Railroad locomotive running simulation test bed

A technology for vehicle operation and railway locomotives, applied in the direction of railway vehicle testing, etc., can solve the problems of complex structure, inability to carry out, and inconvenient dynamic parameter detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

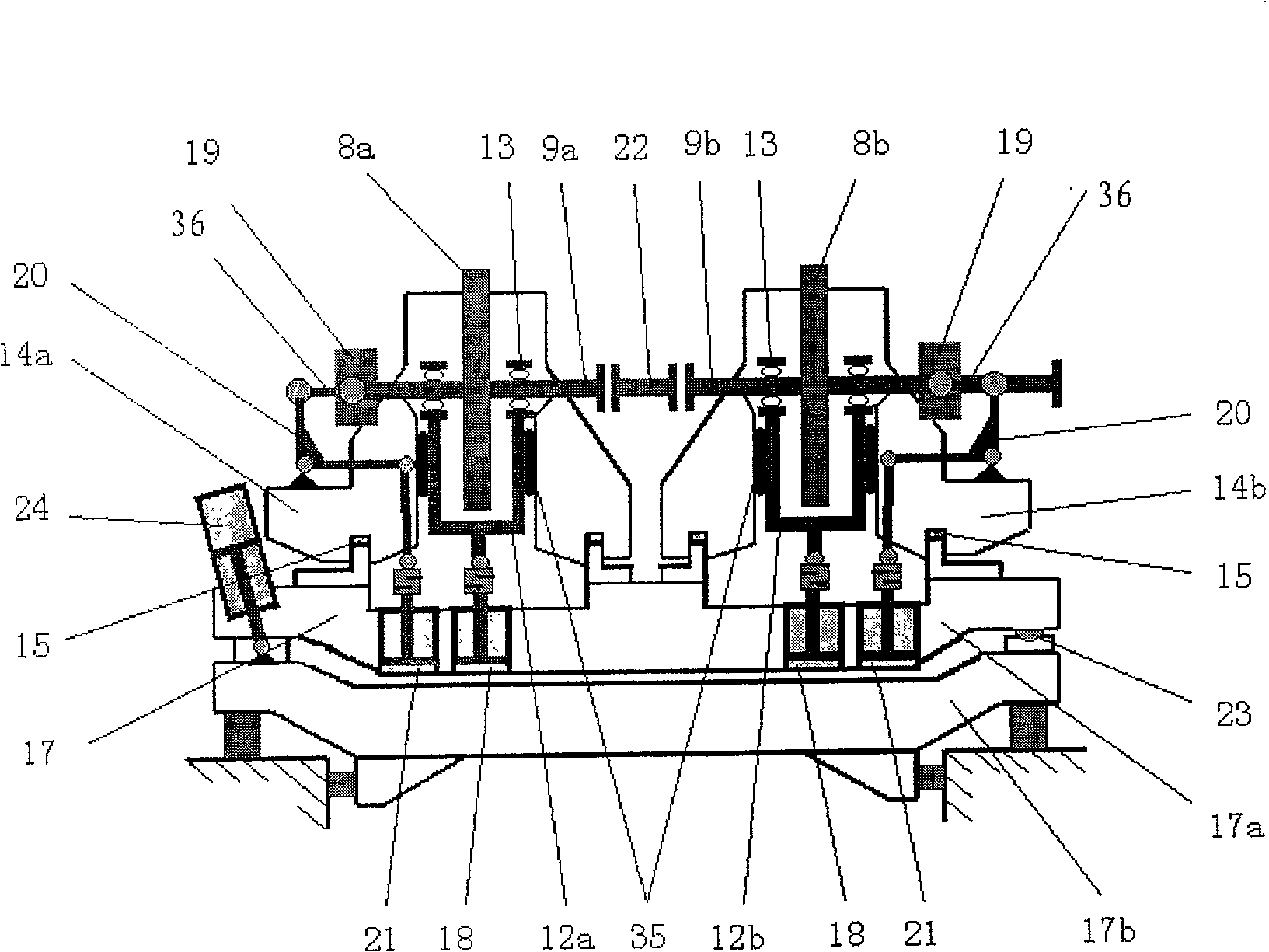

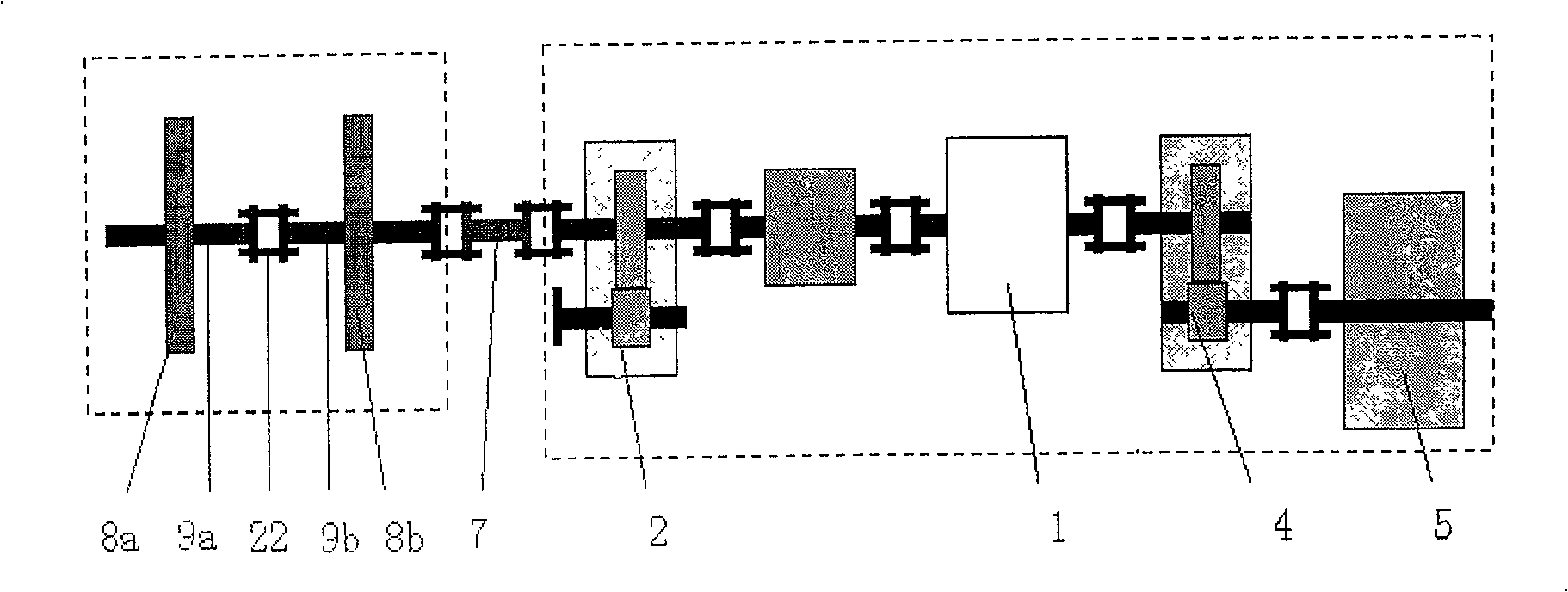

[0037] figure 1 , figure 2 and Figure 5 Shown, a kind of specific embodiment of the present invention is:

[0038] A railway locomotive vehicle operation simulation test bench is composed of several test units, and the specific structure of each test unit is:

[0039] The driving mechanism is connected to the right roller shaft 9b through the cardan shaft 7, and the left roller shaft 9a is connected to the right roller shaft 9b through a floating coupling 22; or the left roller shaft 9a is connected to the differential transmission mechanism of the driving mechanism; The right rollers 8a, 8b are installed on the left and right roller shafts 9a, 9b respectively.

[0040] Left and right roller shafts 9a, 9b are supported on left and right U-shaped frames 12a, 12b by bearings 13 respectively; Right roller seat 14a, 14b inner wall; Left and right roller seat 14a, 14b are all installed on the base 17.

[0041] The bottoms of the left and right U-shaped frames 12a, 12b are co...

Embodiment 2

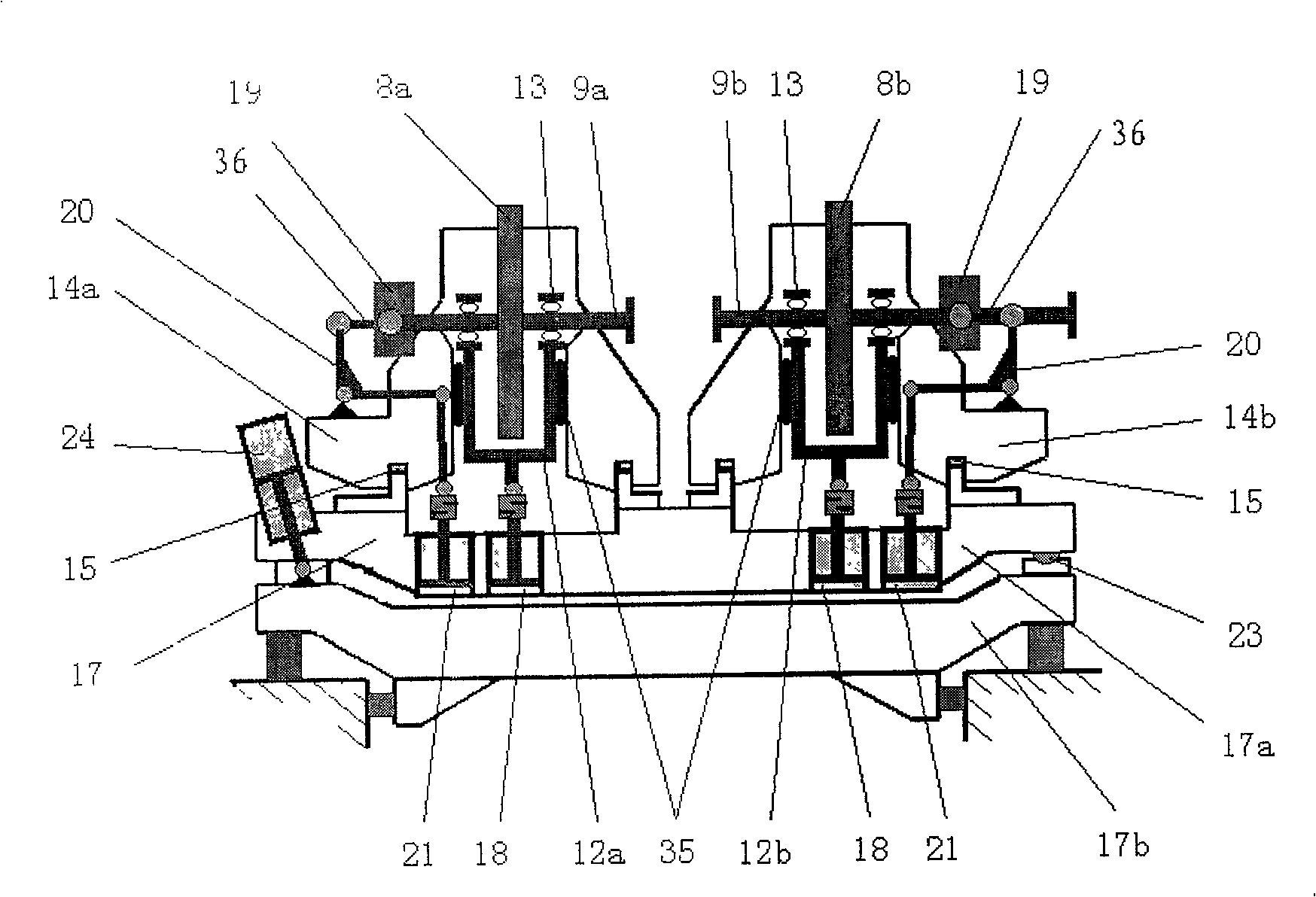

[0051] image 3 , Figure 4 and Figure 5 Shown, this embodiment is basically the same as Embodiment 1, except that the floating coupling (22) between the left roller shaft (9a) and the right roller shaft (9b) is removed. Instead, the left roller shaft 9a is connected to the differential transmission mechanism of the drive mechanism; the drive mechanism is composed of: the motor 1 is connected to the synchronous shunt gear box 2', and the synchronous shunt gear box 2' is directly output in the same direction as the motor 1 shaft The end is connected with the right roller shaft 9b through the cardan shaft 7; the synchronous output end perpendicular to the direction of the motor shaft is docked with the synchronous output end of the synchronous shunt gearbox 2' of the adjacent test unit, and the vertical output end perpendicular to the direction of the motor shaft It is connected with the left roller shaft 9a through a differential transmission mechanism. The composition of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com