Split electric steam iron

An electric iron and split-type technology, applied in the field of appliances for ironing clothes, can solve the problems of large occupied space, high cost, inconvenient use and installation, etc., and achieve the effects of avoiding safety accidents, timely liquid level signals, and scientific design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

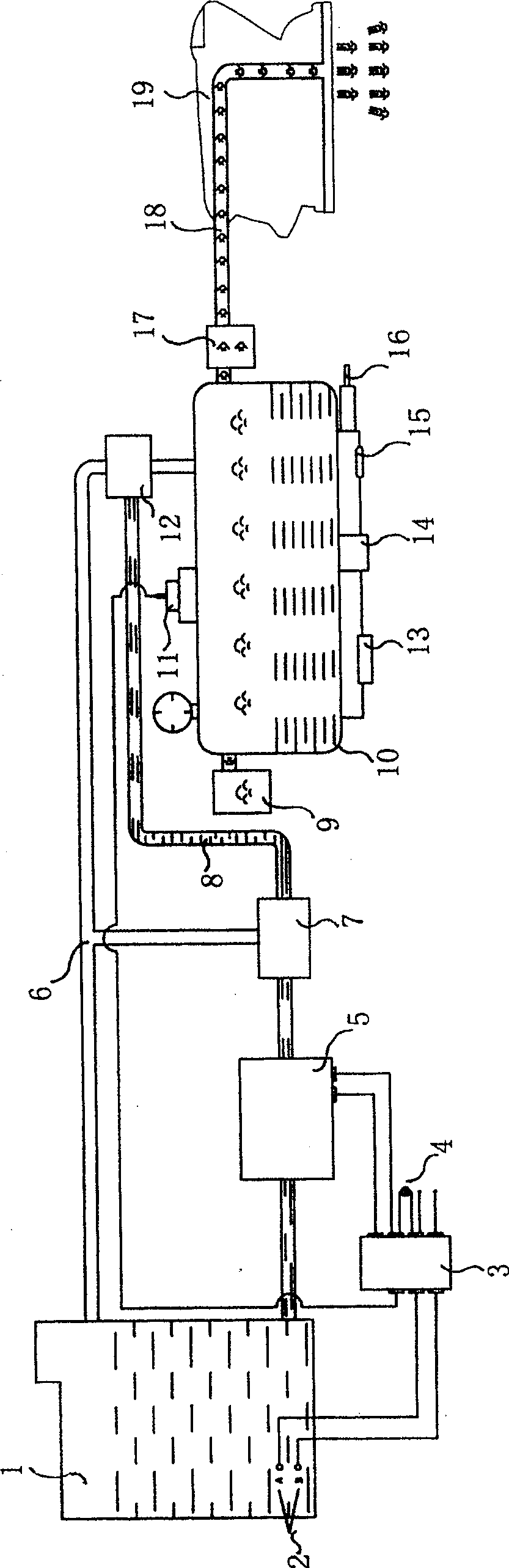

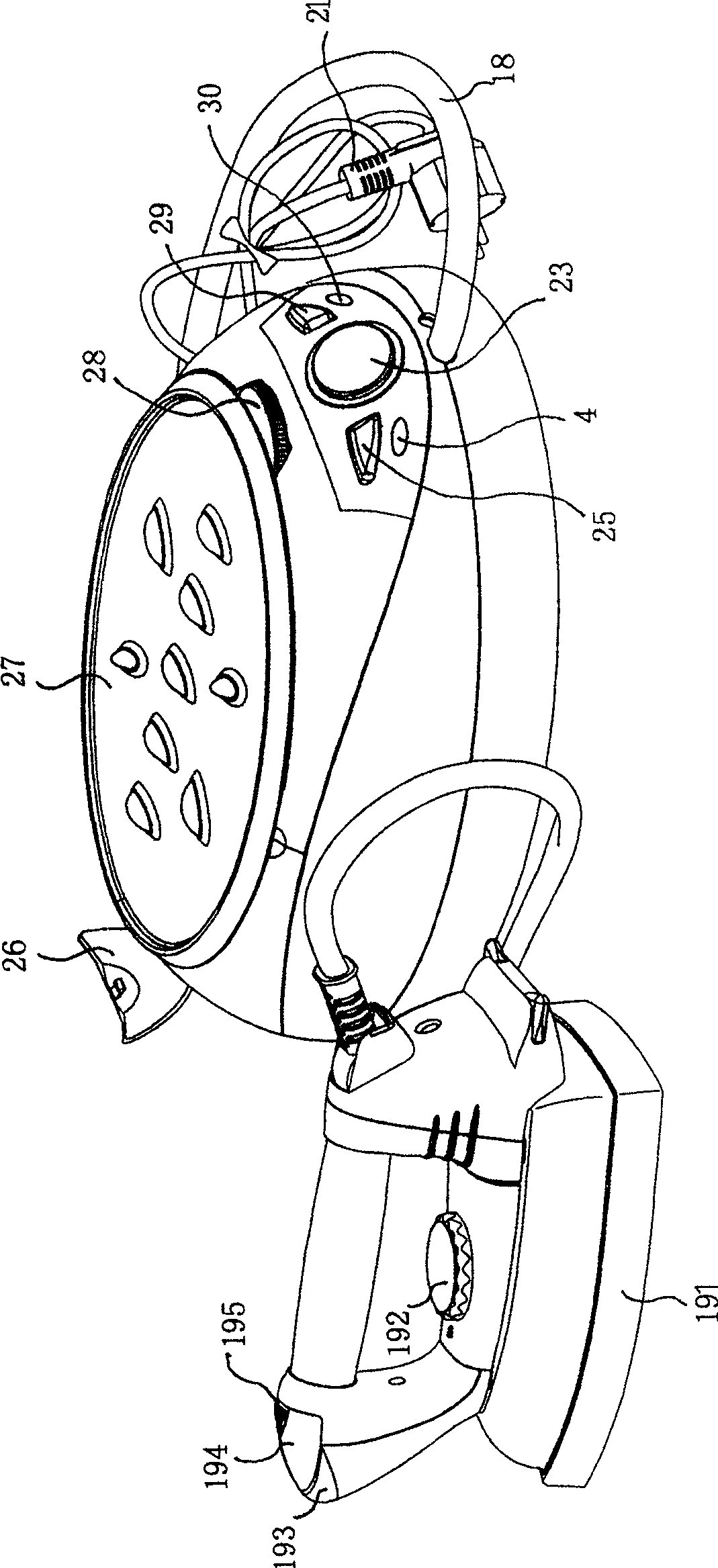

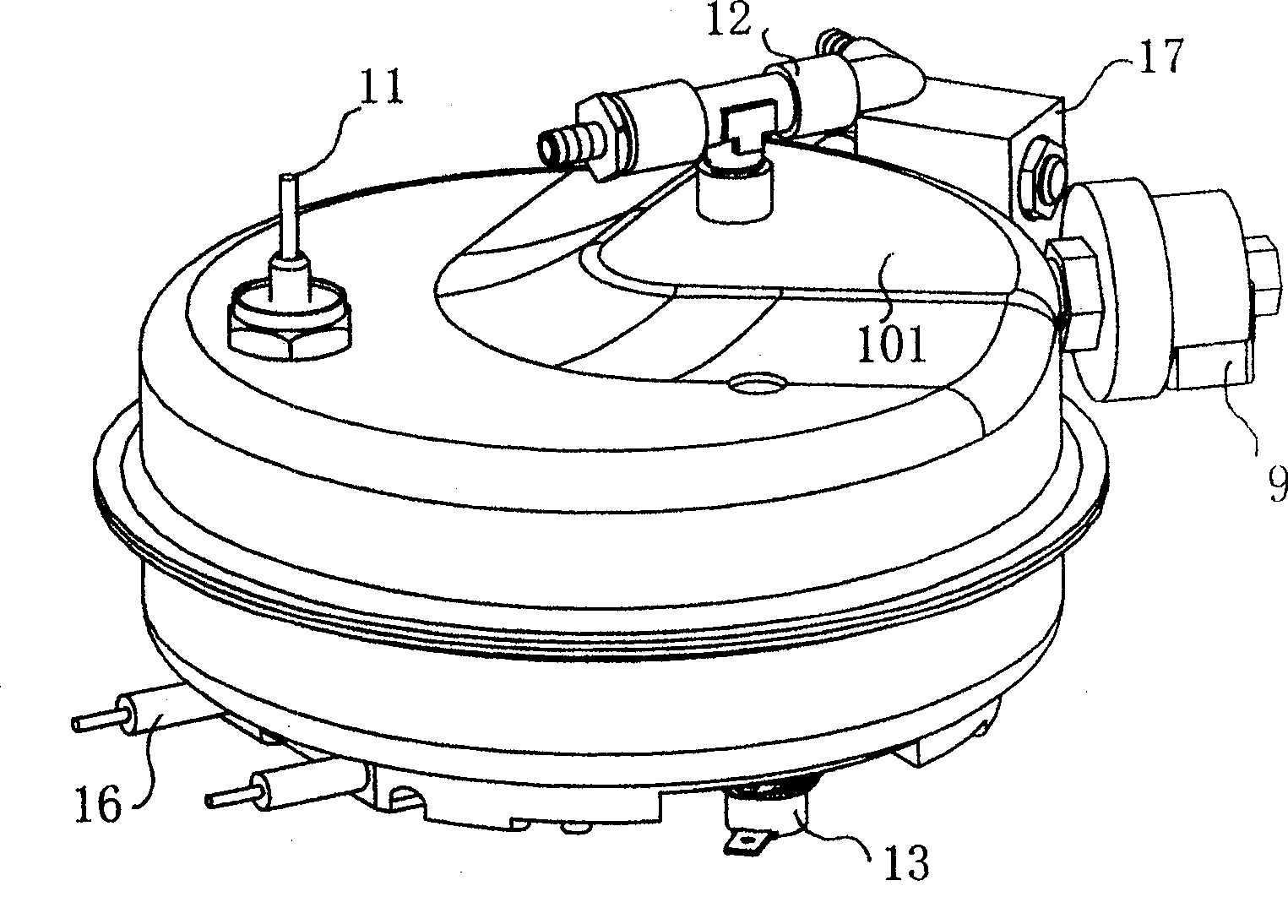

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings. A split type steam electric iron of the present invention comprises a steam electric iron base with a boiler steam generator, an electric iron connected with a steam pipe, and a power supply system; it is characterized in that it has a signal transmitted by a liquid level sensor 11, A water supply system that automatically supplies water to the boiler 10 controlled by the single-chip microcomputer 3 . An external electric heating device controlled by a pressure switch 9 to heat the boiler 10 . The power supply system on the base of the embodiment of the present invention includes a power cord plug 21 ( figure 2 ), steam delivery pipe and cable 18 (the two are put together), steam pressure indicator 23, water tank water shortage indicator light 4, iron power switch 25, steam indicator light 30. Boiler power switch 29. The water supply system is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com