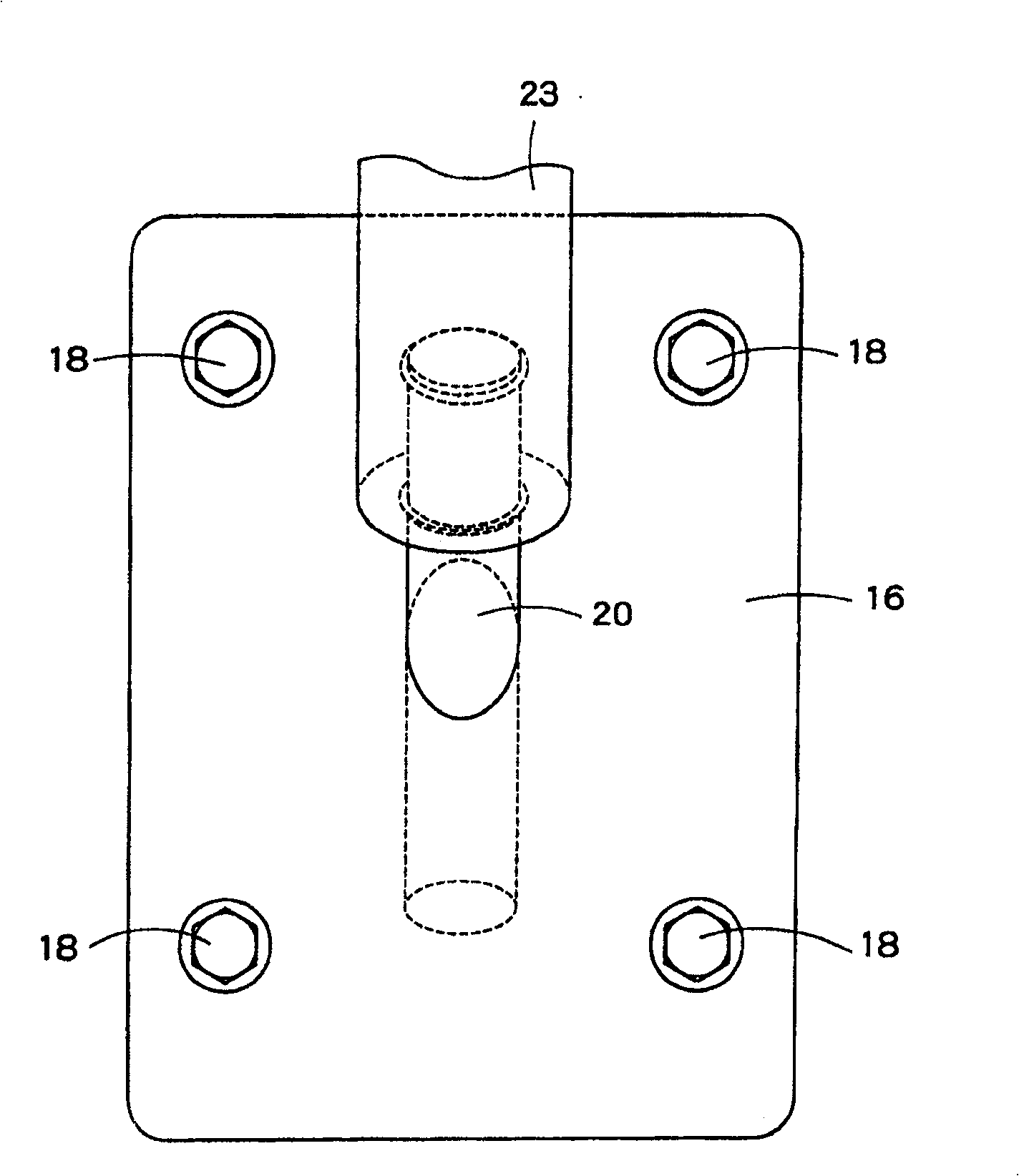

[0033] figure 1 There is shown a flange member of a first embodiment of the present invention, which is combined with a main part 10 of a heater core for heating using cooling water for cooling a motor vehicle engine, wherein the heater core is a fluid device. figure 2 yes figure 1 Front view of the flange member shown. The main part 10 of the heater core has fluid passages 12 through which cooling water flows. A flange 14 having a joint surface is formed at the free end of the main part 10 . The flange member includes a plate part 16 . and Figure 5 Unlike the conventional connector flange 2 shown provided with the boss 4, the plate member 16 is a planar member and has a uniform thickness. The plate member 16 is a metal plate whose shape corresponds to that of the flange 14 of the main part 10 . A gasket 17 is held between the joint surface of the flange 14 and the joint surface of the plate member 16 . Such as figure 2 As shown, the plate member 16 is fastened to ...

no. 2 approach

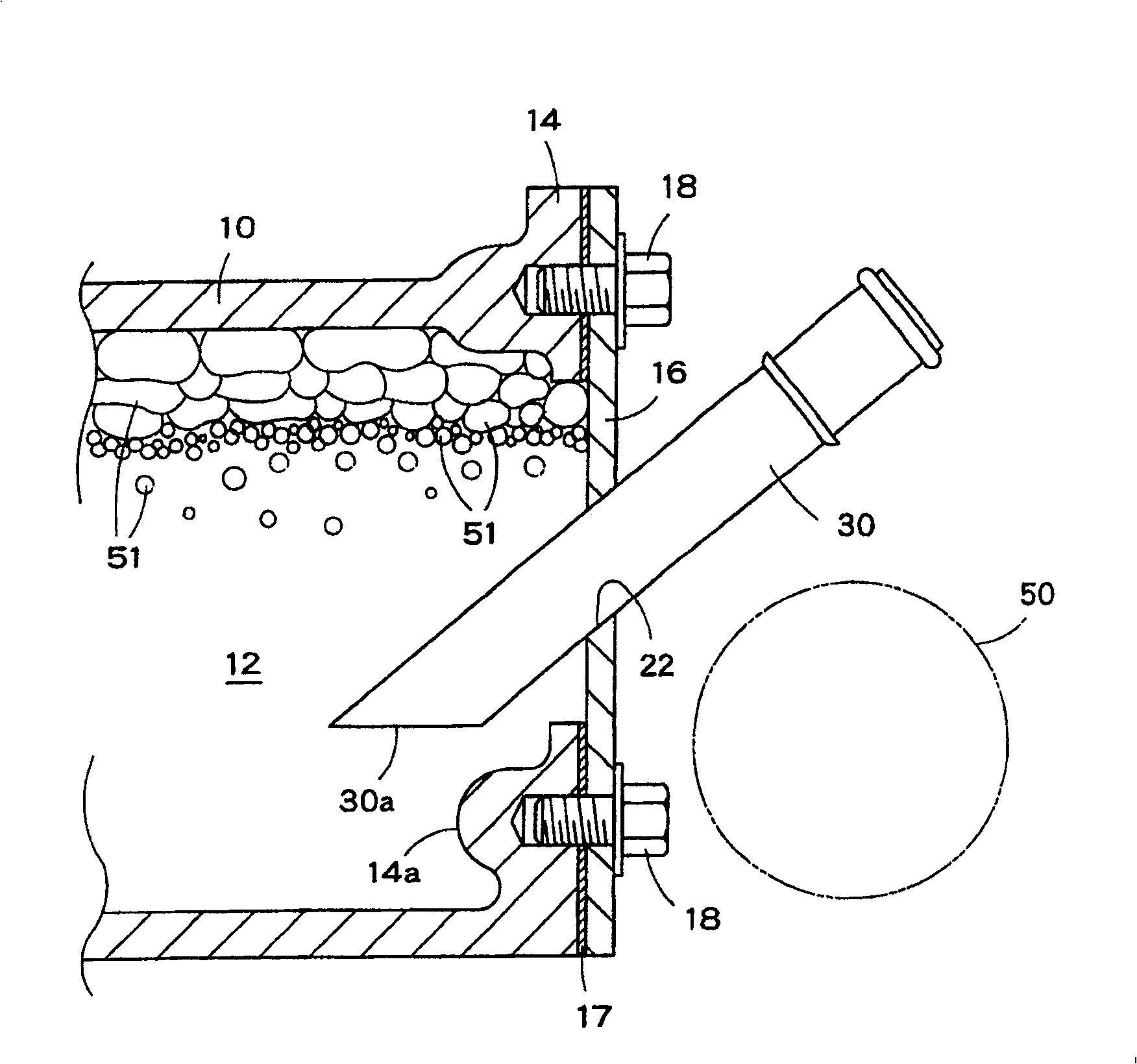

[0041] Below, refer to image 3 A flange member according to a second embodiment of the present invention will be described. The flange member in the second embodiment is similar to the flange member in the first embodiment, so the parts of the second embodiment that are the same as or corresponding to the parts of the first embodiment are given the same reference numerals and omitted. illustrate.

[0042] The flange member in the second embodiment differs from the flange member in the first embodiment only in the shape of the inner end portion of the connecting pipe 30 included therein.

[0043] Such as image 3 As shown, the connecting pipe 30 has an oblique inner end 30 a contained in a plane inclined relative to the axis of the connecting pipe 30 . The slanted inner end 30a enhances the separation of gas from liquid. The connecting pipe 30 is inserted into the main part 10 through the inclined opening 22 formed in the plate member 16 . The connecting pipe 30 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com