Seamless knitted clothes

A clothing and knitting technology, which is applied in the field of seamless knitted clothing, can solve the problems of fat and ill-fitting clothing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

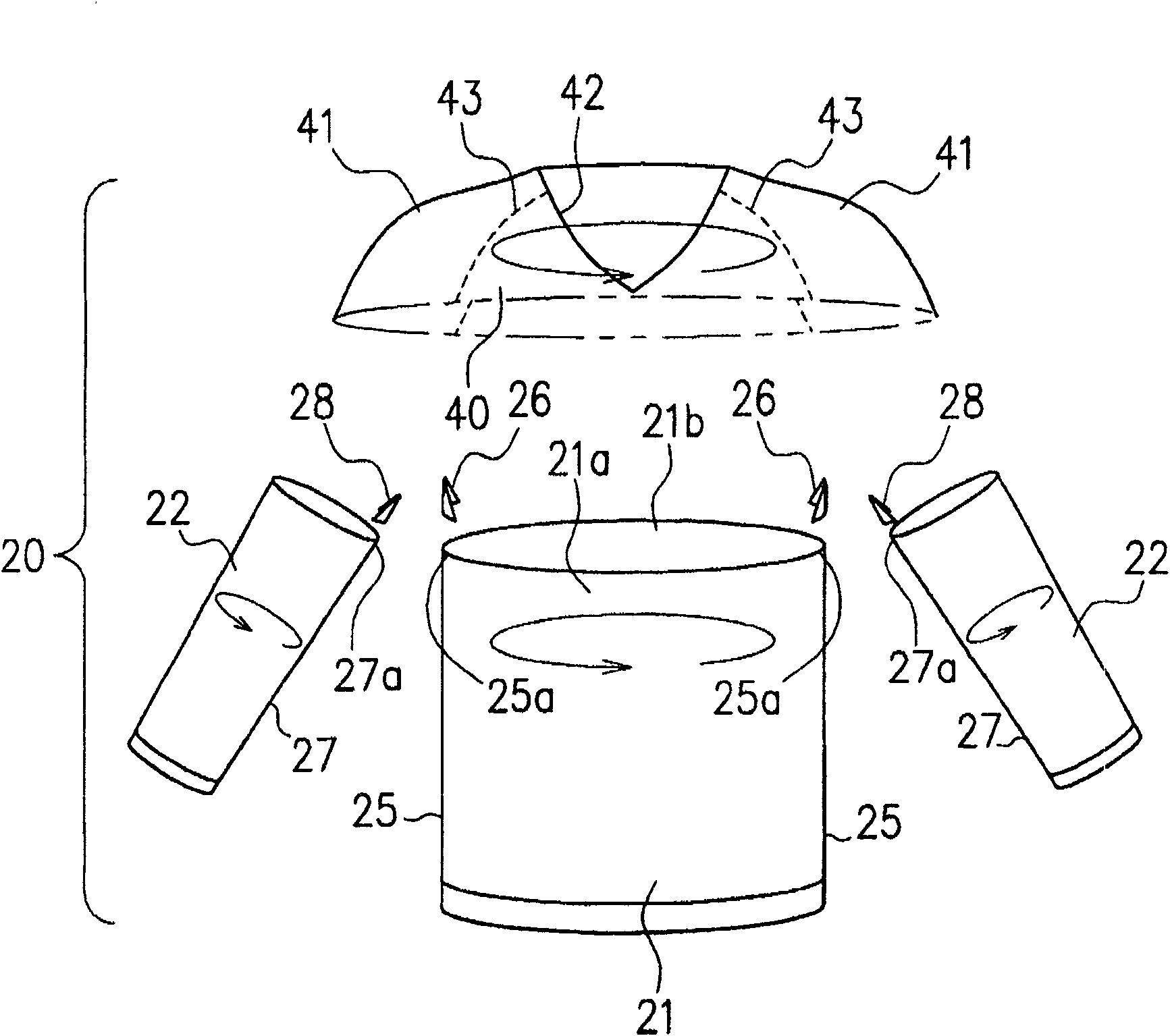

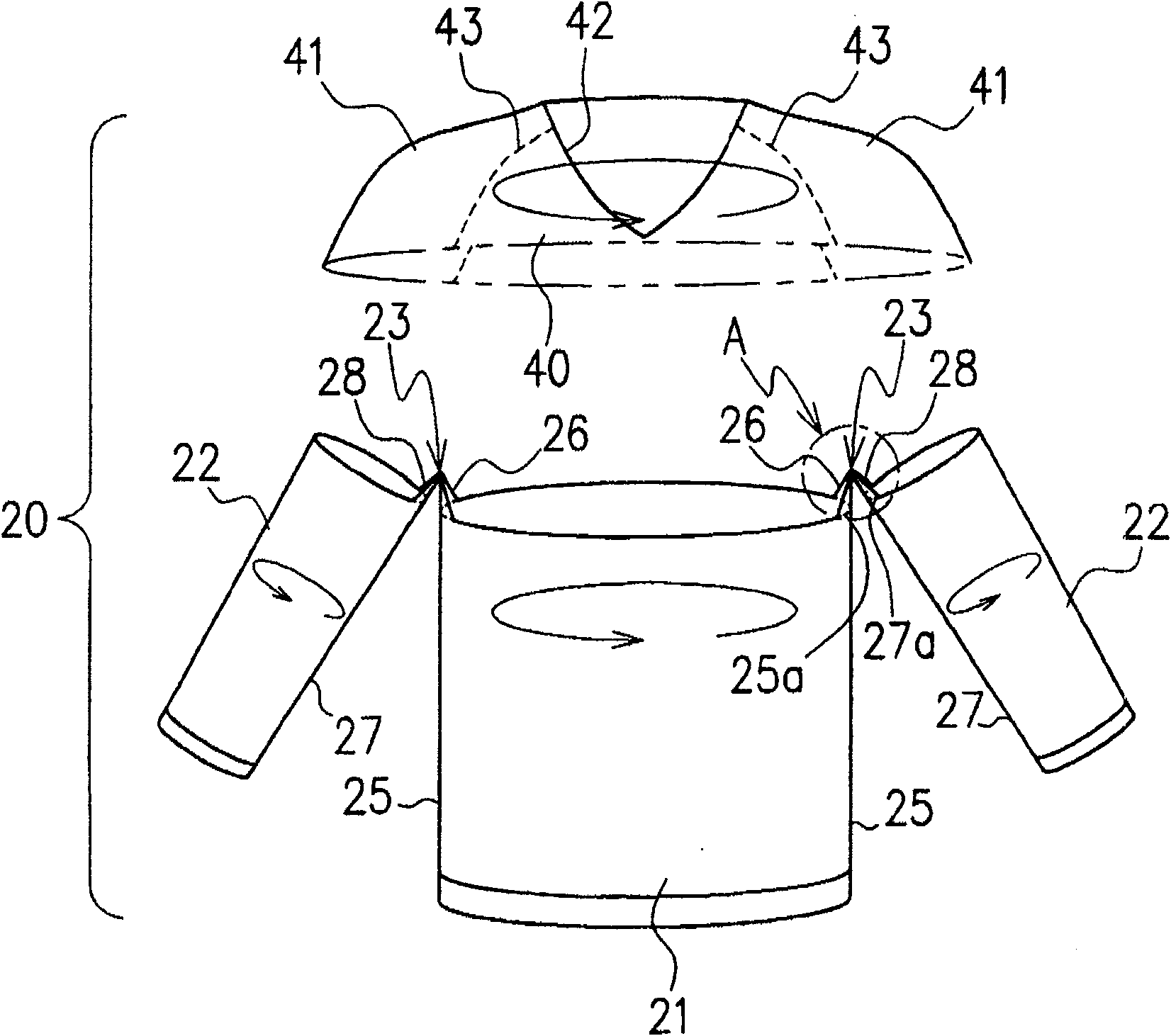

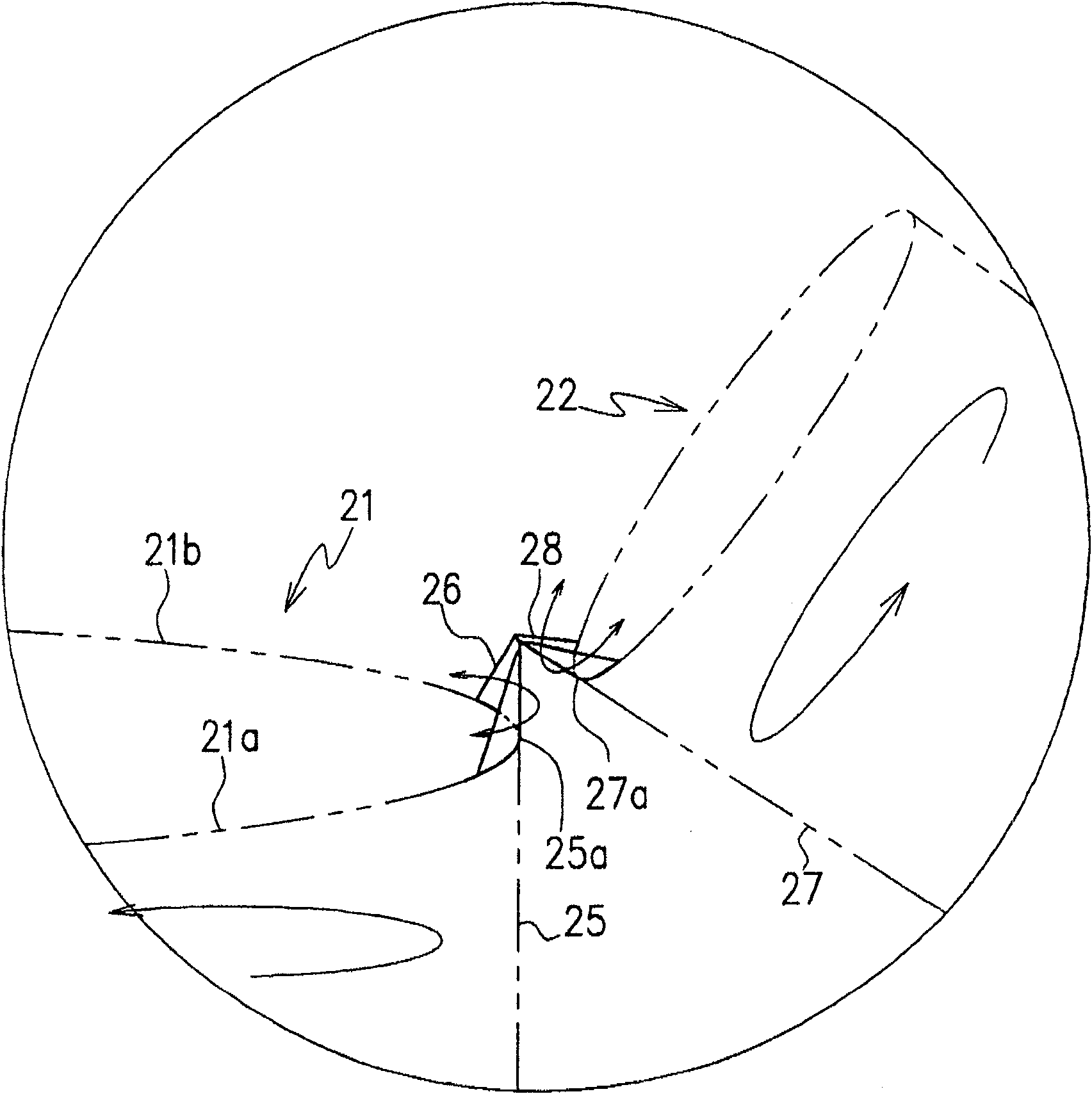

[0044] Hereinafter, embodiments of the seamless knitted garment according to the present invention will be described in detail with reference to the drawings. Figure 1 to Figure 6 Shown is the first embodiment when the seamless knitted garment according to the present invention is manufactured as raglan sleeve underwear. The underwear 20 related to this embodiment, such as figure 1 and figure 2 As shown, at first, use different knitting needles to form the body part 21 of the front and rear body parts and the sleeve bottom seam part 22 of the pair of left and right respectively into a cylindrical shape, and after joining the two at the shoulder joint 23 as the shoulder lifting part, The collar shoulder 40 and the sleeve shoulder 41 of the front and back body are knitted into a peripheral shape with common knitting needles, and the collar pocket 42 is finally processed and completed. In addition, when the neck shoulder portion 40 and the sleeve shoulder portion 41 are knit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com