Image display apparatus and high voltage driver circuit

A technology of image display device and driver circuit, which is applied in image communication, static indicator, color signal processing circuit, etc., can solve the problems of limiting the speed of push-pull level, which is not conducive to driving display screen devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

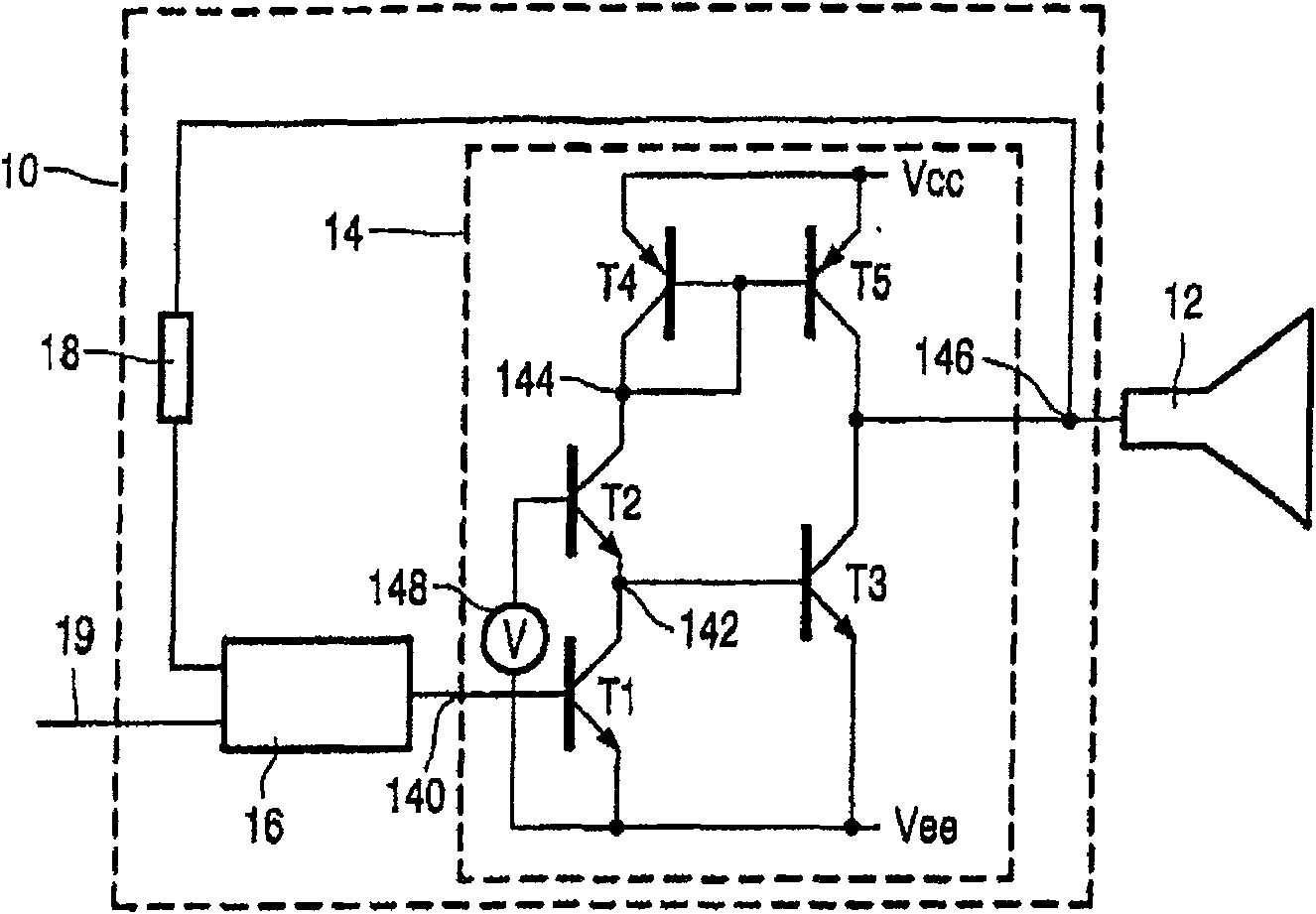

[0026] figure 1 An image display device is shown having a driver circuit 10 comprising a driver stage 14 , a preamplifier 16 and a feedback circuit 18 and a display screen assembly 12 of a CRT. The input 19 of the driver circuit 10 is connected to an input of a preamplifier 16 having an output connected to the input of the driver stage 14 . The output of the driver stage 14 is connected to a control electrode of the image display device 12 and to a further input 19 of a preamplifier 16 via a feedback circuit 18 . The driver stage 14 comprises an input transistor T1 of NPN type, a control transistor T2 of NPN type, a pull transistor T3 of NPN type and a current mirror T4, T5 having a mirror input transistor T4 of PNP type and a mirror output transistor of PNP type T5, the input 140 of the driver stage 14 is connected to the control electrode of the input transistor T1. The main current channel of the input transistor T1 is connected between the first power supply Vee and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com