Calorimeter having barrelhead with flow guiding circulating temperature controlling device

A technology of temperature control device and diversion cycle, which is applied in the field of calorimeters, can solve the problems of reduced accuracy of test results, uncertain degree of intensity, poor reproducibility, etc., and achieve shortened test time, strong reproducibility, and improved adaptability The effect of harsh environment capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

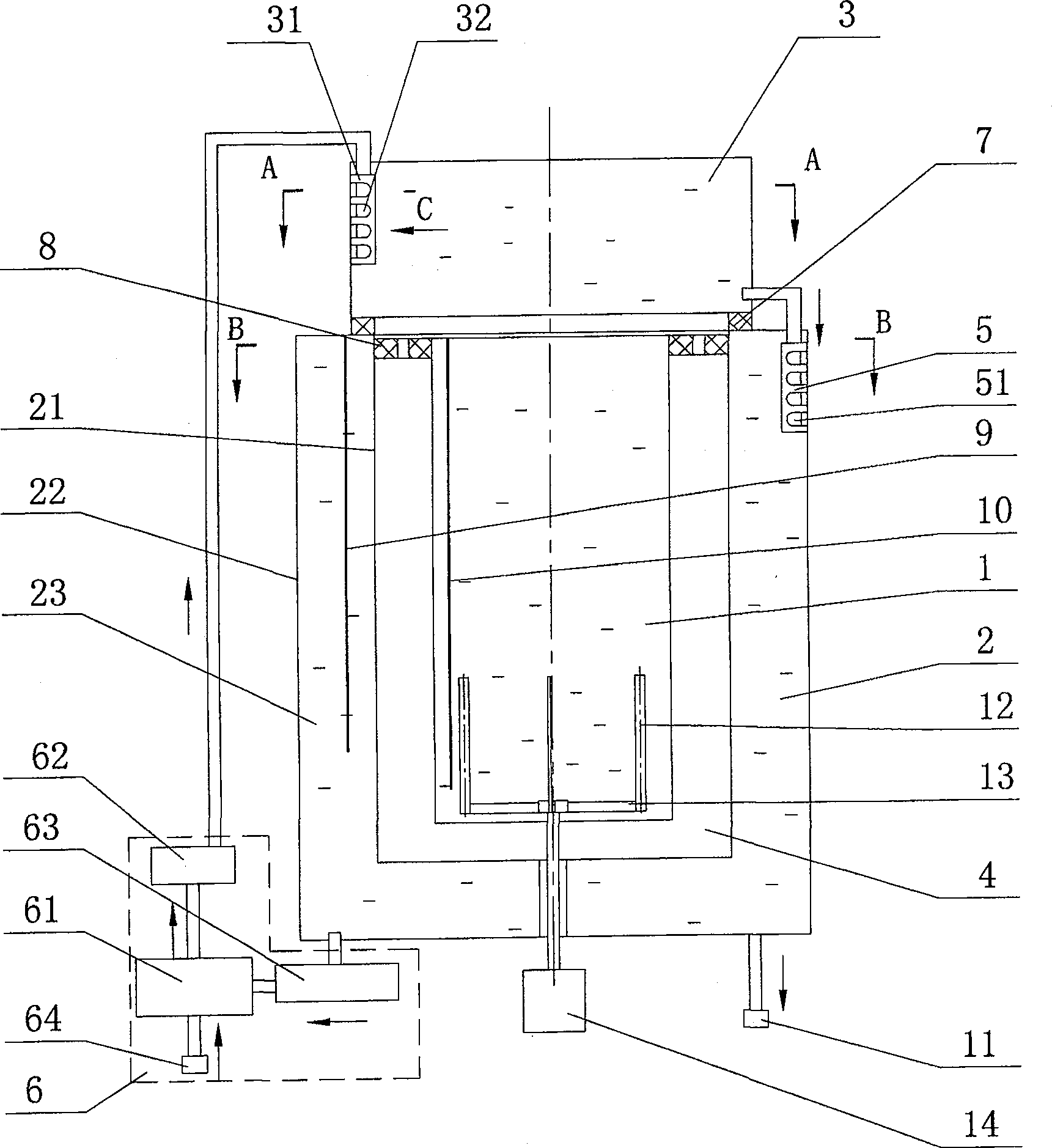

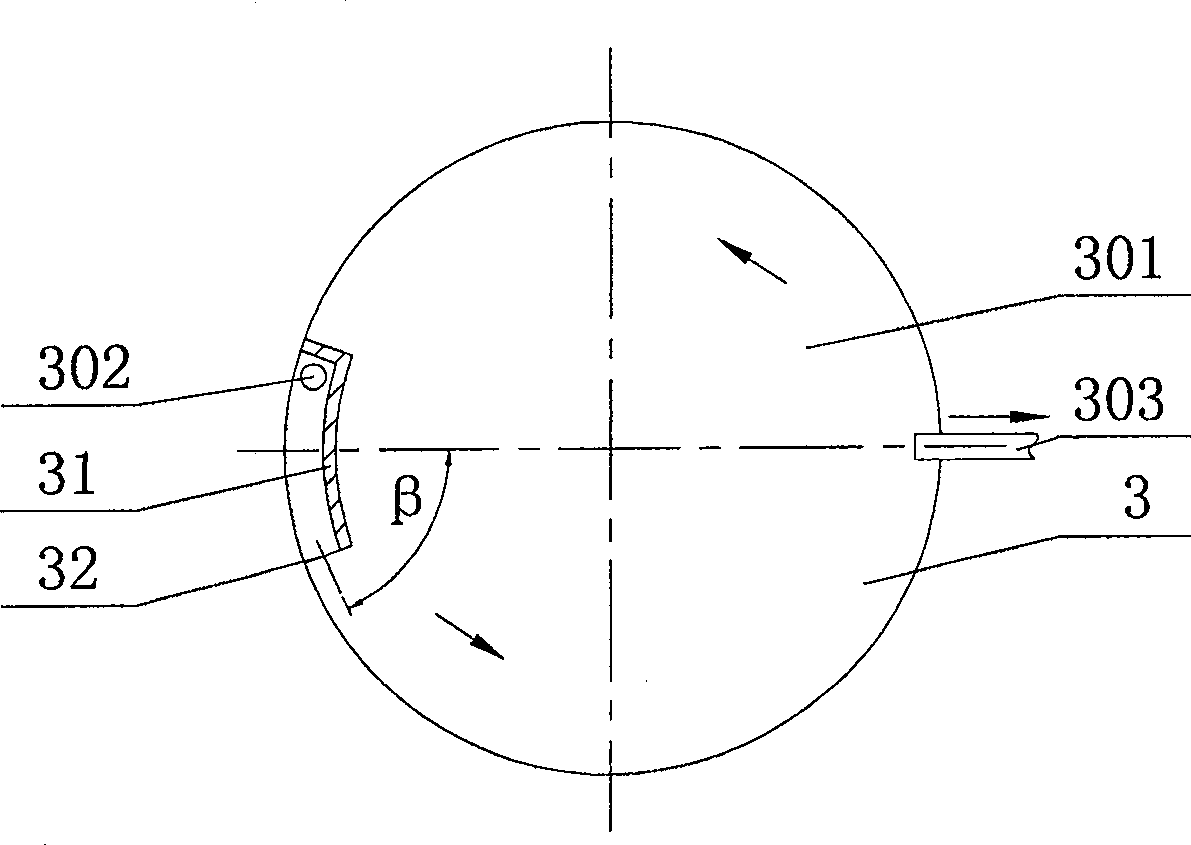

[0056] Embodiment 1: as figure 1 , figure 2 and Figure 4 As shown, one or more cover guide chambers 31 are provided in the bung 3, and several cover guide chamber openings 32 are provided on the cover guide chamber 31; the entrance of the cover guide chamber 31 and the cover medium inlet 302 The mouth of the cover guide cavity 32 is in communication with the entrance of the cover guide cavity 31 . The medium can be sprayed into the cover cavity 301 from the cover diversion cavity 32, and the medium in the cover cavity 301 is continuously pushed forward by the injection medium, thereby forming the self-flow agitation of the medium, and reaching the temperature trend of each place in the cover cavity 301. to a consistent effect. Wherein the lid diversion cavity 32 can adopt circular hole shape, slit shape or other irregular shapes according to the concrete needs of spraying, also can be by changing the α1 angle that lid diversion cavity 32 and bung 3 upper planes form in ad...

Embodiment 2

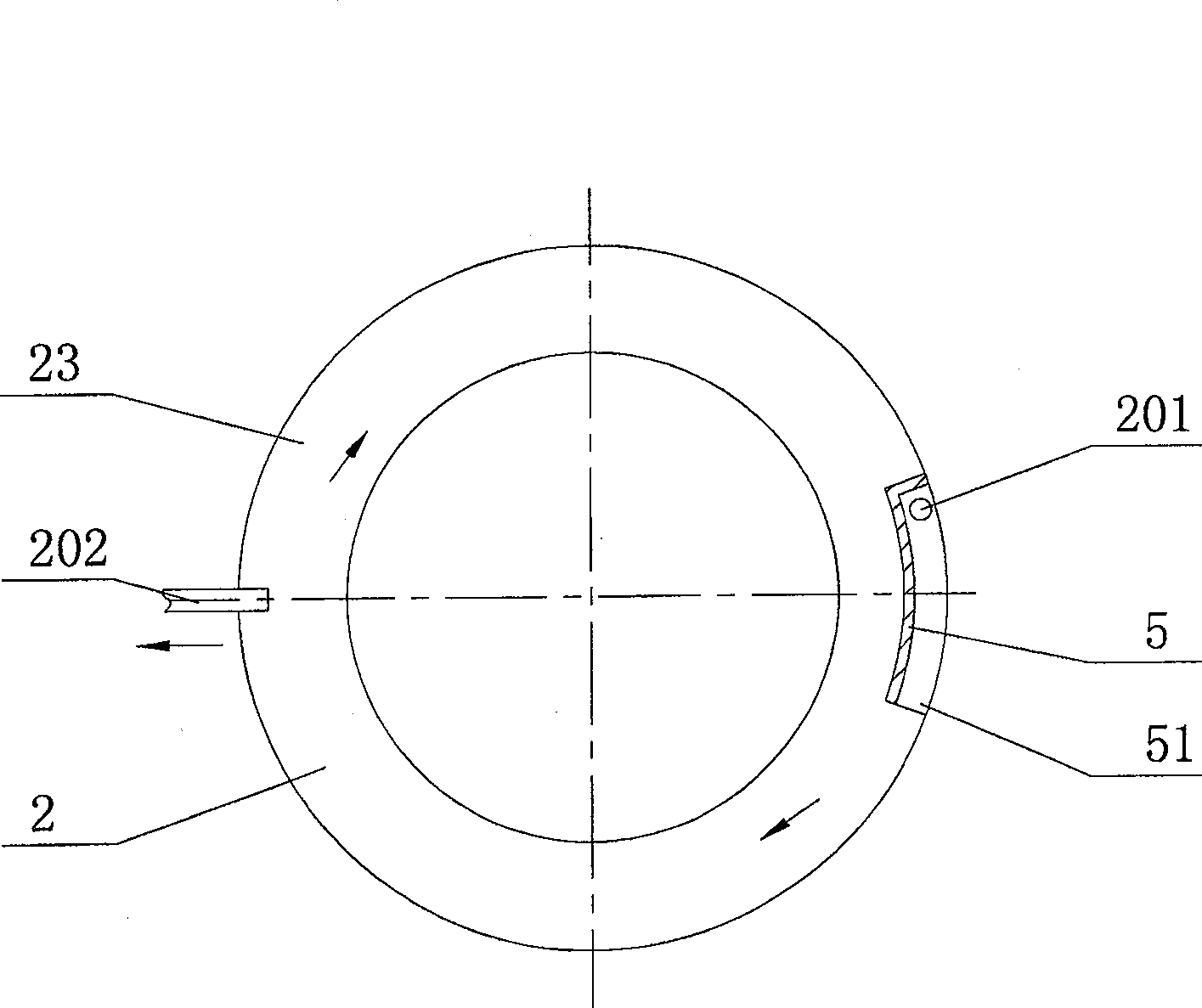

[0057] Embodiment 2: as Figure 6 , Figure 7 , Figure 9 , Figure 10 and Figure 12 As shown, one or more cover deflectors 33 are provided in the barrel cover 3, and the cover guide body 33 is centered on the center of the barrel cover 3, and is spirally distributed in the cover cavity 301 in the shape of an equal or non-equal diameter arc. Inside, and form a non-closed lid diversion groove 34 with the side wall of the barrel lid 3; the starting point of the lid diversion body 33 is located below the lid medium inlet 302. The medium enters the cover cavity 301 from the cover medium inlet 302. Under the diversion restriction of the cover guide body 33, part of the medium will flow along the cover guide groove 34, and then drive other media to flow in a certain direction, forming the self-flow of the medium Stir to achieve the effect that the temperature in the lid cavity 301 tends to be consistent everywhere. Among them, the cover diversion body 33 can change the α2 angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com