Shaping tool and method of using same

A tooling and frame technology, applied in the field of automotive plastic products, can solve the problems of high rib density, high return rate, thick structural ribs, etc., and achieve the effect of simple structure and good shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

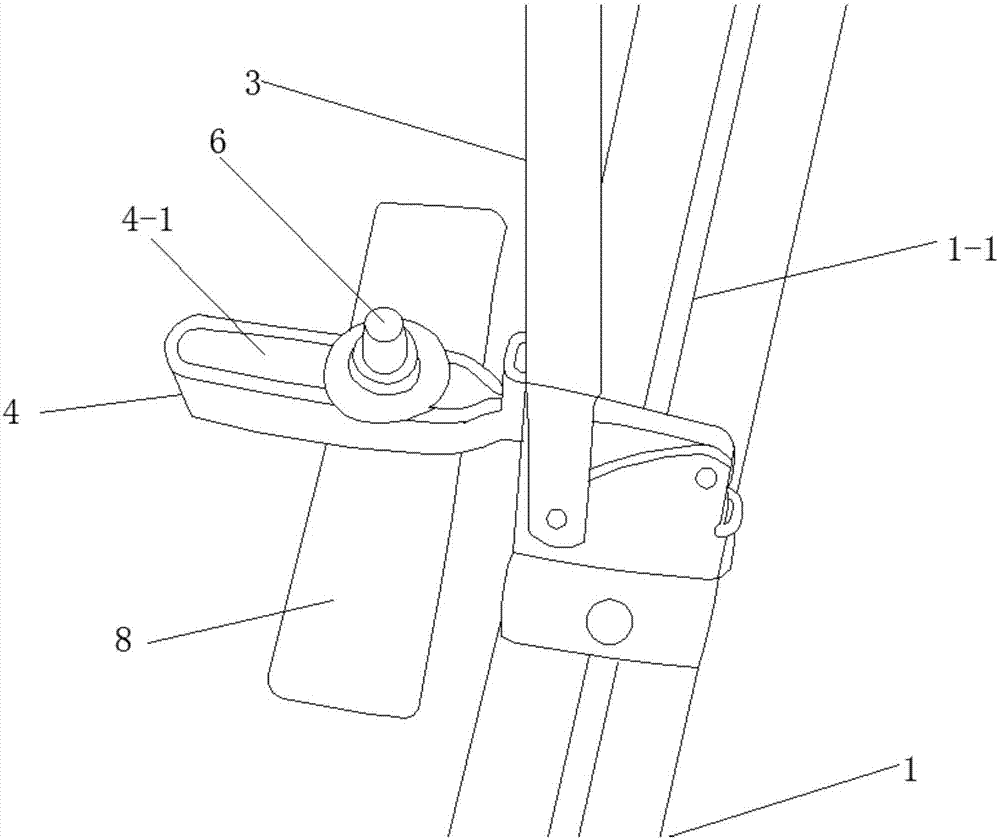

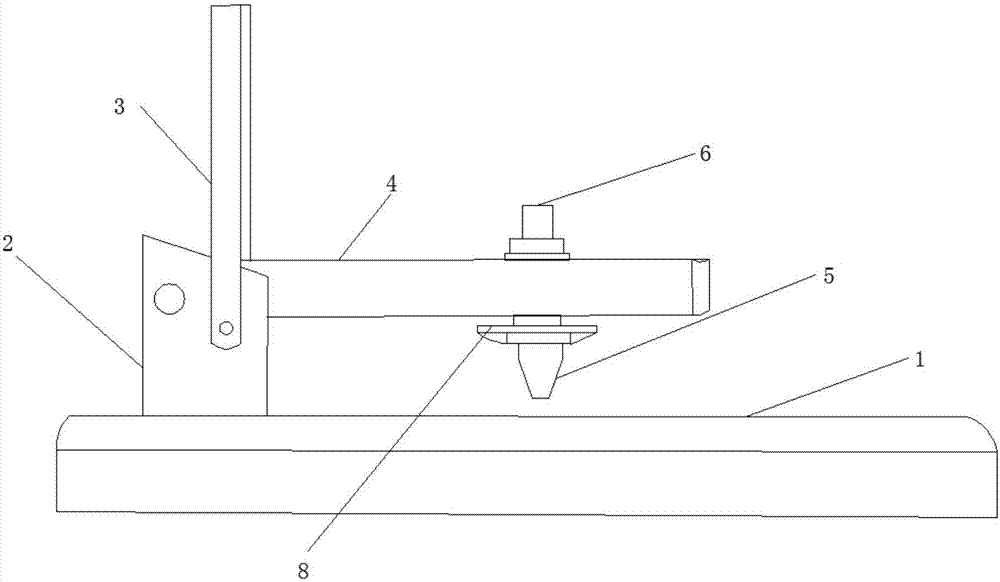

[0022] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] A sizing tooling of this embodiment includes a frame body 1. The frame body 1 is provided with a number of correcting components. The correcting component includes a sizing indenter and a sizing tablet 8. One end of the sizing indenter is connected to the frame body 1, and the sizing indenter The other end of is fixedly connected to one side of the shaped pressing plate 8.

[0024] The shaping indenter is provided with a handle 3, an adjustment block 4 and a pressure block. The upper end surface of the frame body 1 is fixed with a support part 2, and the lower end of the handle 3 is provided with an escape part 3-1, and both sides of the escape part 3-1 The walls are respectively hingedly connected to the supporting part 2, one end of the adjusting block 4 passes through the lower end of the avoiding part 3-1 and then hinged to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com